Forming correcting manufacturing method for reinforcing plate under stainless steel side wall window

A manufacturing method and reinforcing plate technology, which are applied in the field of stamping technology, can solve the problems of difficult forming and inability to meet production needs, and achieve the effects of low adjustment and repair efficiency, improvement of one-time forming quality, and improvement of correction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

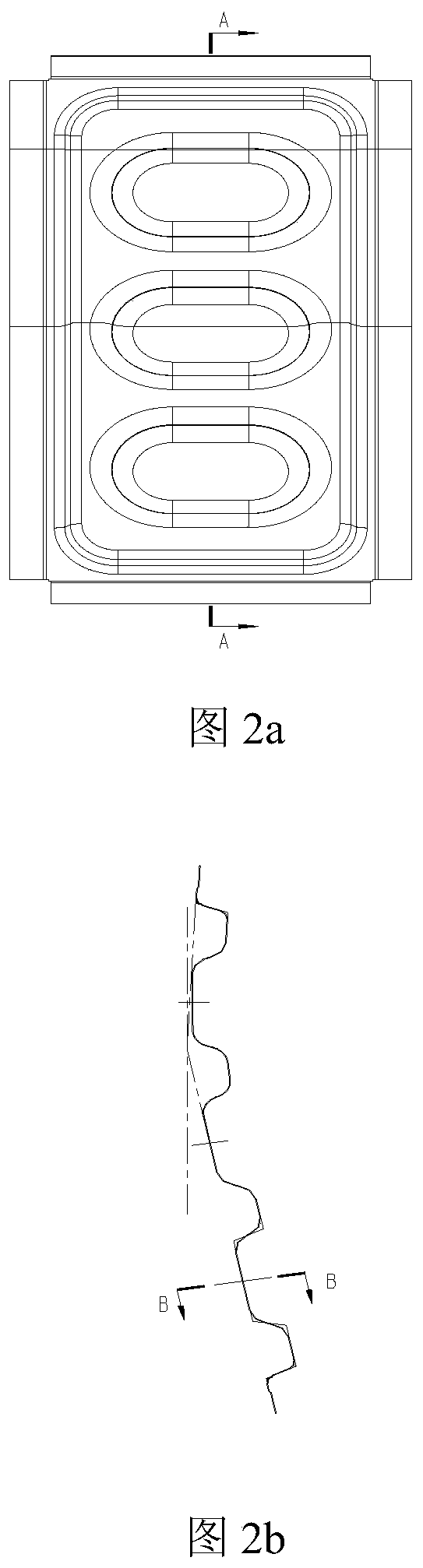

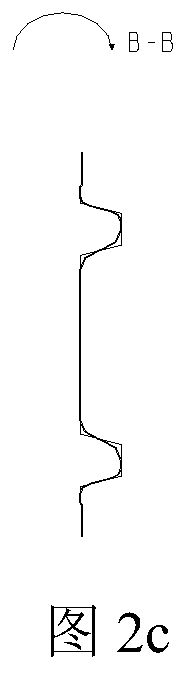

[0024] Specific implementation mode 1. Combination Figure 1 to Figure 5 Describe this embodiment, a method for forming and correcting the reinforcement plate under the window of the stainless steel side wall, the method is realized by the following steps:

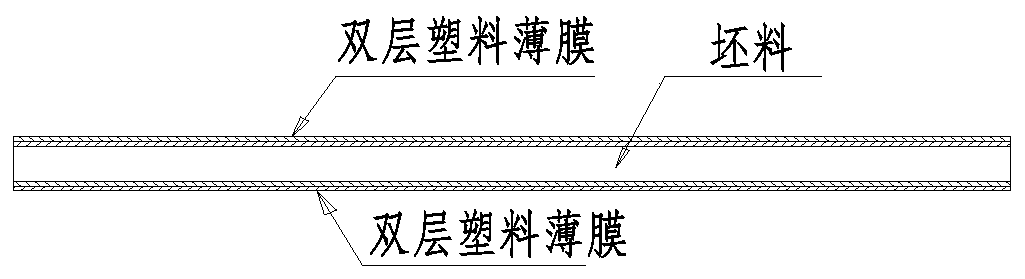

[0025] 1. Innovate the drawing lubricating medium, and use film protection for drawing forming, such as figure 1 , The raw material does not have a film, it is placed before drawing and forming, and the workpiece will crack without adding a film. Therefore, double-layer plastic films are used on the upper and lower sides of the blank.

[0026] During the drawing forming process of the mold, the double-layer plastic film is placed on the upper and lower sides of the blank to obtain the formed part, which not only meets the lubrication function during the drawing process, but also protects the surface of the mold and the part surface. The double-layer plastic film can ensure that the material is fully and evenly extended, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com