Spinneret plate special-shaped hole size detection method

A technology for size detection and special-shaped holes, which is applied in the field of image processing and can solve the problems of poor versatility in the detection of spinneret hole size accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

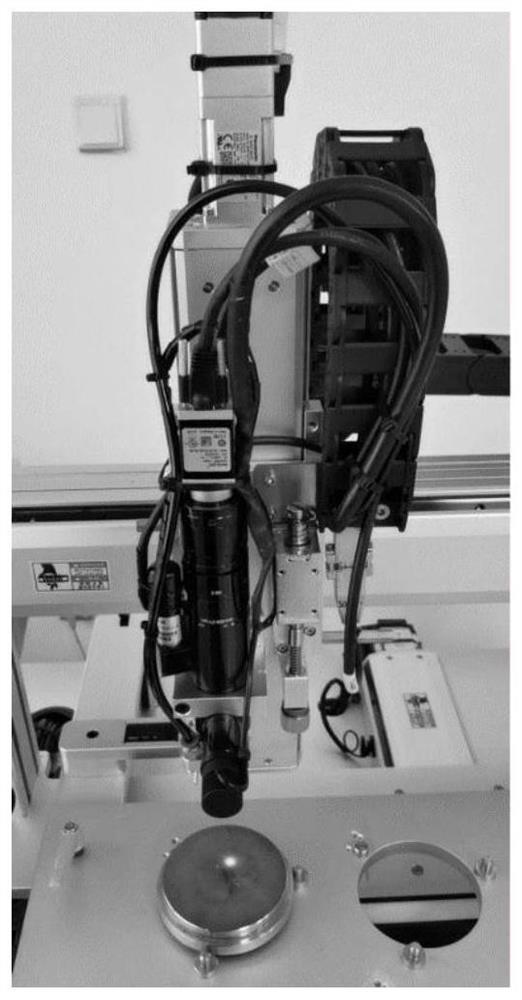

[0078] In this embodiment, according to the processing design of the outer contour of the spinneret hole, it is mainly based on the combination of line segments and arcs, and adopts a generalized non-rigid parametric matching model based on the combination of line segments and arcs to automatically process any type of spinneret. Modeling and detection of special-shaped holes in the plate to realize the universality of detection of special-shaped holes, including: image extraction, contour analysis and feature extraction through standard special-shaped hole images to automatically generate a general matching model; and then by rotating the contour of the hole image to be detected Angle correction, as well as global and local connected area pre-registration and parameterized model nonlinear registration based on least squares, optimize the position of feature control points, and optimally register the model contour reconstructed by the non-rigid matching model to the test object ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com