A kind of automatic spraying equipment for batch production of paint panels

A mass production, automatic spraying technology, applied in spray booths, spray devices, etc., can solve the problems of uneven painting, damage to health, and low painting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

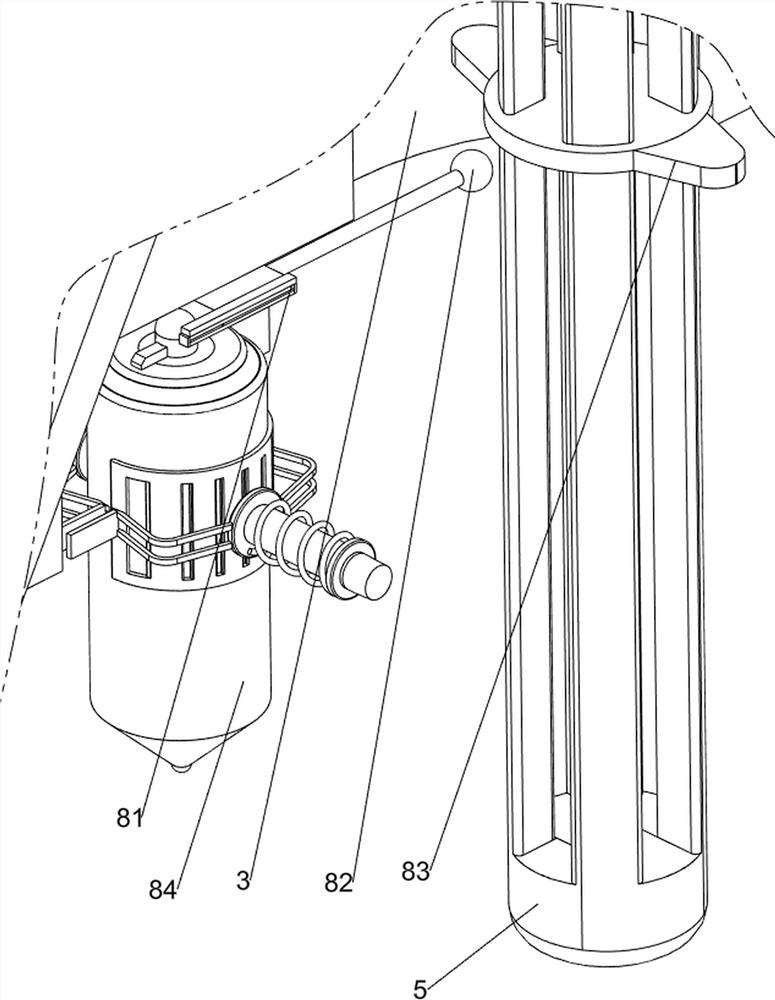

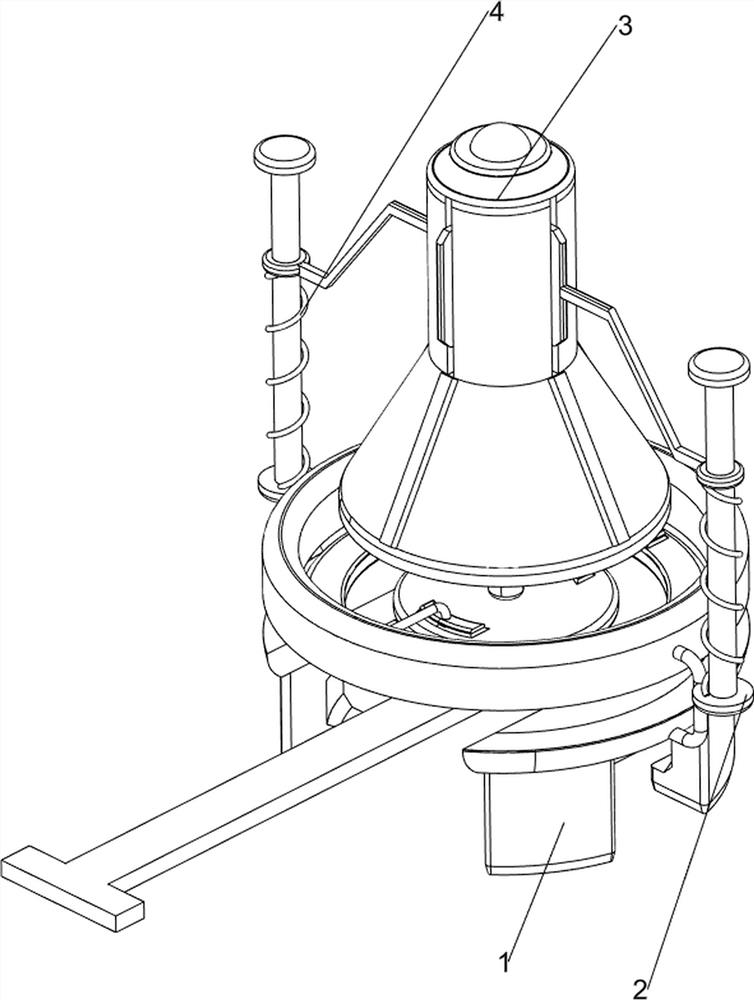

[0074] An automatic spraying equipment for mass production of lacquered panels, such as Figure 1-6 As shown, it includes a first support frame 1, a first sliding rod 2, a second support frame 3, a first spring 4, a motor 5, a first pallet 6, a clamping mechanism 7 and a painting mechanism 8. The first support frame 1. The left and right sides are provided with a first sliding rod 2, a second supporting frame 3 is slidably arranged between the upper parts of the two first sliding rods 2, and a first spring 4 is wound around the two first sliding rods 2. Two ends of a spring 4 are respectively connected with the first sliding rod 2 and the second support frame 3 , a motor 5 is installed on the inner side of the second support frame 3 , a first support plate 6 is arranged on the output shaft of the motor 5 , and the lower part of the second support frame 3 The inner side is provided with a clamping mechanism 7, and the clamping mechanism 7 is provided with a painting mechanism 8...

