Material disinfecting equipment

A technology of disinfection equipment and assembly, which is applied in the field of materials, can solve the problems of single function of material disinfection equipment, achieve the effects of convenient spraying of disinfectant, convenient power output, and prevention of dry running

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

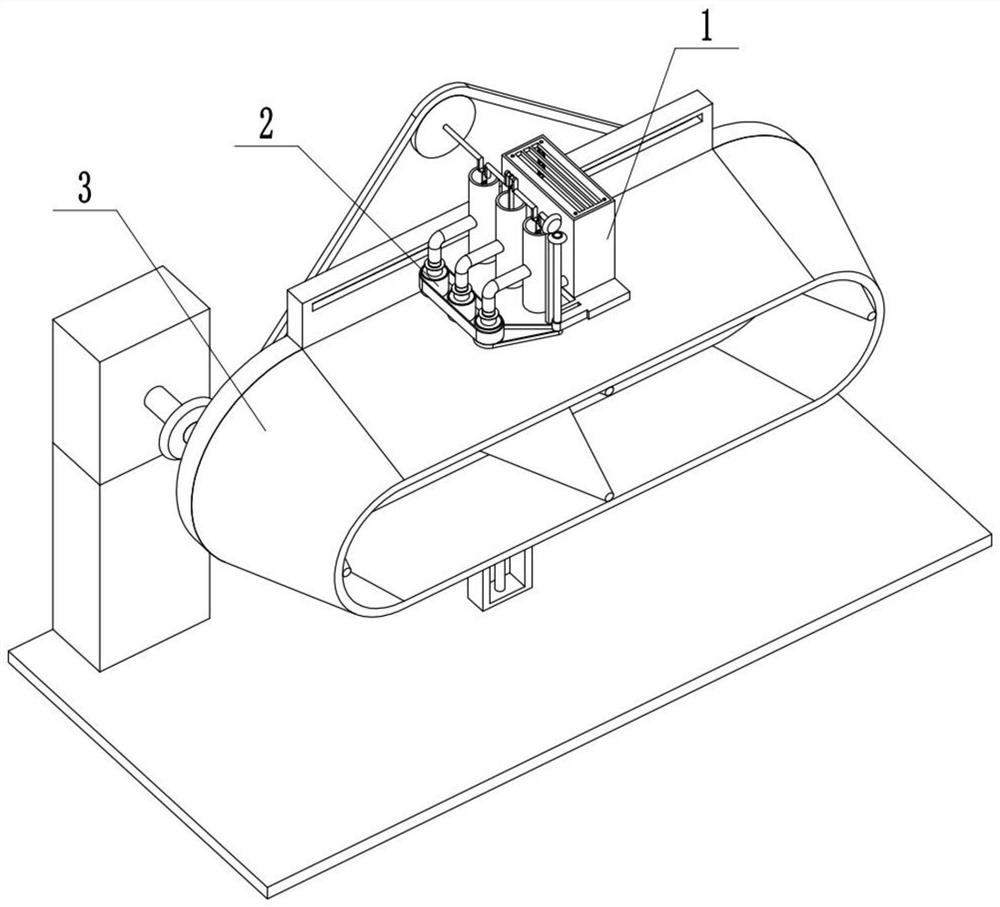

