Jacking construction method for large-span frame-structure bridge of combined I-shaped beam continuous reinforced line

A combined engineering and construction method technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., to achieve the effect of good line stability, easy operation and good continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

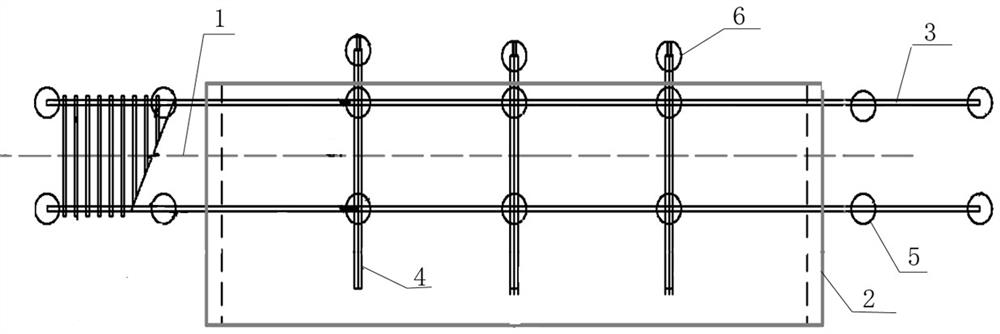

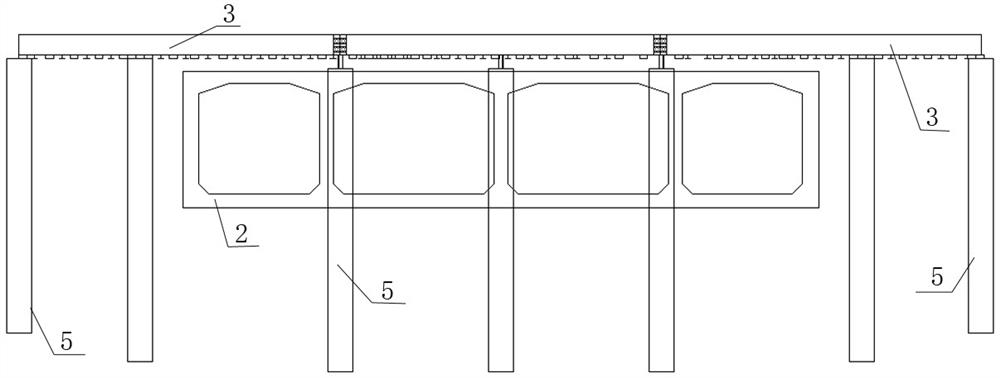

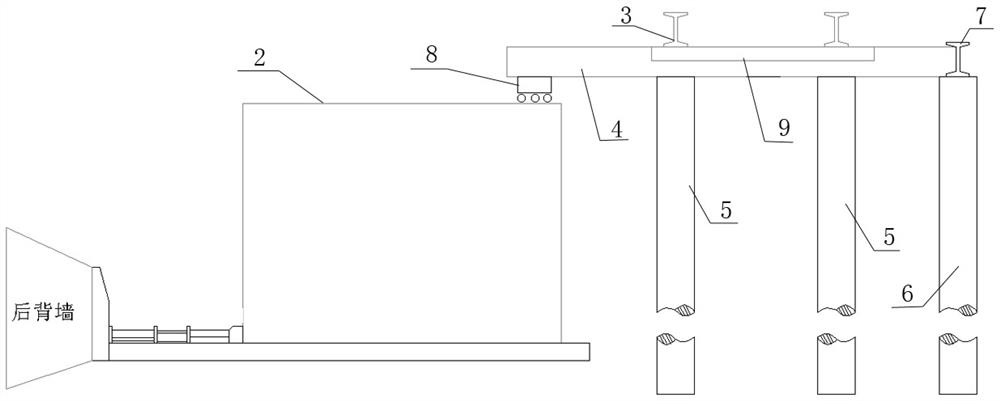

[0025] This long-span frame bridge is on the right side of the railway line ( figure 1 Below the China Railway Line) prefabrication. The combined overhead system of I100 construction beam and H70 horizontal lifting beam is used for reinforcement and overhead, and the overhead length is 3×16m. The I100 construction beams are set at a distance of 2.2m from the left and right sides of the line center, and each set of longitudinal beams is connected by H20 steel sleepers. Set up H70-type reinforced beams at the bottom of the rail on the two supporting piles in the horizontal direction. The left side of the line is extended to the pile crown beam in place to prevent the line from traversing during jacking. Two rows of steel bar pull rings are pre-embedded on the top plate of the box culvert, and the line and the bridge body are connected with chains and wire ropes during jacking to prevent the line from moving laterally. The train speed limit is 45km / h during the reinforcement o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com