Flexible production process of wheel drive maintenance

A flexible production and process technology, applied in the field of flexible production technology for wheel drive maintenance, can solve the problems of large site requirements, high production costs, and inability to adapt to wheel drive maintenance of various specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with specific embodiments.

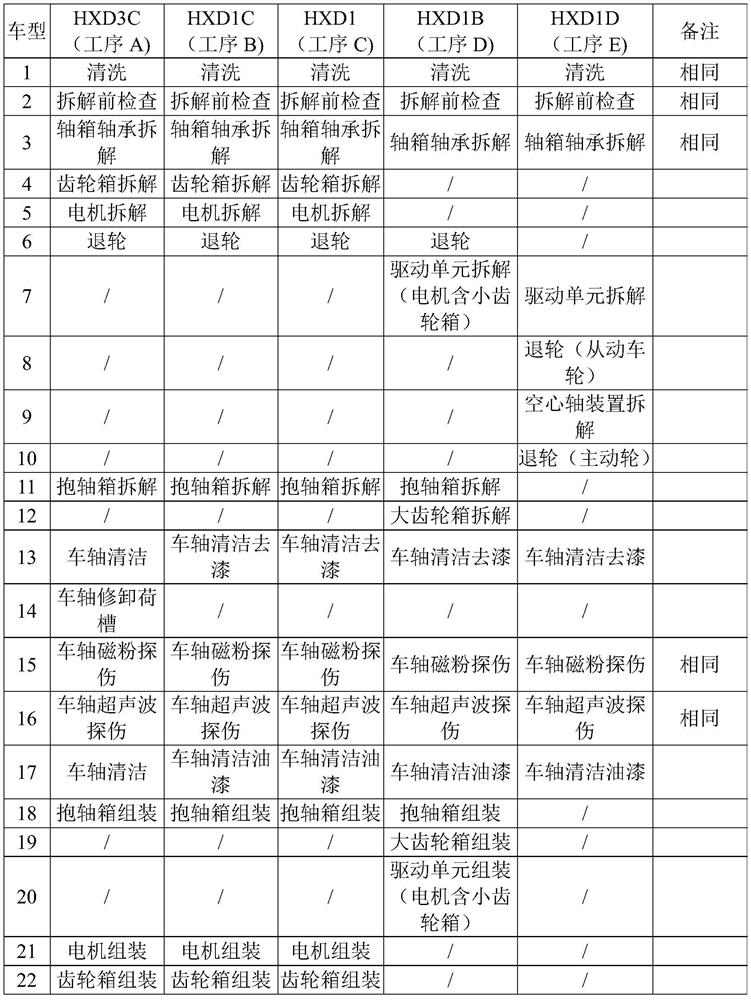

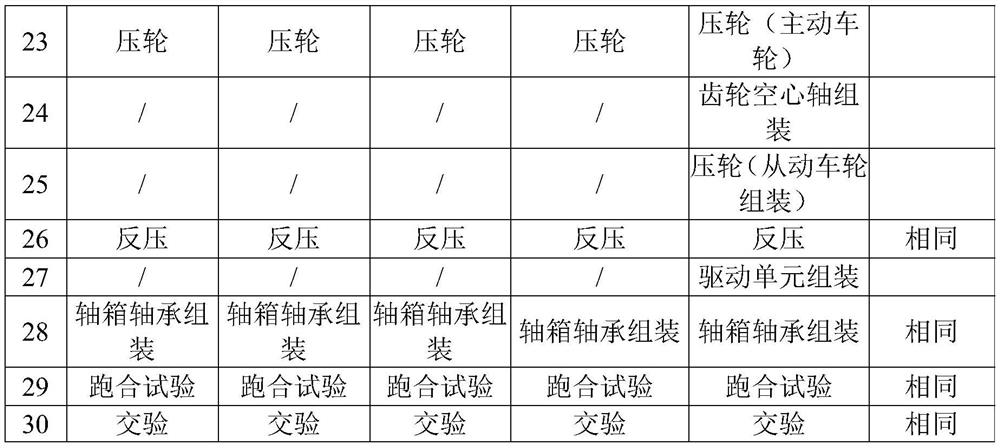

[0031] A flexible production process for overhauling wheel drives. Different procedures are set up according to different locomotive models. In the overhauling and overhauling of wheel drives for HXD1 and HXD3 series locomotives, the procedures corresponding to the models are as follows:

[0032]

[0033]

[0034] As shown in the table above:

[0035] Process A:

[0036] (1) Cleaning and inspection, (2) Disassembly of the axle box bearing, (3) Disassembly of the gearbox, (4) Disassembly of the motor, (5) Removal of the wheel, (6) Disassembly of the axle box, (7) Axle Cleaning, (8) Axle Repair and Unloading Tank, (9) Axle Magnetic Particle Inspection, (10) Axle Ultrasonic Inspection, (11) Axle Cleaning, (12) Axle Box Assembly, (13) Motor Assembly, (14) Gear Box Assembly, (15) pressure wheel, (16) back pressure, (17) axle box bearing assembly, (18) running-in test, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com