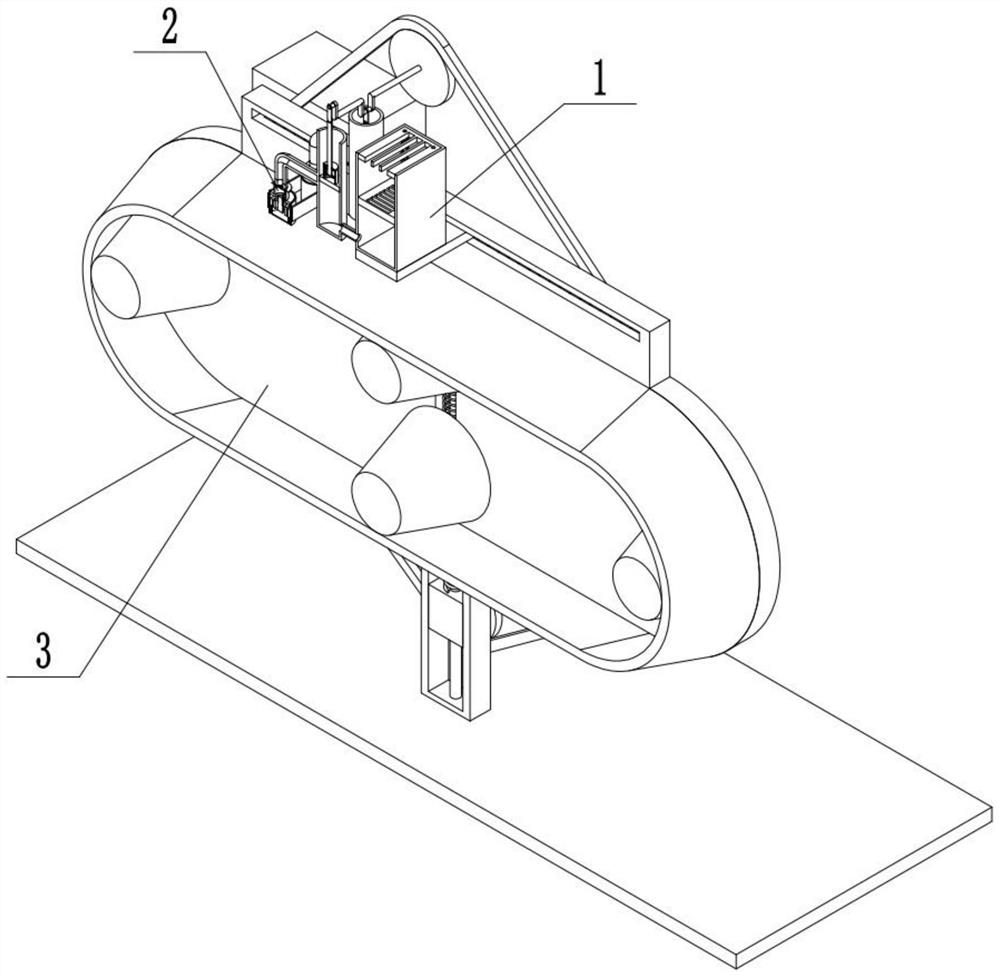

[0029] Combine below Figure 1-13 Describe this embodiment, a material disinfection equipment, including a liquid spray assembly 1, a spray head assembly 2, and a carrying assembly 3, characterized in that: the liquid spray assembly 1 is connected to the spray head assembly 2, and the spray head assembly 2 is connected to the carrier assembly 3.

