A quantum dot-rare earth long afterglow composite luminescent material and its preparation method and application

A technology of long afterglow luminescence and long afterglow materials, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of limiting the degree of freedom of luminescence regulation and the inability to realize narrow-band emission, and achieves simple synthesis methods, easy large-scale preparation, and easy The effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

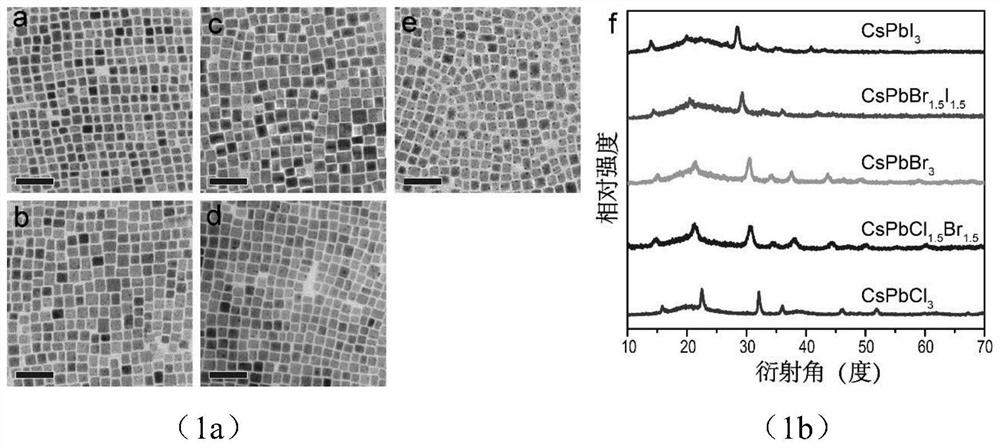

[0049] Preparation Example 1 CsPbCl 3 Preparation of perovskite quantum dots

[0050] Weigh 0.5mmol lead acetate and 0.1mmol cesium carbonate, then add 1mL oleic acid, 1mL oleylamine, 1mL tri-n-octylphosphine and 10mL octadecene, heat to 120°C with nitrogen gas and keep it warm for 10 minutes to form a transparent solution A, then Raise the temperature to 180°C; quickly inject 124 μL of hydrochloric acid into solution A, keep warm for 10 seconds, and quickly cool it in an ice bath (cooling rate is about 10-15°C / second) to room temperature; first centrifuge and then use 10mL cyclohexane and 10mL acetone Wash once, and disperse the precipitate in 30 mL cyclohexane to obtain CsPbCl 3 Perovskite quantum dots.

preparation example 2

[0051] Preparation Example 2 CsPbCl 1.5 Br 1.5 Preparation of perovskite quantum dots

[0052] Weigh 0.5mmol lead acetate and 0.05mmol cesium carbonate, then add 0.5mL oleic acid, 0.5mL oleylamine and 6mL octadecene, heat to 120°C with nitrogen gas and keep it warm for 30 minutes to form a transparent solution A, then heat up to 190°C; Quickly inject 62 μL of hydrochloric acid and 87 μL of hydrogen bromide into solution A, keep warm for 5 seconds, and quickly cool to room temperature in an ice-water bath; centrifuge and then wash once with 5 mL of cyclohexane and 5 mL of acetone, and disperse the precipitate in a 30 mL ring In hexane, CsPbCl is obtained 1.5 Br 1.5 Perovskite quantum dots.

preparation example 3

[0053] Preparation Example 3 CsPbBr 3 Preparation of perovskite quantum dots

[0054] Weigh 0.5mmol lead acetate and 0.08mmol cesium carbonate, then add 1.5mL oleic acid, 1.5mL oleylamine and 8mL octadecene, heat to 120°C with nitrogen gas and keep it warm for 30 minutes to form a transparent solution A, then heat up to 170°C; Quickly inject 173 μL of hydrogen bromide into solution A, keep warm for 10 seconds, and quickly cool in an ice bath (cooling rate is about 10-15°C / second) to room temperature; first centrifuge and then wash once with 5mL cyclohexane and 5mL acetone , and the precipitate was dispersed in 30 mL cyclohexane to give C s PbBr 3 Perovskite quantum dots.

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap