A combined blower-type high-efficiency shoe-drying rack

A blowing-type, high-efficiency technology, applied to hangers, clothing, applications, etc., can solve the problems of low drying efficiency, potential safety hazards, and easy fires, and achieve the effect of being easy to carry, safe and reliable to use, and avoiding the growth of mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The content of the present invention will be further elaborated below in conjunction with the drawings and embodiments of the description.

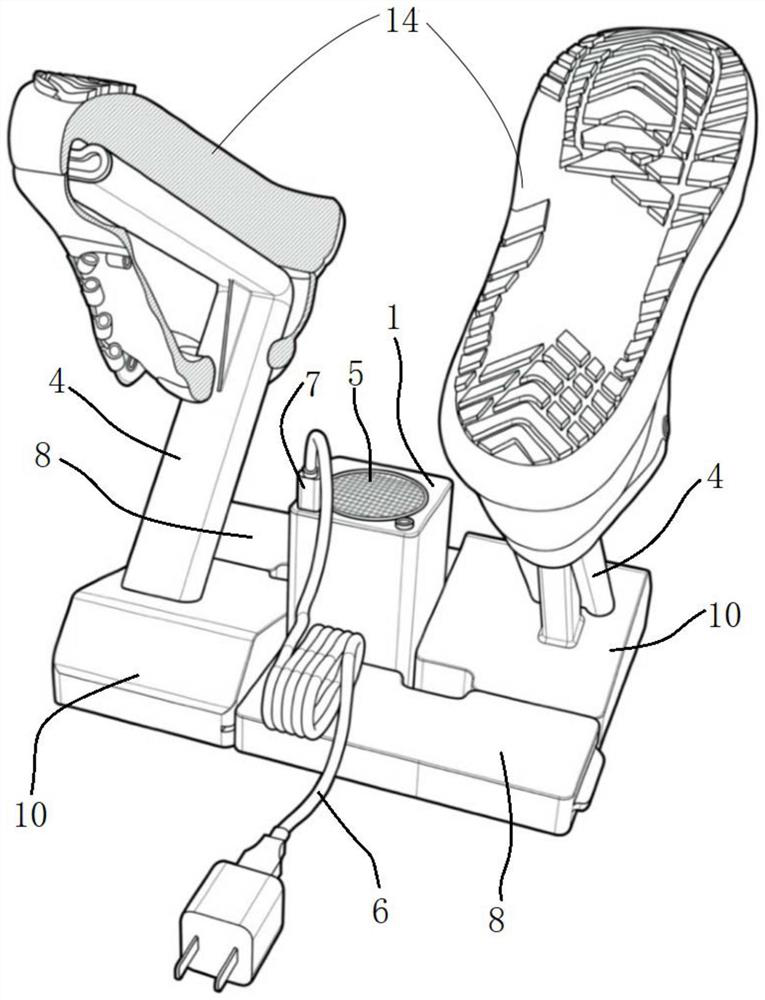

[0029] Such as Figure 1 to Figure 7 As shown, a combined blowing type high-efficiency shoe drying rack includes an air pump box 1, a diversion box 8 symmetrically arranged on both sides of the air pump box and connected to the air pump box, two bases 10 respectively connected to the diversion box, installed on the base Tubular shoe rack.

