Adjustable automatic valve

An automatic valve and valve body technology, applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of heat group loss, resource waste, and inability to adjust in real time, and achieve the effect of reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to describe the technical content, structural features, goals and effects of the present invention in detail, the following examples are given to describe the embodiments in conjunction with the accompanying drawings.

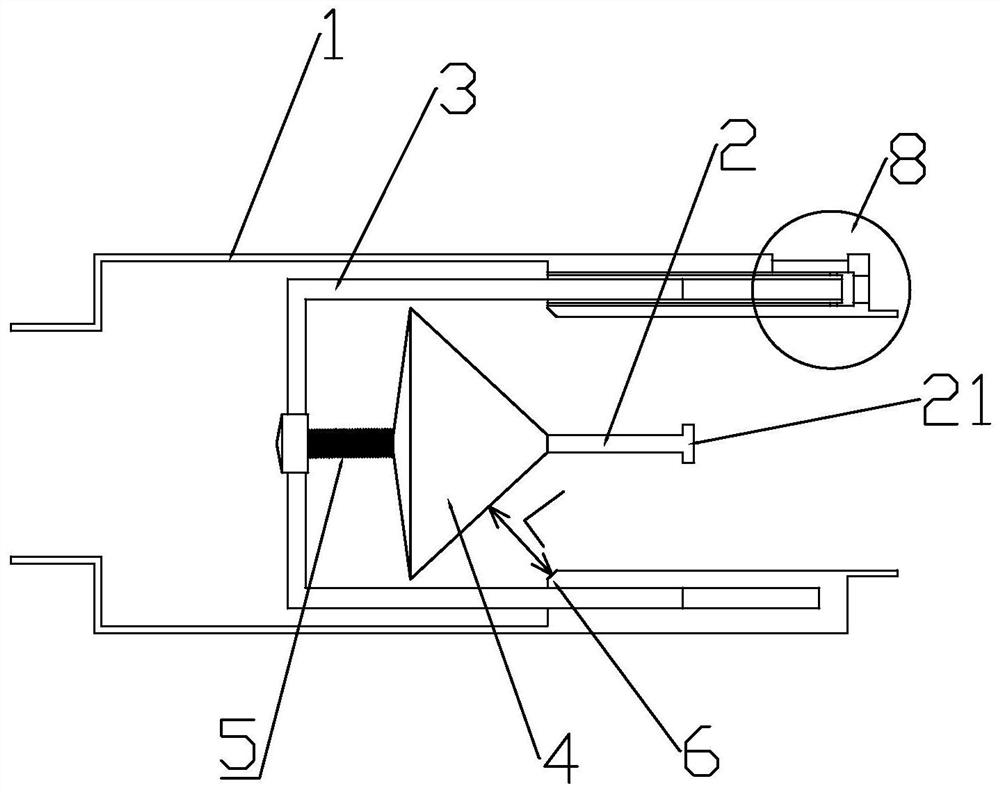

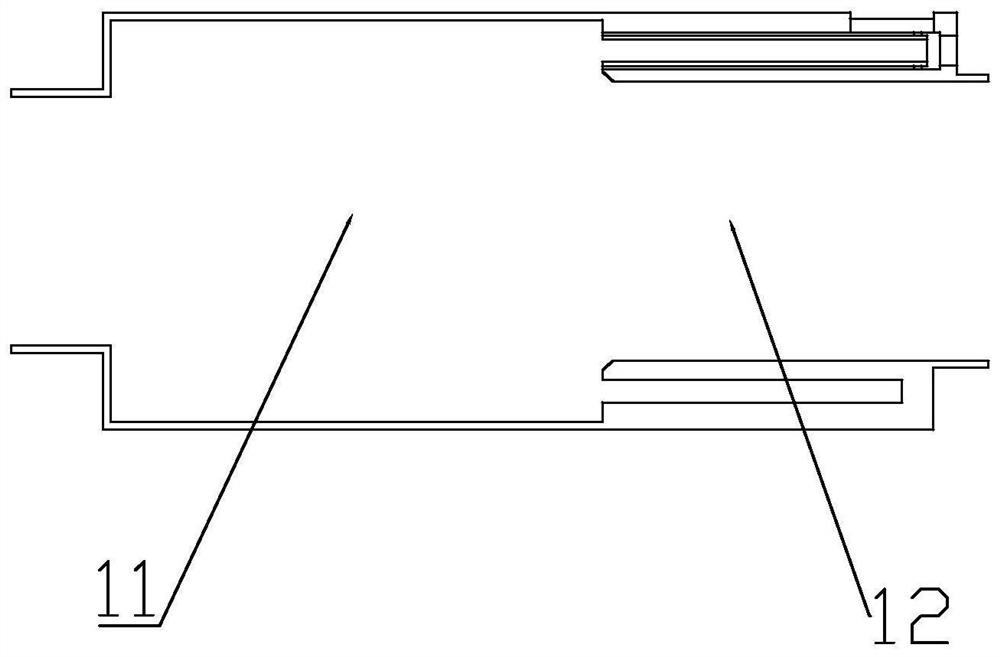

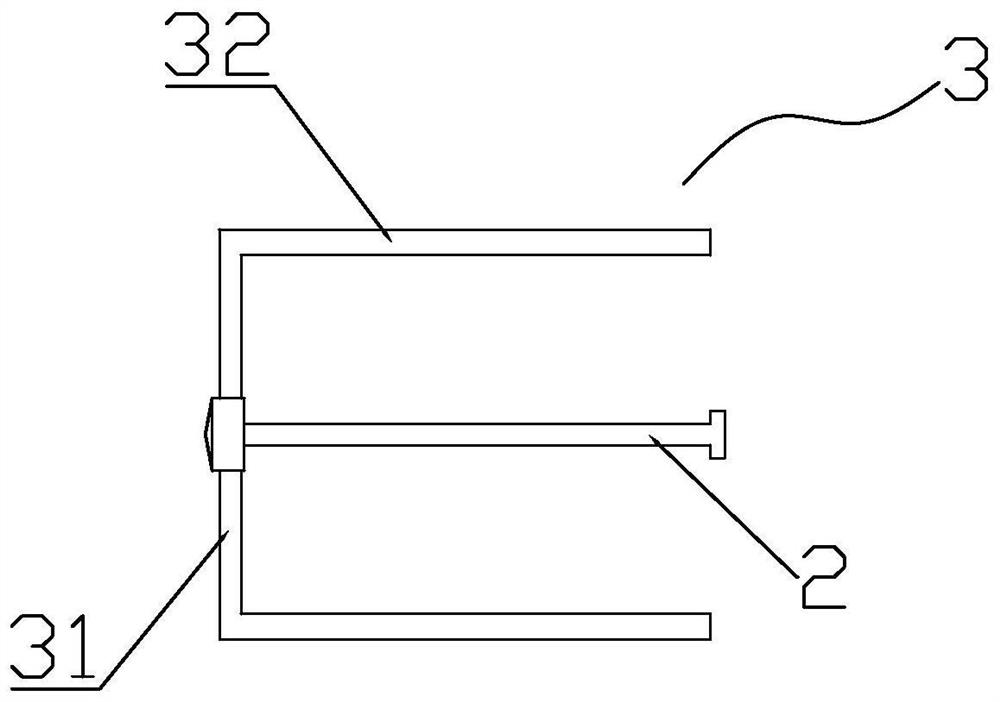

[0029] combine figure 1 and figure 2 , an adjustable automatic valve disclosed by the present invention, comprising a cylindrical valve body 1, a cavity is formed in the valve body 1, an axially arranged optical axis 2 is arranged in the valve body 1, and the optical axis 2 is set on the In the valve body 1, the optical axis 2 is fixedly connected with the bracket 3, and the bracket 3 is flexibly connected with the valve body 1, and the bracket 3 can drive the optical axis 2 to move along the axial direction of the valve body 1;

[0030] A valve head 4 is threaded on the optical axis 2, and a memory metal spring 5 is set on the optical axis 2 between the valve head 4 and the bracket 3; the inner wall of the valve body 1 is also provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com