Forward design and calculation method of sprag clutch structure

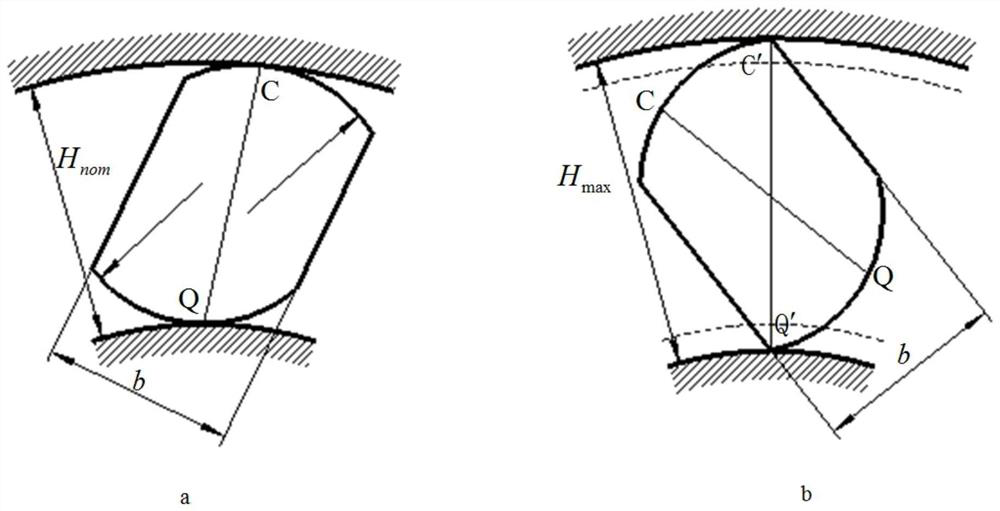

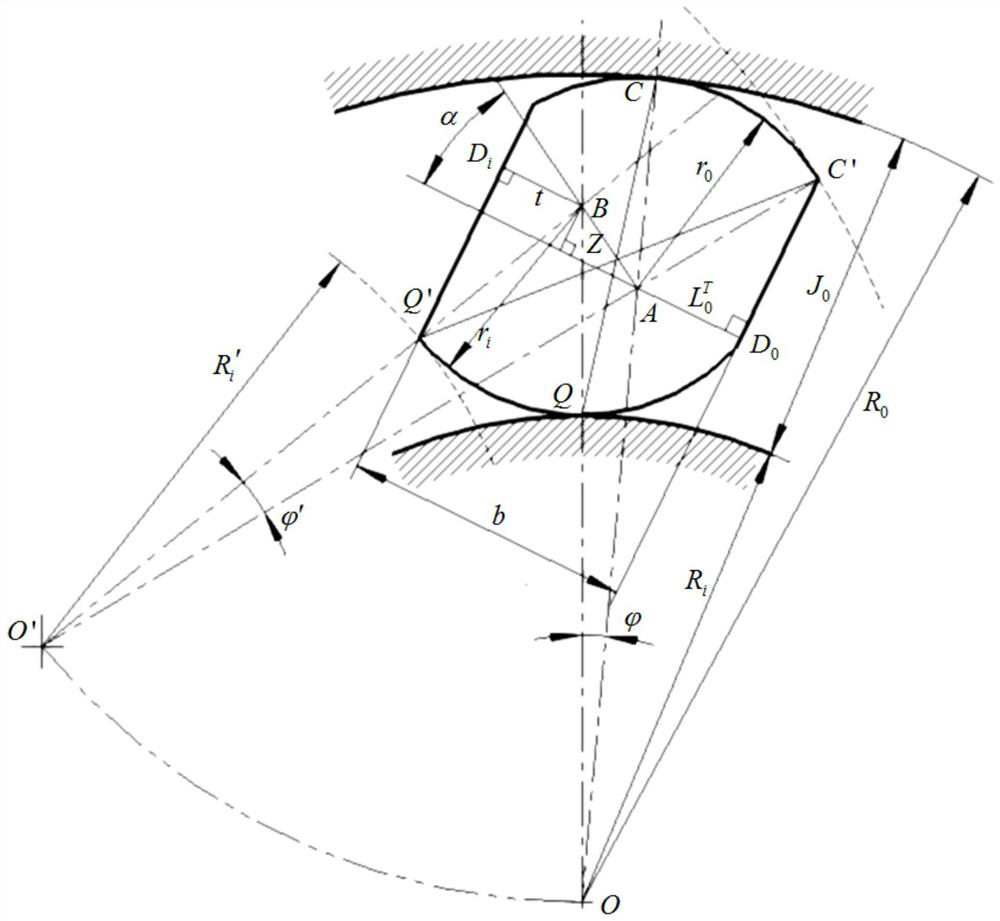

A clutch and sprag technology, applied in the design field of sprag type overrunning clutch, can solve the problems of specific position of wedge width, design method and basis not given, etc., to achieve overall performance improvement and effective lift optimization , The effect of the turning torque increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Embodiment 1: For specification J 0 = 6.300 standard wedge for calculation and optimization, given 5 basic parameters, according to the above method and calculation formula II-VII, the important positioning parameter L of wedge width b is obtained 0 = 1.7529. At this time, the maximum lift is S R =0.3067;

Embodiment 2

[0075] Embodiment 2: For specification J 0 =8.331 standard wedge for calculation and optimization, given 5 basic parameters, according to the above method and calculation formula II-VII, the important positioning parameter L of wedge width b is obtained 0 =2.2817. At this time, the maximum lift is S R =0.4490;

Embodiment 3

[0076] Embodiment 3: for specification J 0 =9.500 standard wedge for calculation and optimization, given 5 basic parameters, according to the above method and calculation formula II-VII, the important positioning parameter L of wedge width b is obtained 0 =2.3706. At this time, the maximum lift is S R =0.4891;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com