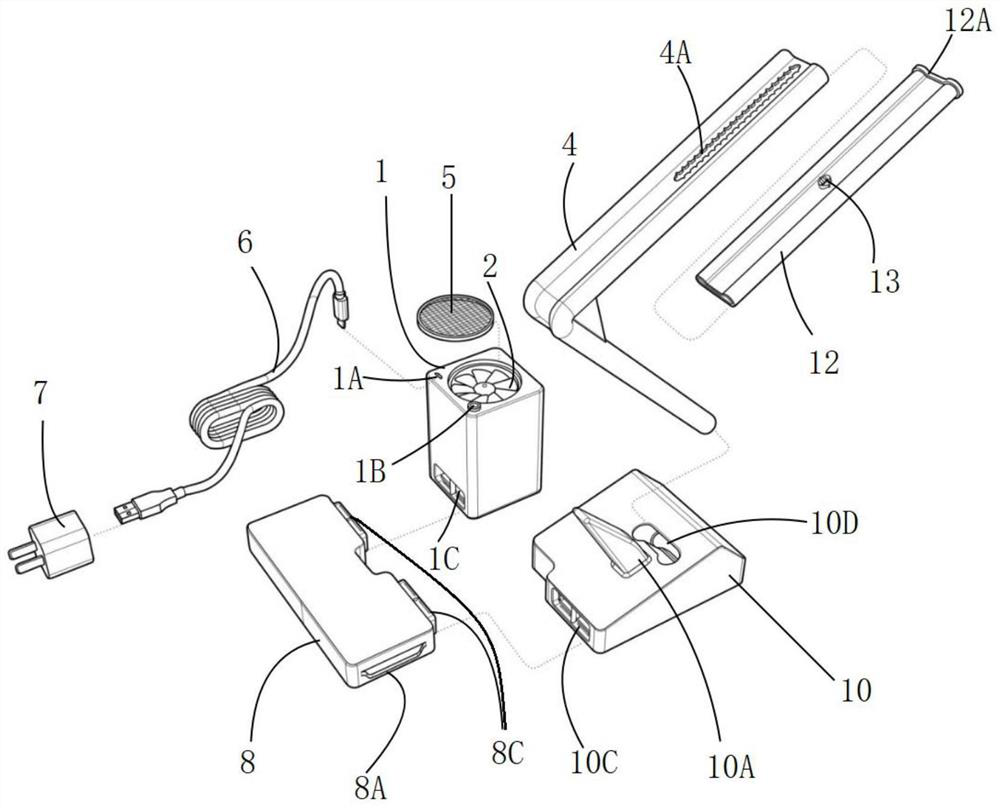

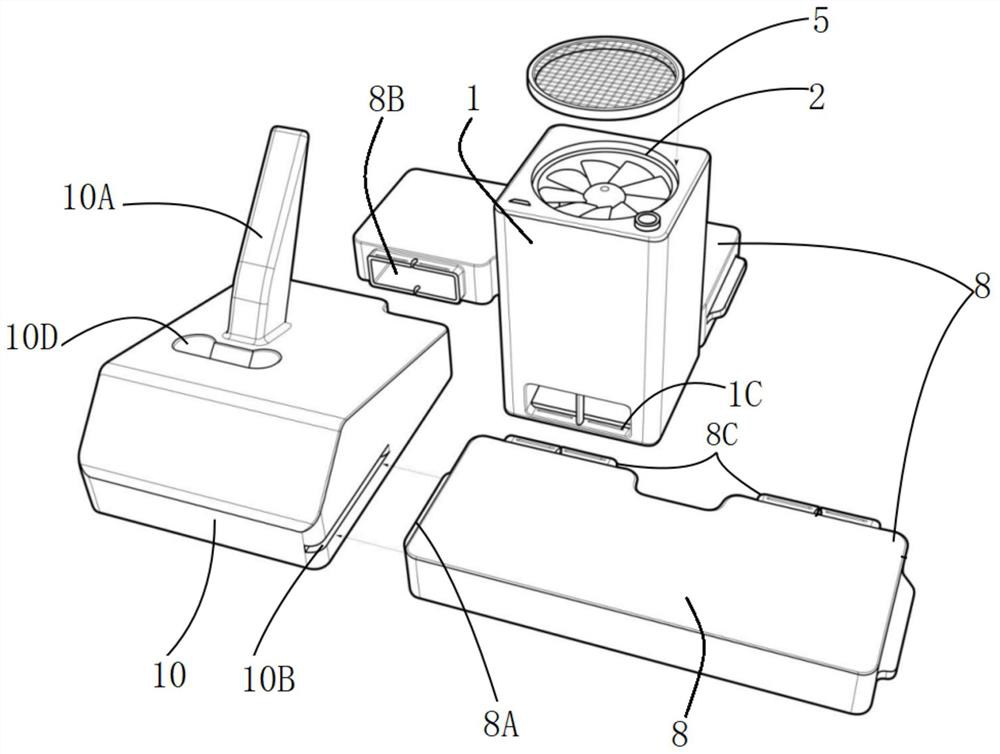

[0030] To simplify the expression, figure 2 Only a guide box 8, a base 10 and a shoe rack are schematically drawn. image 3 Only one base 10 is shown. Figure 7 Only schematically draw the air flow direction of the air pump box 1 connected with a group of guide box 8, base 10 and shoe drying rack.

[0031] The air pump box 1 includes an air pump box body, a fan 2 arranged in the air pump box body, a protective grid 5 installed outside the fan, an air pump box air supply port 1C provided on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com