Damping reduction system suitable for transportation of rolled steel goods

A technology of cargo transportation and deceleration system, applied in the field of transportation, can solve the problems of difficulty in deceleration, low rolling friction resistance, etc., and achieve the effect of simple and effective use, avoiding collision or overturning damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings. As a limitation of the present invention.

[0049] As indicated in this application and claims, the terms "a", "an", "an" and / or "the" do not refer to the singular and include the plural unless the context clearly indicates an exception. At the same time, "left" and "right" in this application are only relative orientation concepts, and do not specifically refer to absolute directions.

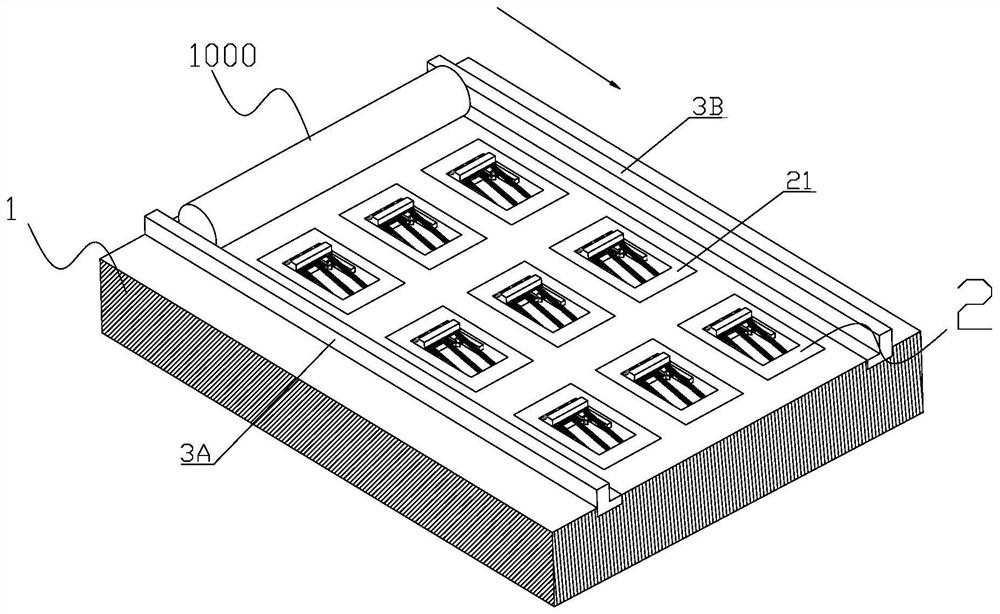

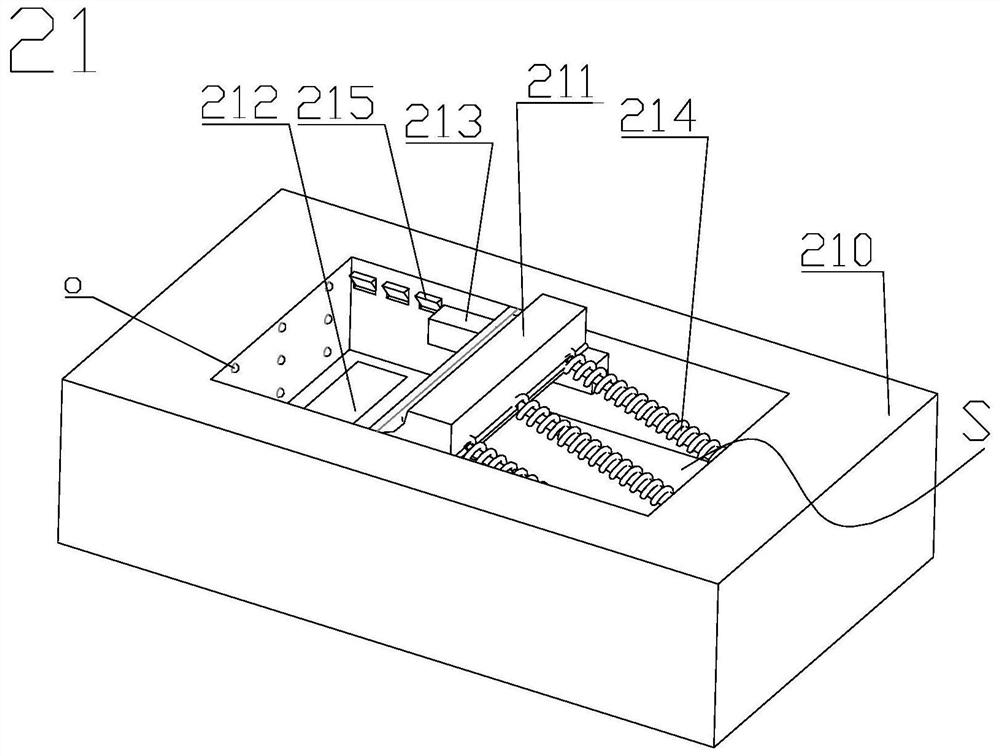

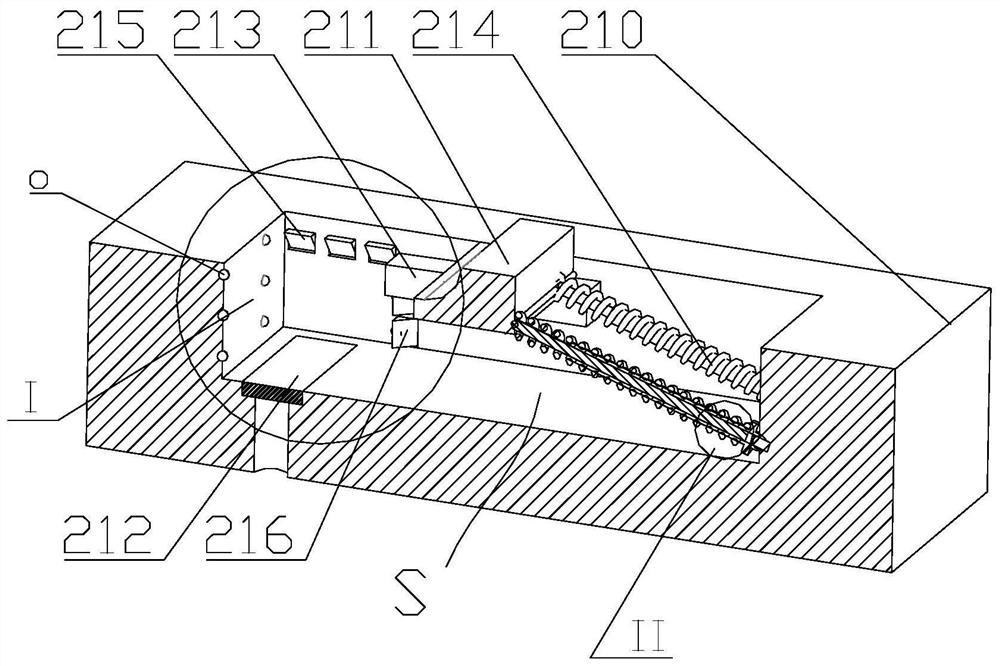

[0050] In some embodiments, such as figure 1 The damping deceleration system shown is suitable for the transportation of coiled steel goods, and is used to decelerate from the initial speed V0 to the set speed V1 when the item 1000 to be transported moves from left to right on the surface of the roadbed 1, and the item 1000 to be transported is preferably It is a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com