Embodiment 2

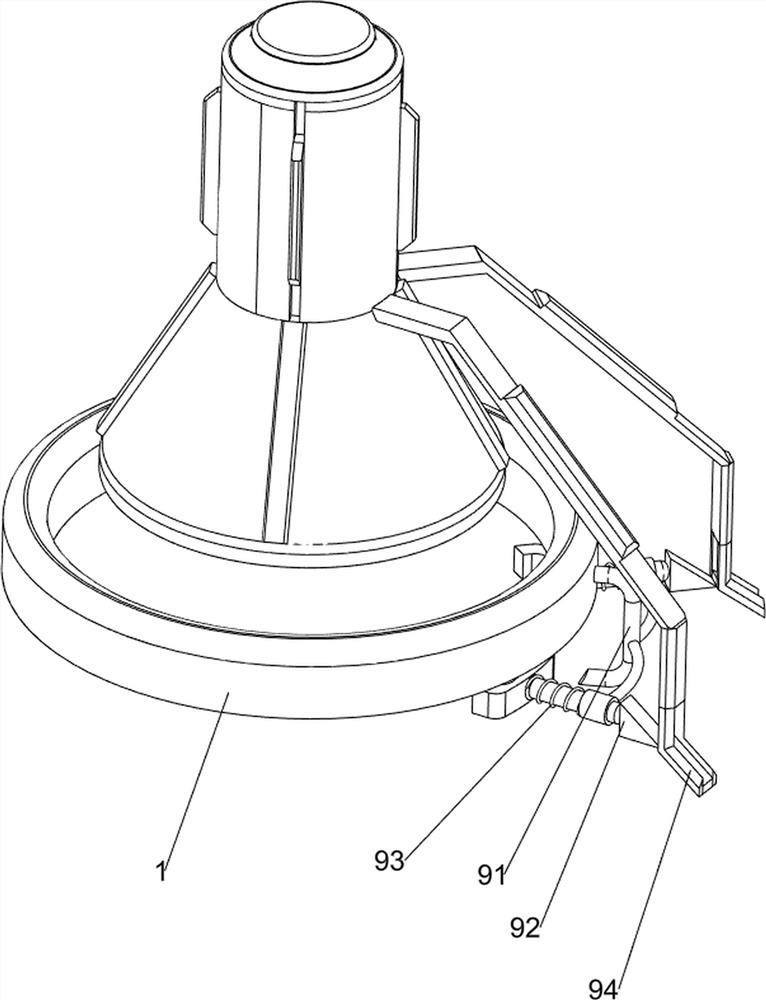

[0081] On the basis of Example 1, as Figure 7-10 As shown, it also includes a fixing mechanism 9. The fixing mechanism 9 includes a third support frame 91, a second wedge block 92, a fourth spring 93 and a third wedge block 94. The upper left and right sides of the first support frame 1 are provided with The third support frame 91, the middle of the two third support frames 91 are slidably provided with second wedge-shaped blocks 92 on both the front and rear sides. There is a third wedge block 94, the third wedge block 94 is in contact with the second wedge block 92, and a fourth spring 93 is wound around the four second wedge blocks 92, and the two ends of the fourth spring 93 are respectively connected with the third support frame 91. Connect with the second wedge block 92 .

[0082] When the second support frame 3 moves downward, the downward movement of the second support frame 3 drives the third wedge block 94 to move downward, and the third wedge block 94 contacts the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com