3D printing material spraying device

A 3D printing and material spraying technology, applied in the field of 3D printing, can solve the problems of unnatural connection at corners, defects in adaptive adjustment of transmission stability, affecting the appearance of products, etc., to ensure continuity and good material guidance. material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

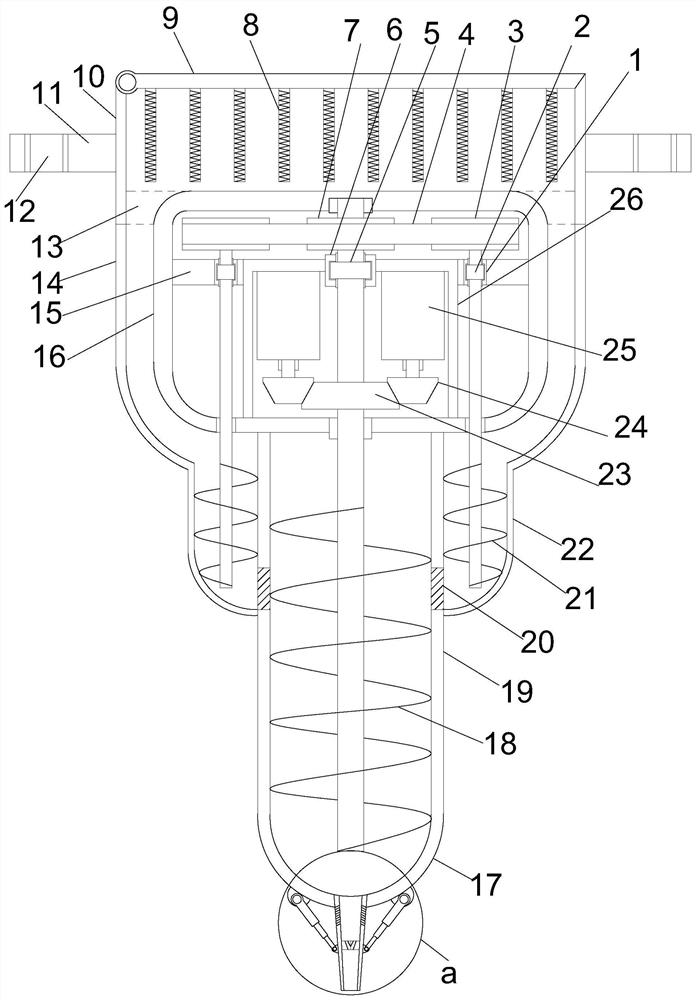

[0022] see Figure 1~3 , in an embodiment of the present invention, a 3D printing material spraying device includes a vertically arranged transmission installation cylinder 16, a support installation cylinder 10 is vertically provided on the upper end of the transmission installation cylinder 16, and a support installation cylinder 10 is symmetrically provided on the outside of the support installation cylinder 10. The mounting plate 11 and the supporting mounting plate 11 are provided with fixed mounting holes 12. The upper end of the supporting mounting cylinder 10 is equipped with a rotating cover plate 9 through a rotating shaft provided in the upper left corner. The lower side array of the rotating cover plate 9 is provided with several The electric auxiliary heating column 8, the middle position of the lower end of the transmission installation cylinder 16 is vertically provided with a main material installation cylinder 19, and the outer side of the upper half of the mai...

Embodiment 2

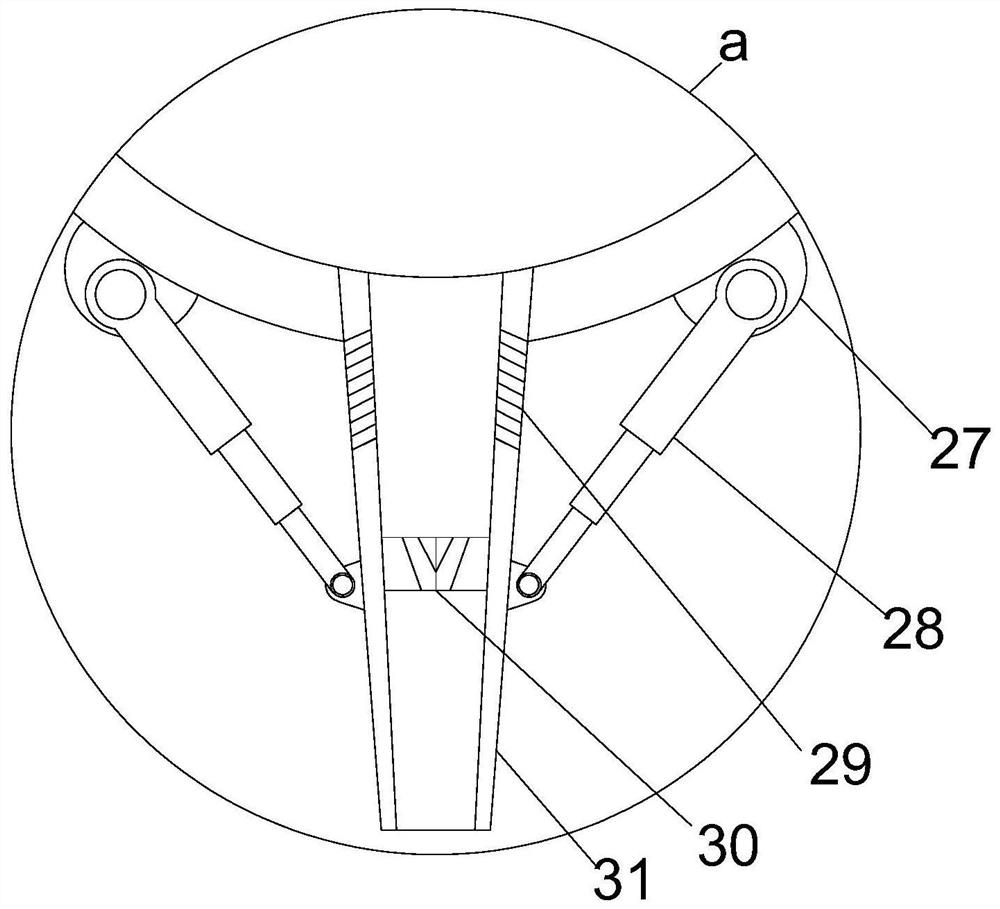

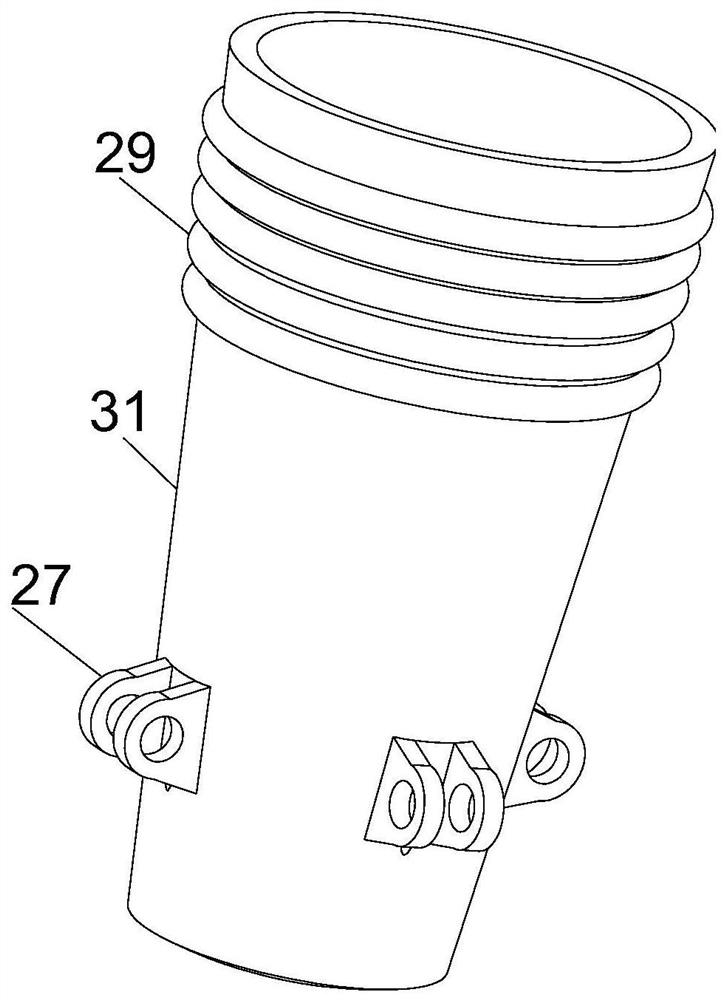

[0025] On the basis of Embodiment 1, by controlling the expansion and contraction of the swing telescopic column 28 and coordinating with the swing installation frame 27, the swing of the tapered discharge pipe is realized. Material operation, so that the device can change the angle of spraying material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com