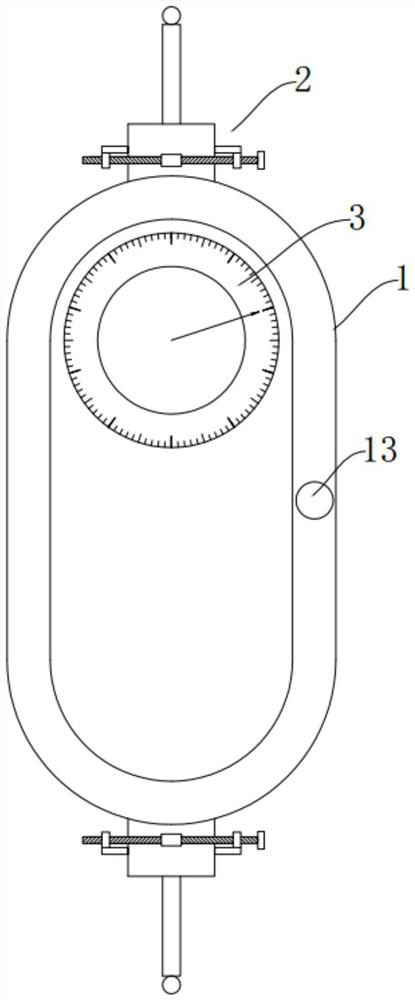

Inner gear ring rod spacing detection tool and use method thereof

A technology of rod spacing and inner gear ring, which is applied to the field of inspection tools for inner gear rod spacing, can solve the problems of time-consuming and laborious detection, insufficient measurement accuracy, insufficient fixation, etc., and achieves simplification of the measurement process, reduction of technical requirements, and suitable measurement. Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

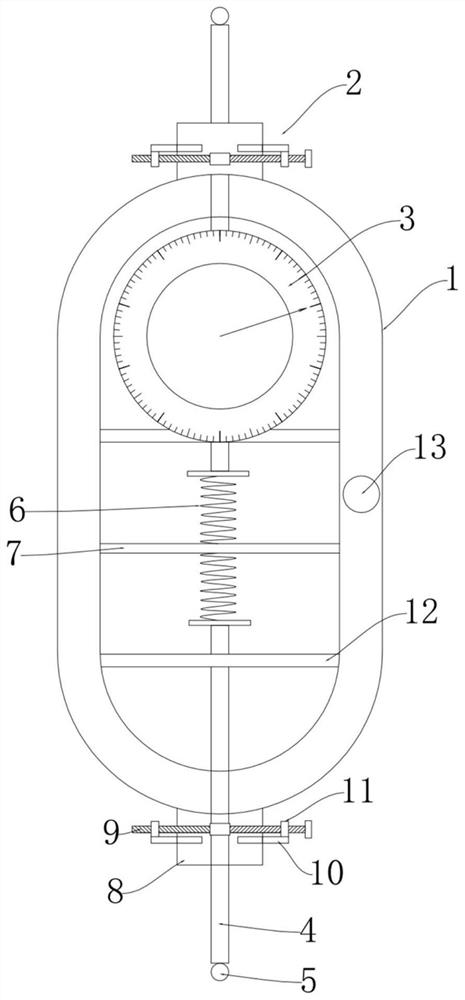

[0035] step one:

[0036] Measuring ball selection: install the measuring balls that match the internal gear to be tested on the telescopic testing heads on both sides of the device according to the rod spacing standard on the drawing;

[0037] Step two:

[0038] Gauge zero calibration:

[0039] Use a standard ring gauge to zero the dial indicator according to the rod spacing in the drawing;

[0040] Step three:

[0041] Fixture placement and leveling:

[0042] Place the device in the ring gear so that the measuring ball is against the tooth groove, and observe the level bubble to put the device in the right position;

[0043] Step four:

[0044] Fixing and reading of the gage:

[0045] By rotating the control screw rods on both sides of the inspection tool, the connecting nuts are driven to move relative to each other, so that the two-way fixed clamping rod clamps and fixes the telescopic detection head, and then the reading is performed.

[0046] Through the above met...

Embodiment 2

[0048] The staff sticks the measuring stick to both sides of the tooth alveolar, and then uses the measuring block or inner micrometer to measure the reading.

[0049] The measurement process by the above method is cumbersome, has high technical requirements for the staff, and cannot be applied to different types of internal gears, resulting in insufficient measurement accuracy and low efficiency.

[0050] During specific use, the staff installs the corresponding measuring ball 5 according to the detection of the internal gear, uses a standard ring gauge to zero the dial indicator 3 according to the rod spacing of the drawing, and then places the device in the ring gear to make the measuring ball 5 Under the action of the spring 7, it resists the tooth groove, and the device is placed in the right position through the level bubble 13, and then the connecting nut 11 is driven to move relatively by rotating the control screw 9, and the two-way fixed clamping rod 10 is driven to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com