Precast concrete troweling device

A technology for concrete prefabricated parts and lifting devices, which is applied in the directions of manufacturing tools, auxiliary molding equipment, ceramic molding machines, etc., can solve the problems of large impact of the buffing head, slow production speed, and shortened service life, so as to improve the buffing quality, prolong the Service life, the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

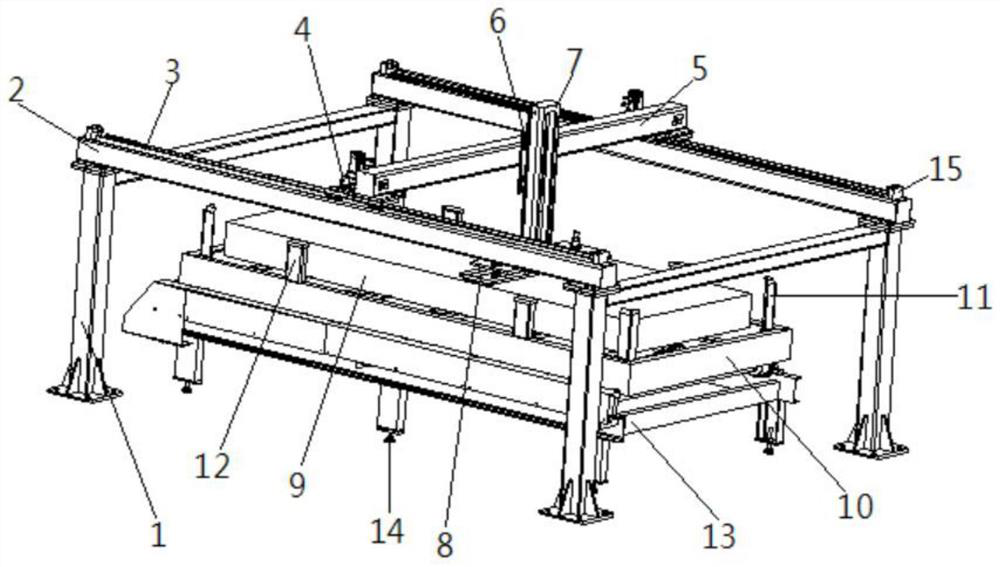

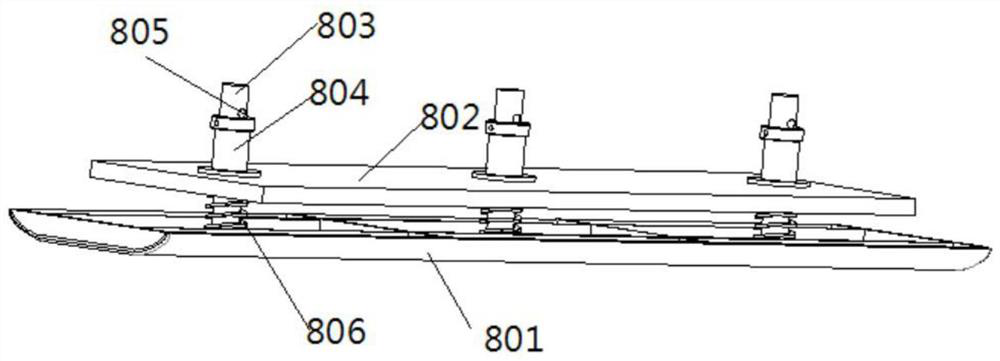

[0023] Such as Figure 1-2 Shown, the prefabricated concrete troweling device of the present invention includes a support movement mechanism, a mold transport mechanism and a troweling head; the specific structure is as follows:

[0024] The support movement mechanism comprises a gantry 1, and the gantry 1 is provided with two parallel longitudinal track beams 2, and the track beam 2 is provided with a first slide rail 3 along the length direction; Each end is equipped with a first slider 4, a first motor and a gear, the first motor is connected to the gear to drive the gear to rotate, the first slider 4 is slidably connected to the corresponding first slide rail 3, and the gear is connected to the corresponding rack teeth. The two ends of the walking beam 5 are thus connected to the two track beams 2; the middle part of the walking beam 5 is provided with a second motor 6, a lead screw and a second track, the lead screw is vertically arranged, and the second motor 6 drives th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com