Hydraulic power self-lifting anti-flood wall

A technology of self-lifting and flood control walls, applied in dikes, dams, water conservancy projects, etc., can solve the problems of increased flood control costs and manpower input, incalculable losses, and reduced reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

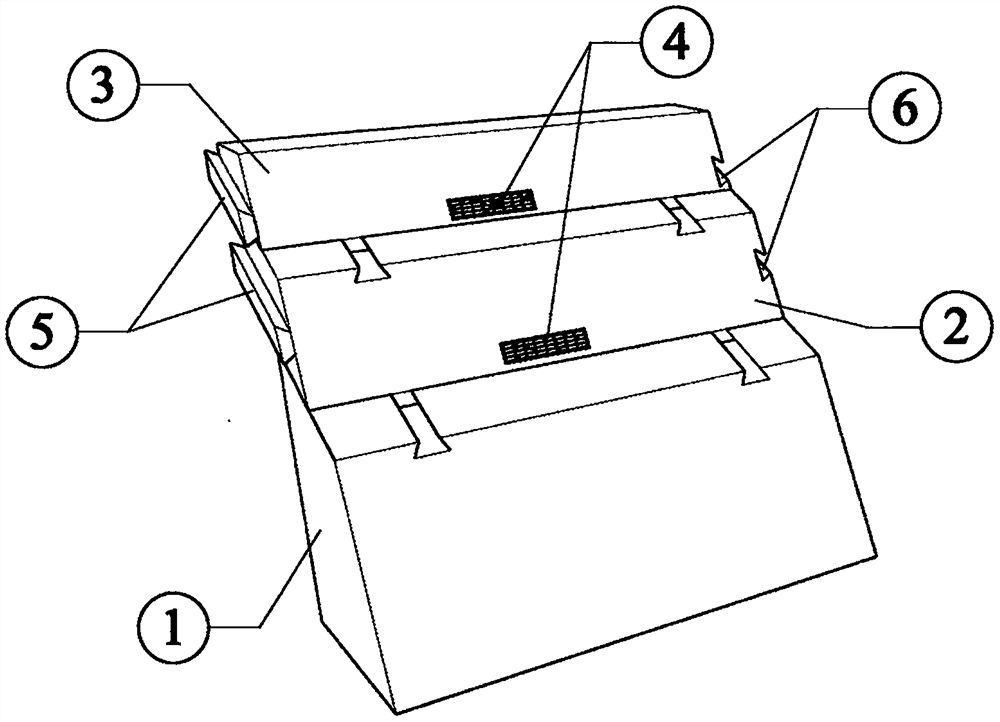

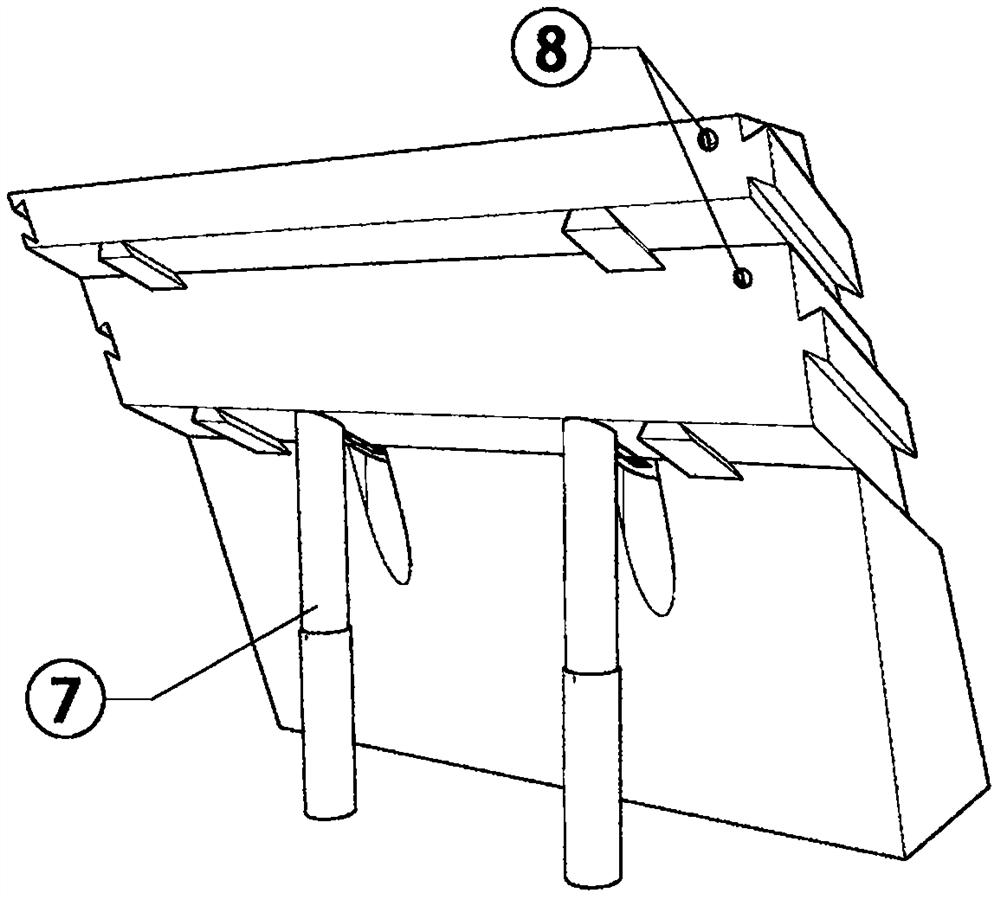

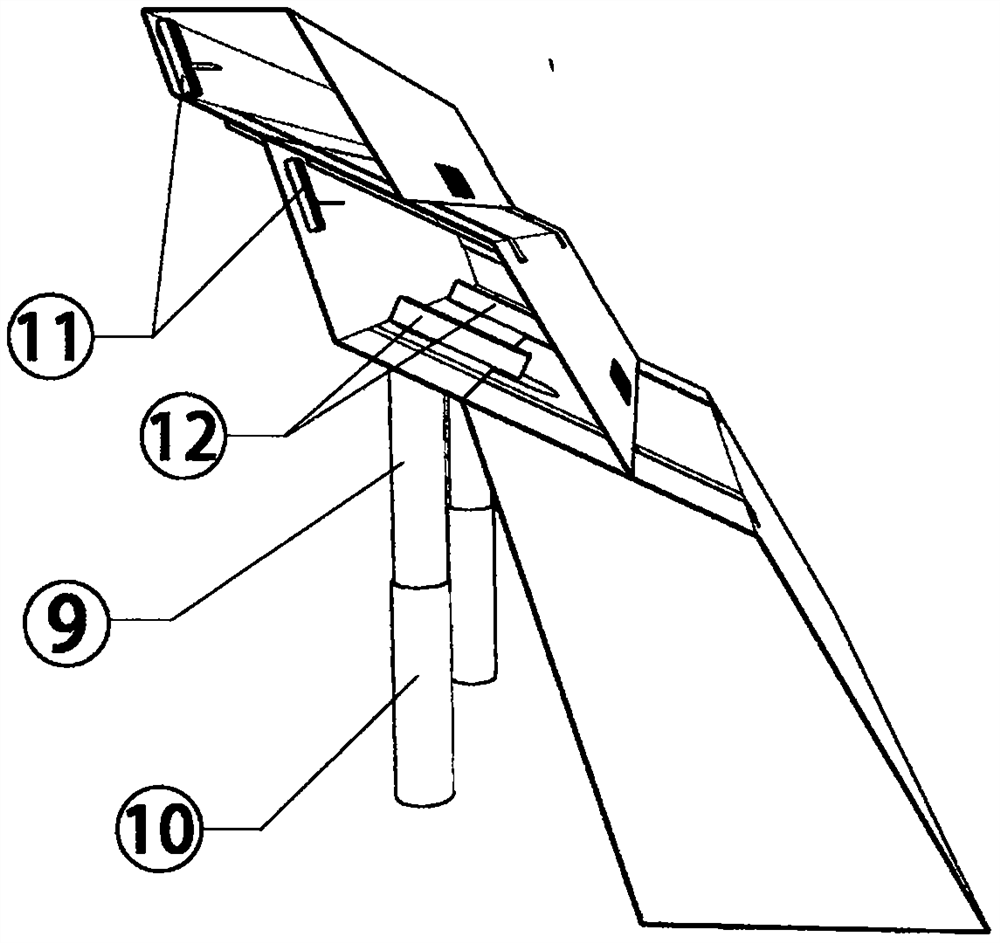

[0017] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A pedestal layer 1 of a hydraulic self-lifting flood control wall is fixed with a chute structure 6, and the chute structure 6 fits with the limit structure 5 fixed at the bottom of the lifting bottom 2, so that the lifting bottom 2 can Relatively sliding along the upper slope of the base layer 1 without falling off, the lifting bottom layer 2 is fixed with a chute structure 6, and the chute structure 6 fits with the limit structure 5 fixed at the bottom end of the lifting top layer 3, The lifting top layer 3 can slide relatively along the inclined surface of the lifting bottom layer 2 without falling off. An air hole automatic adjustment device 11 is installed, and a supporting contraction device 7 is installed at the bottom end of the lifting bottom layer 2 . The support contraction device 7 comprises a support trigger device 12, a support column I 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com