specific Embodiment approach 2

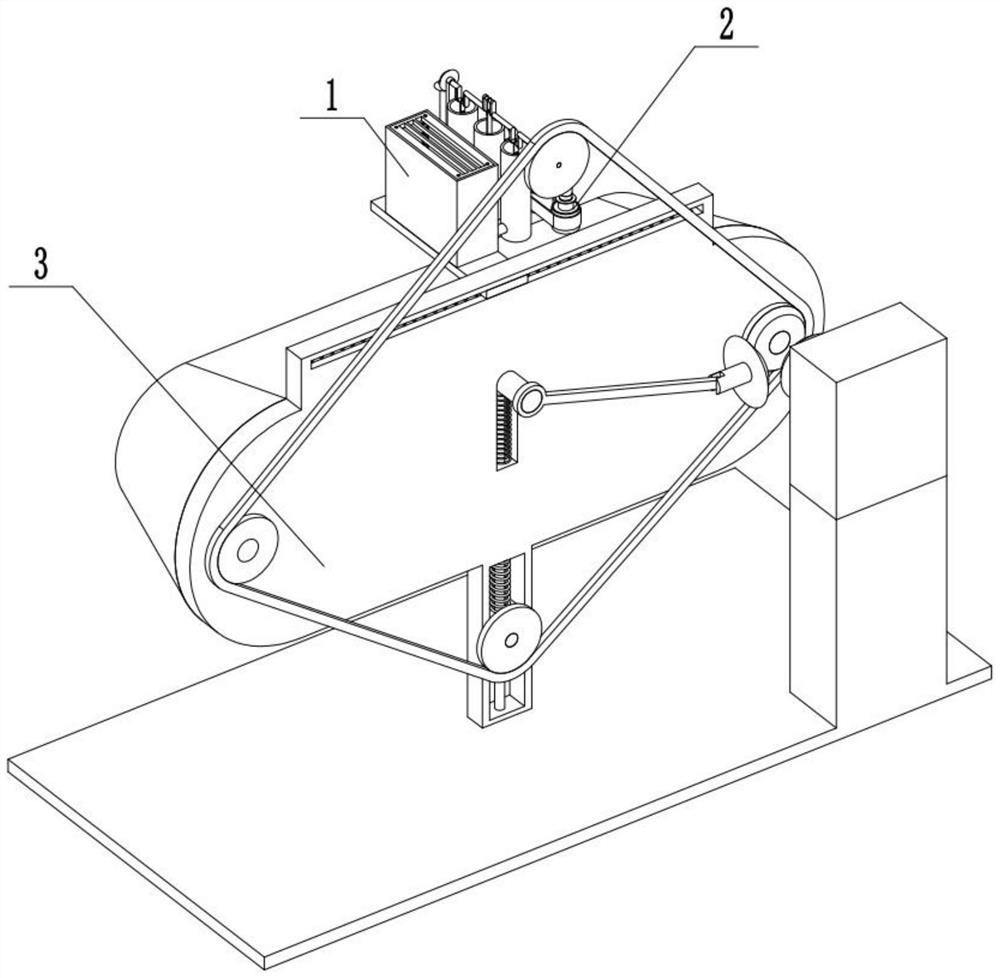

[0031] Combine below Figure 1-13Describe this embodiment, this embodiment will further explain Embodiment 1, the liquid spray assembly 1 includes a conduit 1-1, a piston sleeve 1-2, a crankshaft 1-3, a liquid storage outer frame 1-4, and a filter plate One 1-5, rectangular filter hole one 1-6, inner end sliding column one 1-7, inner end sliding column push spring one 1-8, crankshaft connecting rod 1-9, piston connecting rod 1-10, limit plate 1-11, piston plate 1-12, arc slot 1-13, arc bar 1-14, arc bar push spring 1-15, filter plate two 1-16, rectangular filter hole two 1-17 , Connecting pipe 1-18, the conduit 1-1 is fixedly connected and communicated with the piston casing 1-2, the connecting pipe 1-18 is fixedly connected to the piston casing 1-2 and the liquid storage outer frame 1-4, and the through pipe 1- 18 communicates with the piston sleeve 1-2 and the liquid storage outer frame 1-4, the inner end sliding column one 1-7 is fixedly connected with the liquid storage o...

specific Embodiment approach 3

[0033] Combine below Figure 1-13 Describe this embodiment. This embodiment will further explain Embodiment 1. The nozzle assembly 2 includes a rotatable sleeve 2-1, an axial limit plate 2-2, a connecting sleeve 2-3, and an adjustment plate 2. -4, connecting sleeve two 2-5, closing rod 2-6, wedge-shaped sleeve 2-7, through hole one 2-8, through hole two 2-9, inner end sliding column 2-10, inner end sleeve 2-11, the through hole 2-12 of the inner end casing, the spray hole 2-13, the axial limit plate 2-2 is connected with the rotatable sleeve 2-1 in rotation, and the connecting sleeve 2-3 is connected with the axial limit plate. The bit plate 2-2 is fixedly connected, the adjusting disc 2-4 is rotationally connected with the connecting sleeve 1 2-3, the adjusting disc 2-4 is rotationally connected with the connecting sleeve 2 2-5, and the adjusting disc 2-4 is connected with the closing rod 2- 6 Sliding fit connection, the closing rod 2-6 is rotationally connected with the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com