A kind of n-type passivated contact cell and its preparation method

An n-type battery technology, which is applied in the manufacture of circuits, electrical components, and final products, can solve the problems of reduced production capacity, reduced utilization of long-wavelength light, and complicated steps, so as to increase open circuit voltage and short circuit current and reduce equipment costs. The effect of investment and reduction of preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

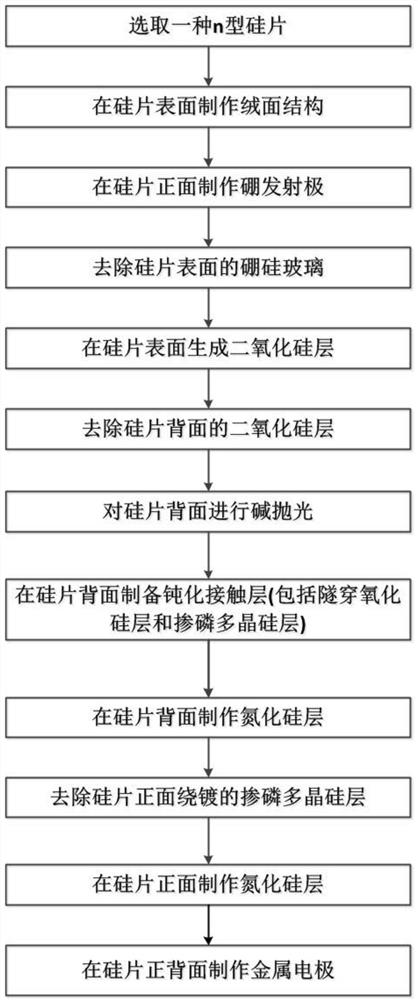

[0042] combine figure 1 , the invention provides a kind of n-type passivated contact battery preparation method, mainly comprises the following steps:

[0043] Step 1: Select an n-type silicon wafer.

[0044]Step 2: Prepare the texture required for the battery on the surface of the n-type silicon wafer. Different texturing methods are selected according to different types of silicon wafers, and the specific preparation methods are not limited. For example, alkali texturing is used to prepare positive pyramid-shaped texture on the surface of silicon wafers, or a catalytic method is used to prepare inverted pyramid-shaped textures on the surface of silicon wafers.

[0045] Step 3: preparing a boron emitter on the front side of the silicon wafer. Optionally, the boron emitter on the front side can be a uniform emitter or a selective emitter. The specific preparation method of the boron emitter is not limited, for example, one or more of methods such as furnace tube boron diffu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com