Novel rapid clamping device

A clamp and fast technology, applied in the direction of workpiece clamping devices, workbenches, manufacturing tools, etc., can solve the problems of low loading and unloading efficiency, loose bolts and nuts, and damage to objects, etc., to achieve firm and stable clamping, convenient and fast locking , the effect of preventing accidental falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the drawings:

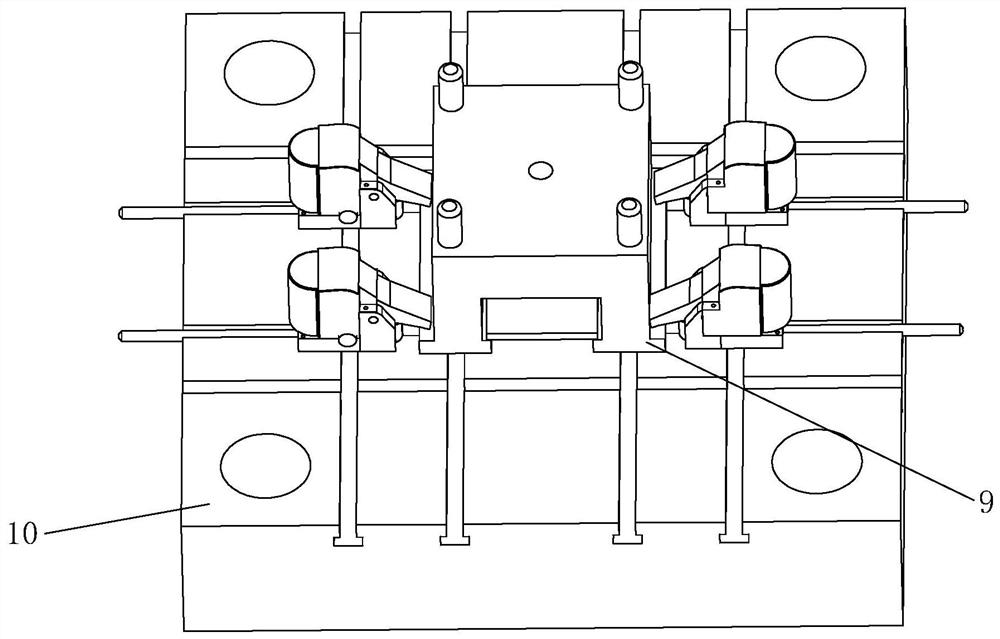

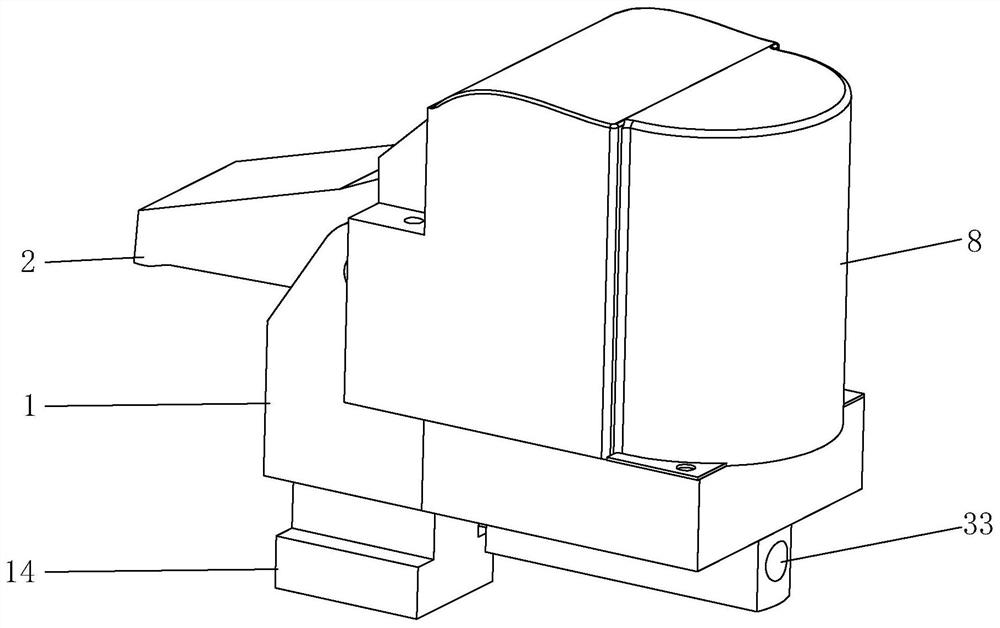

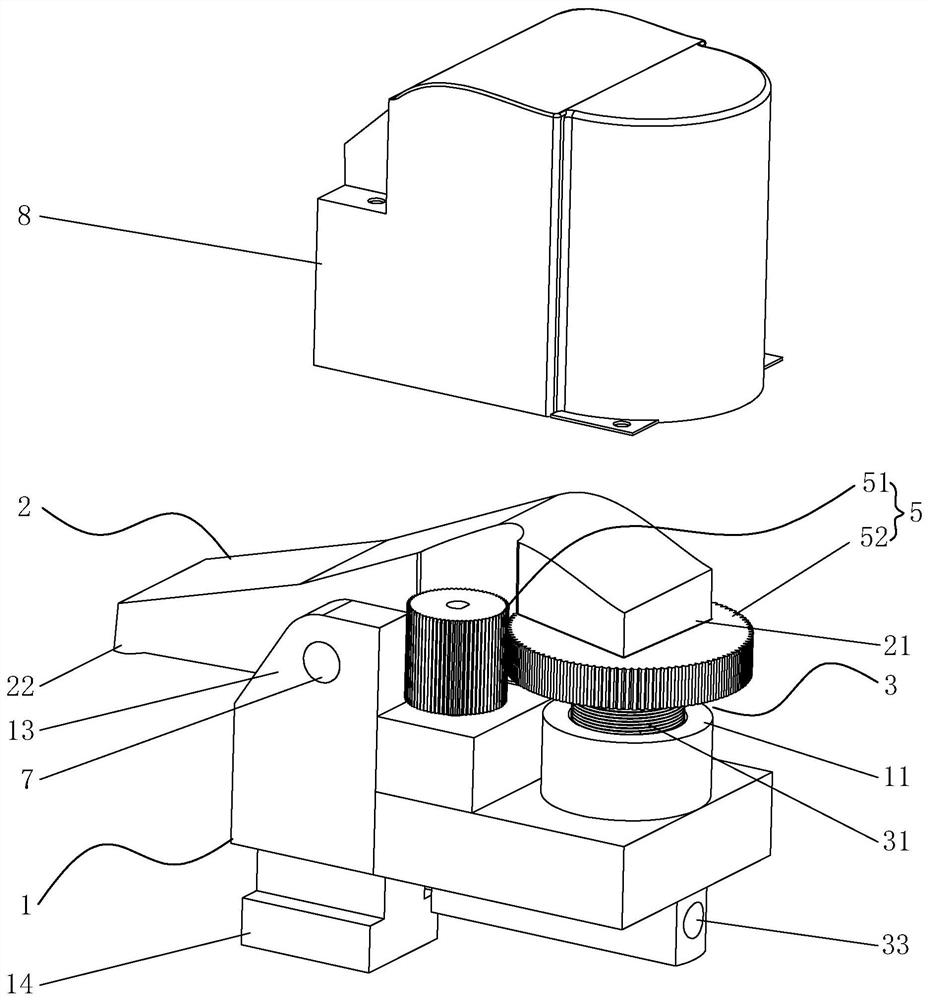

[0030] Such as Figure 1 to Figure 7 As shown, a new type of quick clamp includes a base 1, a clamping block 2 is hinged on the base 1, and the clamping block 2 is provided with a force end 21 on both sides of the hinge shaft 7 and presses the object against The clamping end 22 on the workbench 10 is provided with a power device 3 on the base 1 that can drive the force receiving end 21 to rotate the clamping block 2 around the hinge axis 4, and the base 1 is also provided with a clamping end 22 for clamping objects The rear locking power device 3 is a locking device 5 that keeps the power device 3 in a fixed position. A reset device 4 is provided between the clamping end 22 and the base 1 to press the clamping end 22 to reset the clamping block 2. When an object needs to be clamped, the power device 3 drives the force receiving end 21 of the clamping block 2, and the clamping end 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com