Integral special-shaped air duct for tunnel long-distance construction ventilation and construction method

An integral, long-distance technology, applied in the ventilation of mines/tunnels, tunnels, earthwork drilling and mining, etc., can solve the problems of reduced fan efficiency, long construction ventilation distance, poor auxiliary tunnel conditions, etc., to increase ventilation distance and reduce Effect of enlarging section and reducing engineering investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

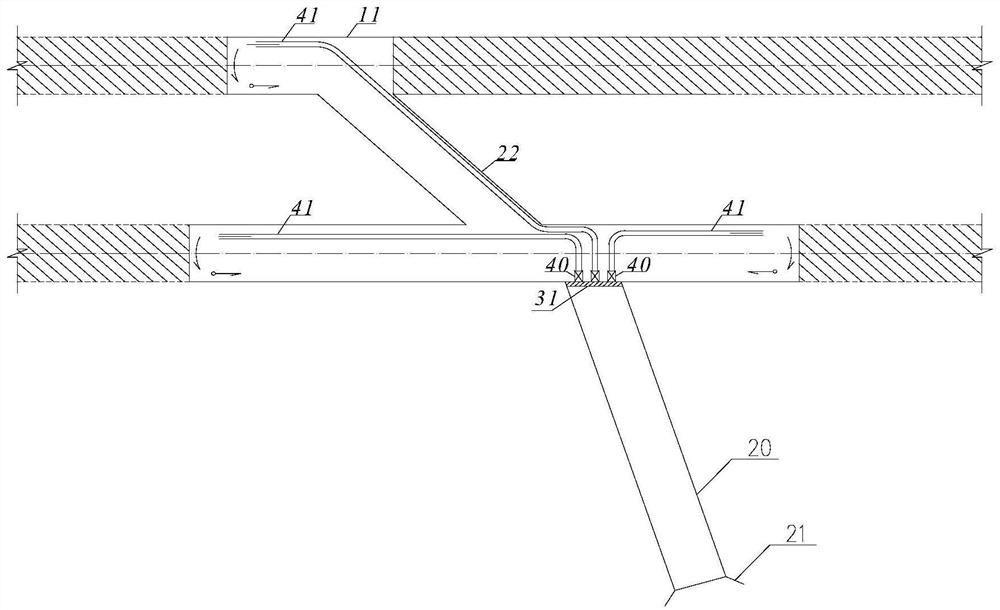

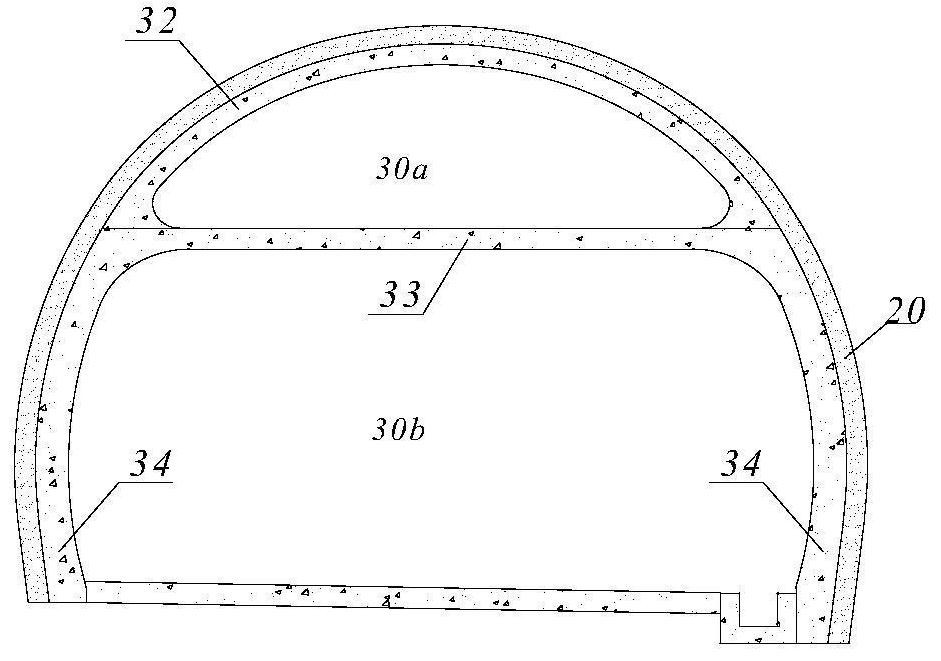

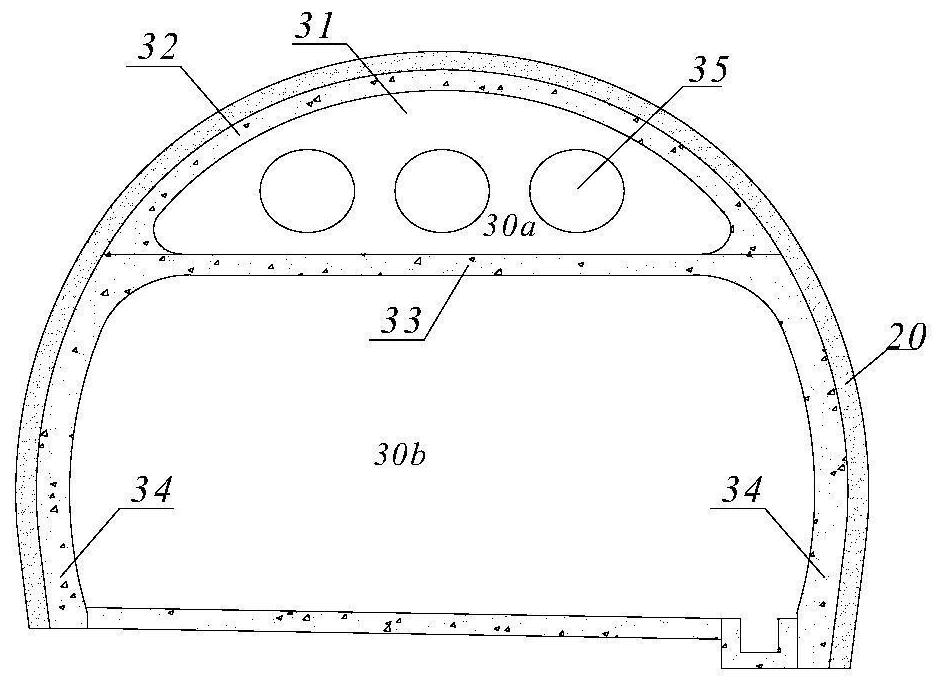

[0024] refer to Figure 1 to Figure 3 , 1 of the present invention is an integrated special-shaped air duct for long-distance tunnel construction ventilation, including a right-line main tunnel 10, a left-line main tunnel or parallel guide tunnel 11, and an auxiliary tunnel 20 connected to the right-line main tunnel 10 , the right-line positive hole 10, the left-line positive hole or parallel guide hole 11 are connected by a transverse passage 22. The auxiliary tunnel 20 is provided with an integral special-shaped air duct 30 molded by concrete. The integral special-shaped air duct 30 is formed by an arch portion 32 molded with the auxiliary tunnel 20, a side wall portion 34, and a section divided into The upper special-shaped air bin 30a, the lower channel 30b and the horizontal plate 33 constitute. That is, by setting the upper special-shaped air bin 30a on the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com