A paint spraying device for a coat rack rod

A coat rack and sliding rod technology, applied in the direction of spraying devices, etc., can solve the problems of manpower consumption, low work efficiency, cumbersome operation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

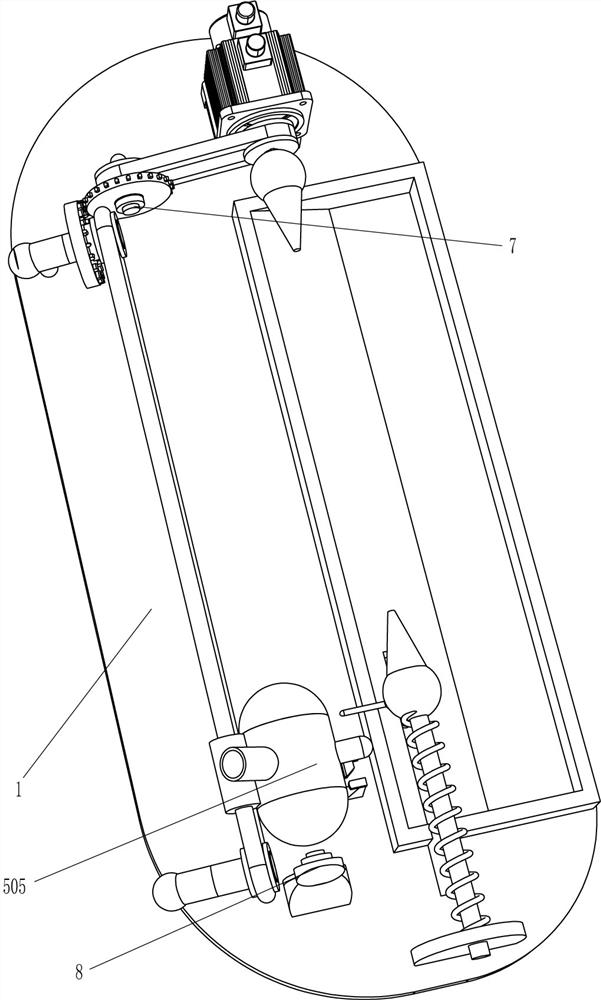

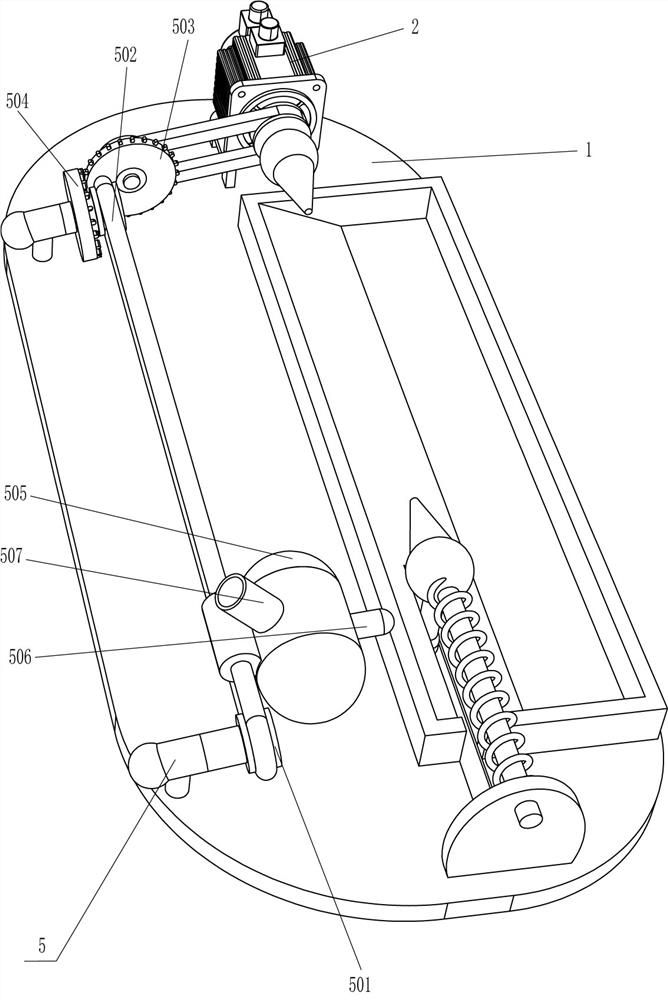

[0025] A painting device for a coat rack rod such as Figure 1-2 As shown, it includes a base 1, a motor 2 and a material guide frame 3, the motor 2 is installed on the rear side of the top of the base 1, the material guide frame 3 is connected to the top right side of the base 1, and a clamping mechanism 4 and a painting mechanism 5 are also included. The base 1 is provided with a clamping mechanism 4 and a painting mechanism 5 .

