A sealing structure for the upper end of an a-pillar

A sealing structure and sealing technology, which are applied to the superstructure, superstructure sub-assemblies, vehicle components, etc., to achieve the effects of improving stability, enhancing sealing effect, and improving sealing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

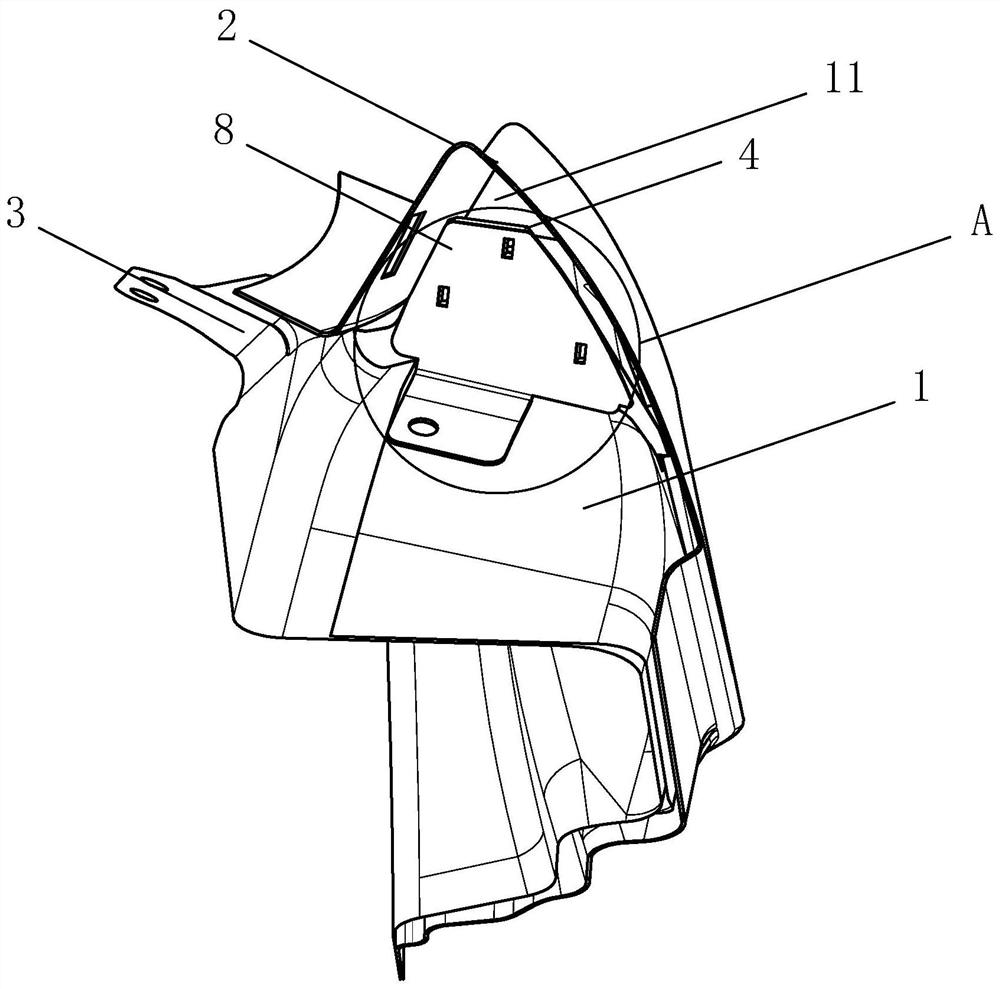

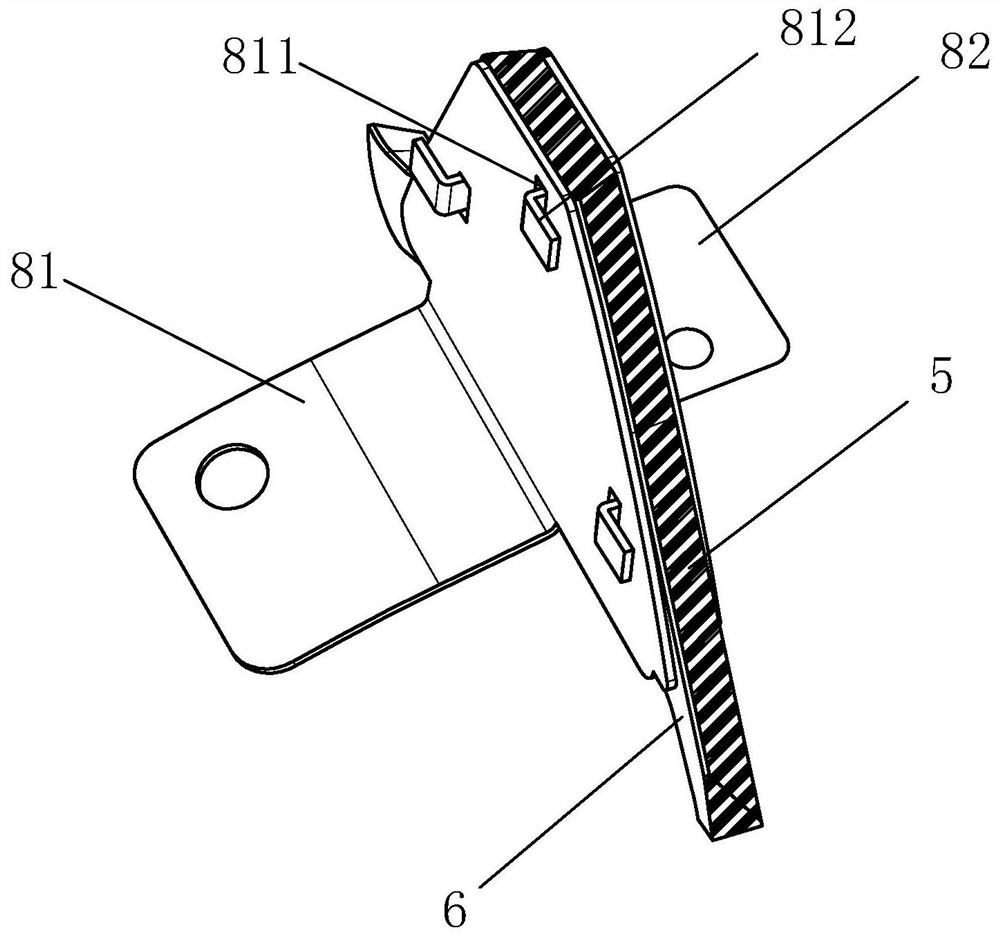

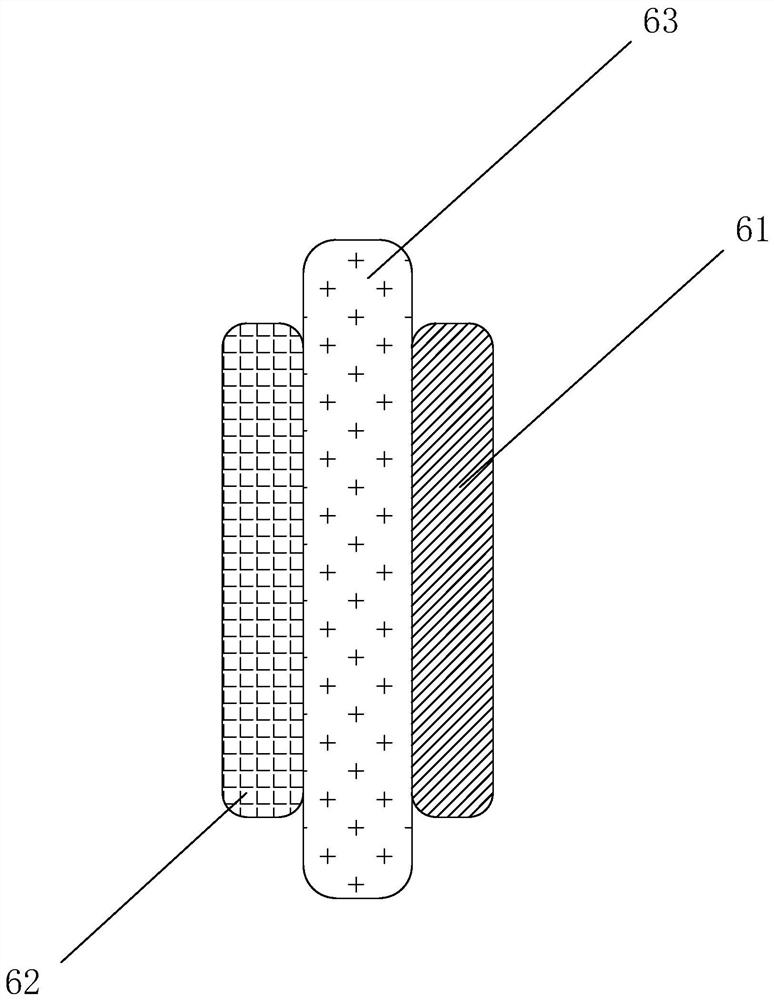

[0024] Such as figure 1 , 2As shown, a sealing structure at the upper end of the A-pillar includes an A-pillar reinforcement panel 1 and a side panel outer panel 2, an A-pillar inner panel 3 is arranged below the side panel outer panel 2, an A-pillar reinforcement panel 1 and a side panel outer panel 2 A composite seal 4 is arranged between them, a structural cavity 11 is formed between the A-pillar reinforcement plate 1, the side wall outer panel 2 and the A-pillar inner panel 3, the composite seal 4 is an expandable part, and the composite seal 4 A plastic sealing layer 5 is arranged on it, and the plastic sealing layer 5 fills the structural cavity 11 . The composite seal 4 can be expanded and deformed, and the extruded plastic seal layer 5 fills the structural cavity 11; due to the characteristics of the plastic material, when the composite seal 4 shrinks after expansion, the plastic seal layer 5 can still remain The deformed position maintains the sealing effect on the ...

Embodiment 2

[0031] The difference from Example 1 is that in this example, the expansion layer adopts a micro-airbag, and the micro-airbag is a sealed structure with sodium nitride inside. After the panel and the A-pillar reinforcement panel, the expansion layer is squeezed hard, the sodium nitride in the micro-airbag is decomposed into nitrogen and sodium simple substances, and the micro-airbag expands and squeezes the plastic sealing layer to fit the inner wall of the structural cavity , in turn to achieve long-term sound insulation sealing effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com