Unmanned aerial vehicle traction device for erecting wires

A technology of traction device and unmanned aerial vehicle, applied in the direction of overhead line/cable equipment, etc., can solve the problems of wire sheath wear, large wire swing, large wire drop accuracy error, etc., to achieve high work efficiency, reduce wind resistance, improve The effect of drop point accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

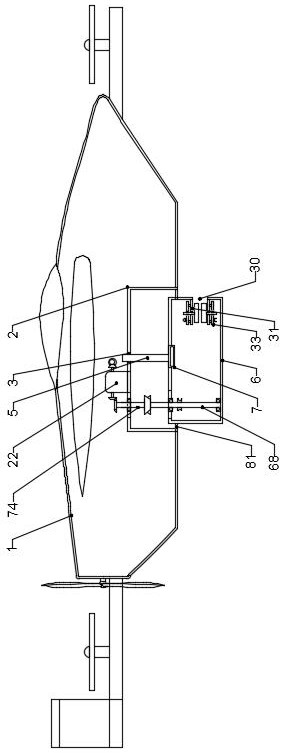

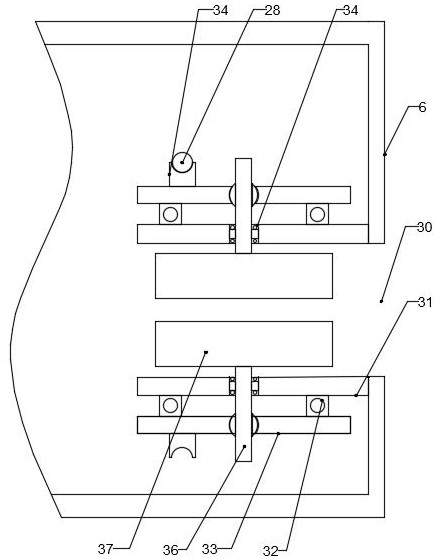

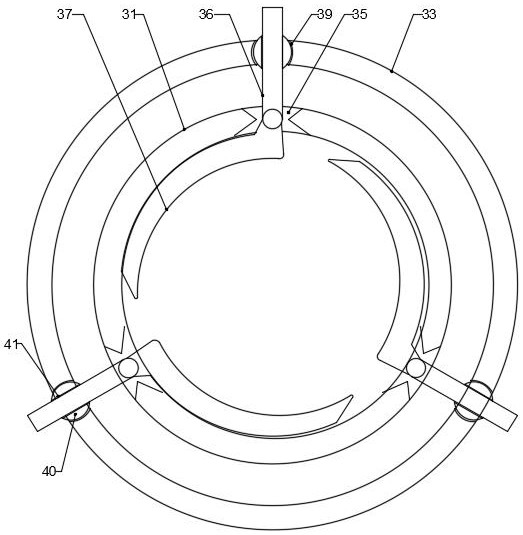

[0035] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-17As shown, a UAV traction device for erecting wires includes a composite wing UAV 1, the lower end of the composite wing UAV 1 is provided with a reciprocating lifting mechanism, and the lower end of the reciprocating lifting mechanism is provided with a clamping and releasing mechanism. There is a linkage transmission mechanism on one side of the release mechanism;

[0036] The reciprocating lifting mechanism includes a rectangular box 2 at the lower end of the compound wing UAV 1, a rectangular through hole 3 at the center of the upper surface of the rectangular box 2, a hollow tube 4 is installed on the inner ring of the rectangular through hole 1, and a hollow tube 4 is installed on the inner ring. There is a sliding rod 5, the lower end of the sliding rod 5 is equipped with an installation box 6, the upper surface of the installation box 6 is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com