Microactuator, head suspension assembly and disk device

A micro-driver and connection pad technology, which is applied in the configuration of the head, the installation of the arm parts, the configuration/installation of the recording head, etc., can solve the problem of increased displacement of the piezoelectric element, increased gap between electrodes, electrode short circuit, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0029] As a disk device, a hard disk drive (HDD) according to the embodiment will be described in detail.

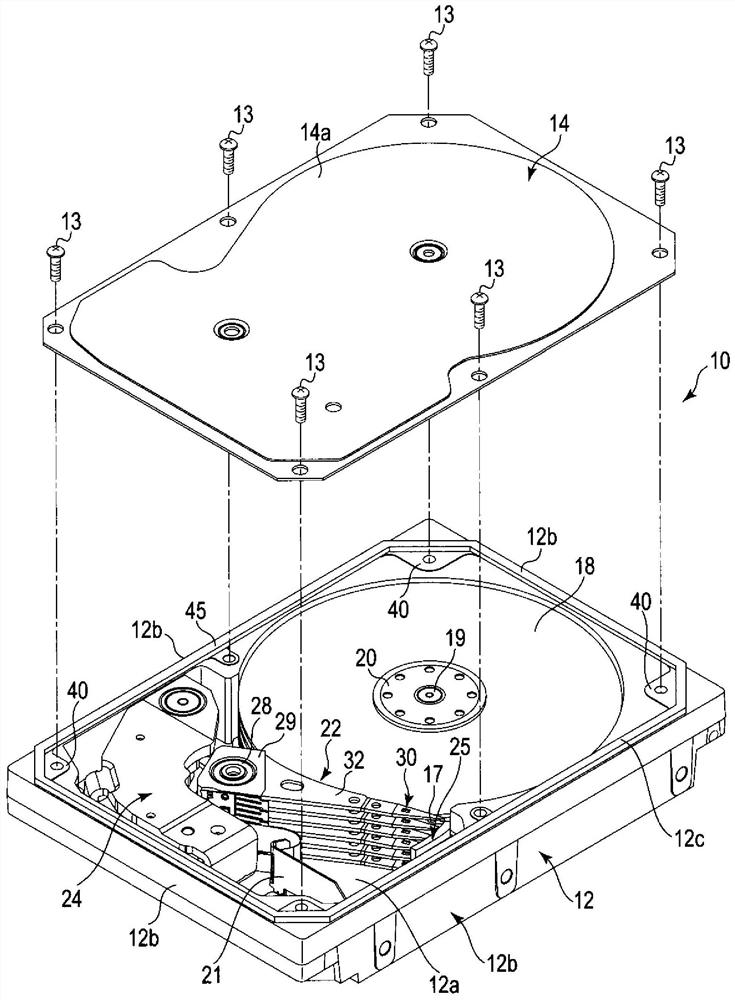

[0030] figure 1 It is an exploded perspective view of the HDD of the embodiment shown with the cover removed. As shown in the figure, the HDD includes a rectangular housing 10 . The housing 10 has a rectangular box-shaped base 12 with an open upper surface and a cover (top cover) 14 . The base body 12 has a rectangular bottom wall 12a and side walls 12b erected along the periphery of the bottom wall 12a, and is integrally formed of, for example, aluminum. The cover 14 is formed in a rectangular plate shape, for example, from stainless steel. The cover 14 is screwed to the side wall 12b of the base body 12 by a plurality of screws 13, and closes the upper opening of the base body 12 airtightly.

[0031] In the case 10, a plurality of, for example, five magnetic disks 18 are provided as a disk-shaped recording medium, and a spindle motor 19 that supports and rotates th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com