[0026] The clamping mechanism 4 includes a card seat 401, a first slide bar 402, a pressure spring 403 and a fixing seat 404. The front side of the top of the base 1 is slidably connected to a first slide bar 402, and the rear end of the first slide bar 402 is connected to a card seat. 401 , a pressure spring 403 is connected between the first slide bar 402 and the base 1 , and a fixed seat 404 is connected to the output shaft of the motor 2 , and the fixed seat 404 cooperates with the card seat 401 .

[0027] The painting mechanism 5 includes a s...

Embodiment 2

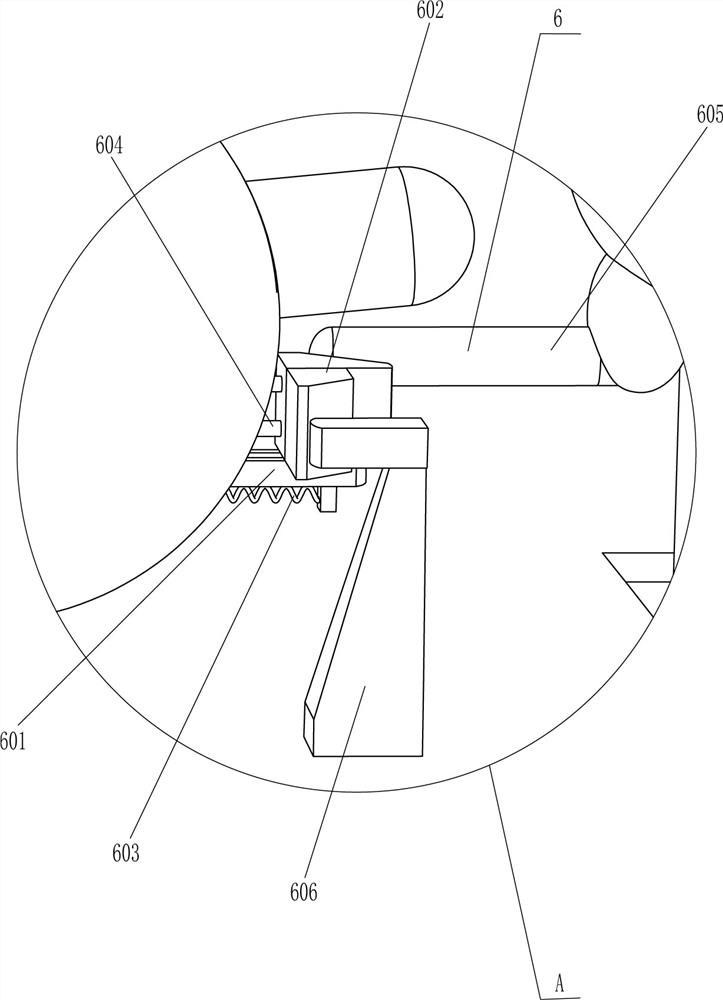

[0030] On the basis of Example 1, such as Figure 3-4 As shown, a discharge mechanism 6 is also included. The discharge mechanism 6 includes a horizontal plate 601, a wedge block 602, an elastic member 603, a second slide bar 604, a pull bar 605 and an oblique bar 606. The right side of the barrel 505 is connected with A horizontal plate 601, a wedge block 602 is slidably connected to the horizontal plate 601, an elastic member 603 is connected between the wedge block 602 and the horizontal plate 601, a second slide bar 604 is connected to the bucket 505, the second slide bar 604 and the wedge The block 602 is slidingly fitted, and the first slide bar 402 is connected with a pulling rod 605, which will contact the wedge-shaped block 602, and the front side of the top of the base 1 is connected with a slanting rod 606, which will contact the wedge-shaped block 602.

[0031] When the bucket 505 moves forward and backward, it drives all the devices on it to move forward and backw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com