Pipe packaging film folding and coating adhesive tape sealing device

A sealing device and packaging film technology, applied in packaging sealing/fastening, packaging, transportation packaging and other directions, can solve the problems of pipe breaking and detachment, high labor intensity, melting of packaging film, etc., so as to improve production efficiency and reduce human labor. , The effect of improving the quality of the pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

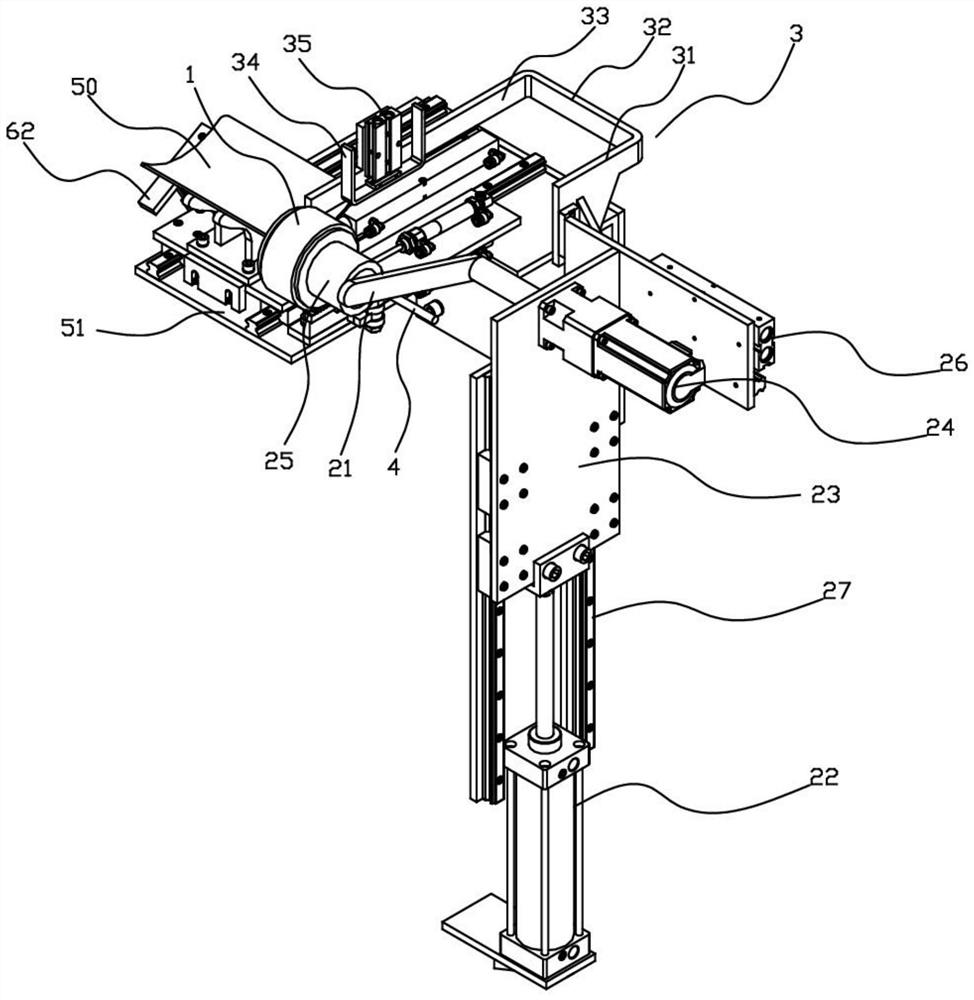

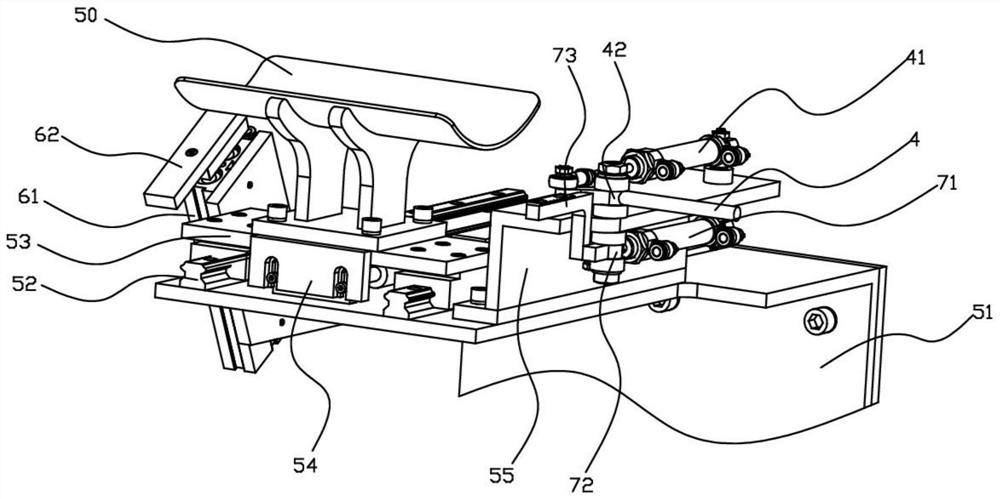

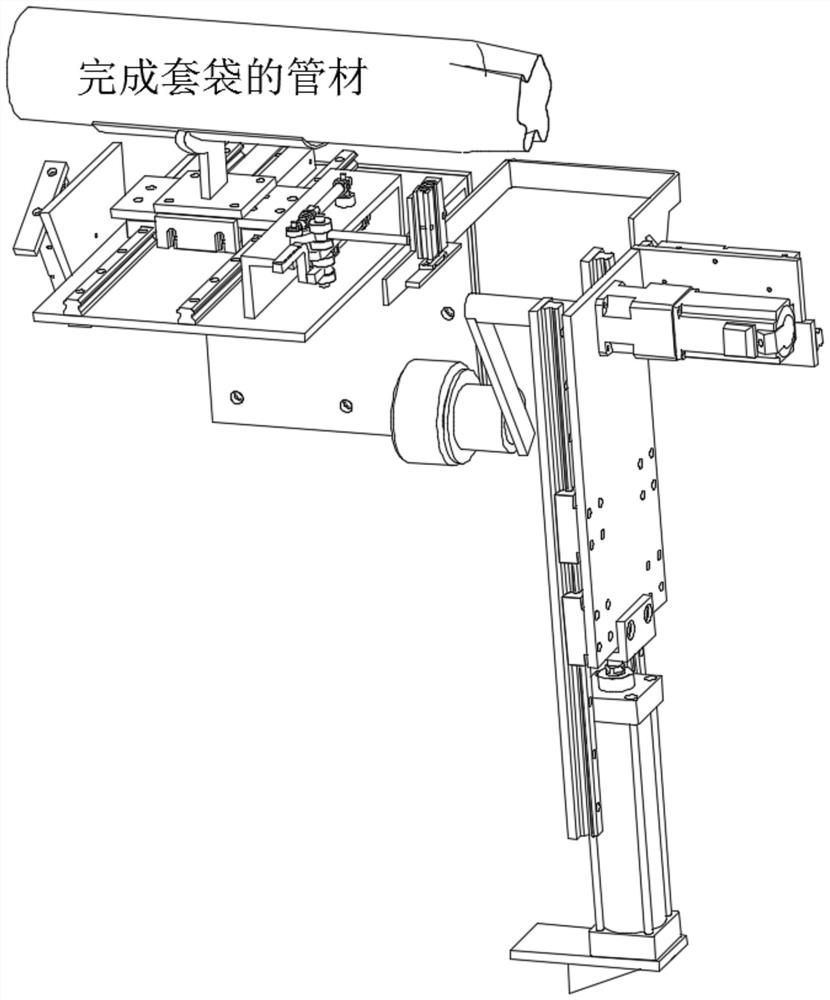

[0024] Such as figure 1 , 2 As shown, a pipe packaging film folding coating tape sealing device, the device can be divided into pipe supporting area and tape sealing area, including pipe supporting platform, longitudinal displacement mechanism, lateral displacement mechanism, tape 1, crank 21, first The driving device and the second driving device, wherein the pipe supporting platform is arranged in the pipe supporting area, and the other components are arranged in the tape sealing area. In this embodiment, the pipe supporting area is arranged on the left side of the tape sealing area.

[0025] In this embodiment, the longitudinal displacement mechanism includes a lifting cylinder 22 and a mounting plate 23. The end of the lifting cylinder 22 is connected to the mounting plate 23 to drive the mounting plate 23 to move longitudinally. In addition, in order to stabilize the stability of the mounting plate 23 movement, The both sides of mounting plate 23 are installed with the s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap