Method for improving lighting effect and stability of light-storing ceramics simultaneously

A stable and ceramic technology, applied in the direction of alkaline earth metal titanate, titanate, etc., can solve the problems of overall transmittance reduction, excitation light fluorescence scattering loss, etc., to improve barrenness, eliminate birefringence, and improve Effect of fluorescence output intensity and duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The specific preparation method includes the following steps:

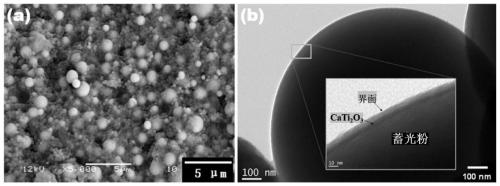

[0035] (1) Weigh calcium nitrate and citric acid according to the mass ratio of 10:0.5, and dissolve them in absolute ethanol, stir magnetically for 20 minutes at a speed of 150r / min to form an ethanol solution of calcium; weigh tetra-n-butyl titanate and Dissolve in anhydrous ethanol, magnetically stir for 20min at a speed of 150r / min, and add glacial acetic acid dropwise during the stirring process to form a titanium precursor liquid; under stirring conditions, add the calcium alcohol solution to the titanium precursor liquid, and add the dispersion Oleic acid, and then add pure water, light storage powder (select Sr 4 Al 14 O 25 :Eu, Dy, particle size of 500 microns), continue to stir for 1h to obtain phosphor-calcium titanate gel;

[0036] (2) Heating the light-storing powder-calcium titanate gel obtained in step (1) at 80°C for 2 hours to obtain a calcium titanate-coated light-storing powder dry gel, crush ...

Embodiment 2

[0045] The specific preparation method includes the following steps:

[0046] (1) Weigh calcium nitrate and citric acid according to the mass ratio of 10:1.5, and dissolve them in absolute ethanol, magnetically stir for 60 min, rotate speed 300r / min, and form a calcium ethanol solution; weigh tetra-n-butyl titanate and Dissolve in anhydrous ethanol, magnetically stir for 60min, rotate at 300r / min, and add glacial acetic acid dropwise during the stirring process to form a titanium precursor liquid; under stirring conditions, add the calcium ethanol solution to the titanium precursor liquid and add dispersion Oleic acid, and then add pure water, light storage powder (select Sr 4 Al 14 O 25 :Eu, Dy, particle size of 500 microns), continue to stir for 4h to obtain phosphor-calcium titanate gel;

[0047] (2) Heating the luminescent powder-calcium titanate gel obtained in step (1) at 150°C for 8 hours to obtain a calcium titanate-coated luminescent powder xerogel, crushing, and passing t...

Embodiment 3

[0052] The specific preparation method includes the following steps:

[0053] (1) Weigh calcium nitrate and citric acid according to a mass ratio of 10:1, and dissolve them in absolute ethanol, stir magnetically for 30 minutes at a speed of 200r / min to form an ethanol solution of calcium; weigh tetra-n-butyl titanate and Dissolve in anhydrous ethanol, magnetically stir for 40min, rotate at 200r / min, and add glacial acetic acid dropwise during the stirring process to form a titanium precursor liquid; under stirring conditions, add the calcium alcohol solution to the titanium precursor liquid and add dispersion Oleic acid, and then add pure water, light storage powder (select Sr 4 Al 14 O 25 :Eu, Dy, particle size of 10 microns), continue to stir for 2h to obtain phosphor-calcium titanate gel;

[0054] (2) Heating the luminescent powder-calcium titanate gel obtained in step (1) at 150°C for 8 hours to obtain a calcium titanate-coated luminescent powder xerogel, crushing, and passing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap