Kitchen waste treatment device

The technology of kitchen waste and treatment device is applied in the field of kitchen waste treatment device, which can solve the problems of complex structure and complicated operation, and achieve the effects of good compression effect, convenient operation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following is further described in detail through specific implementation methods:

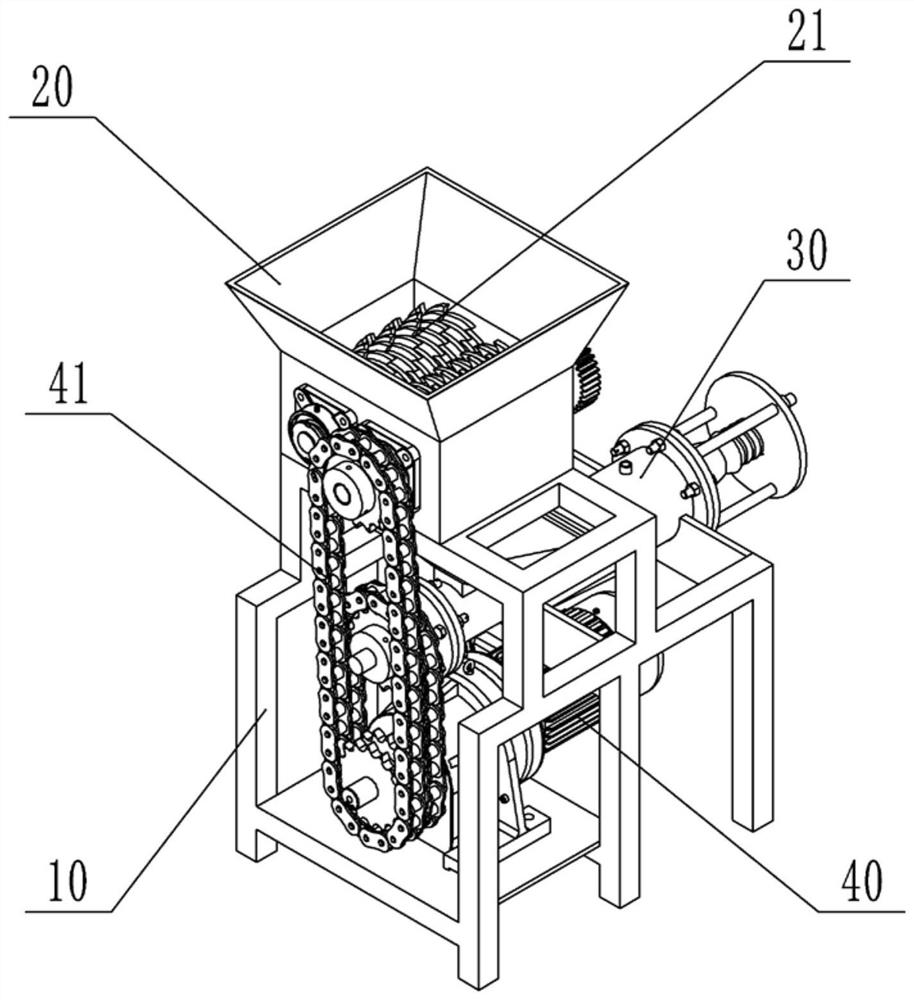

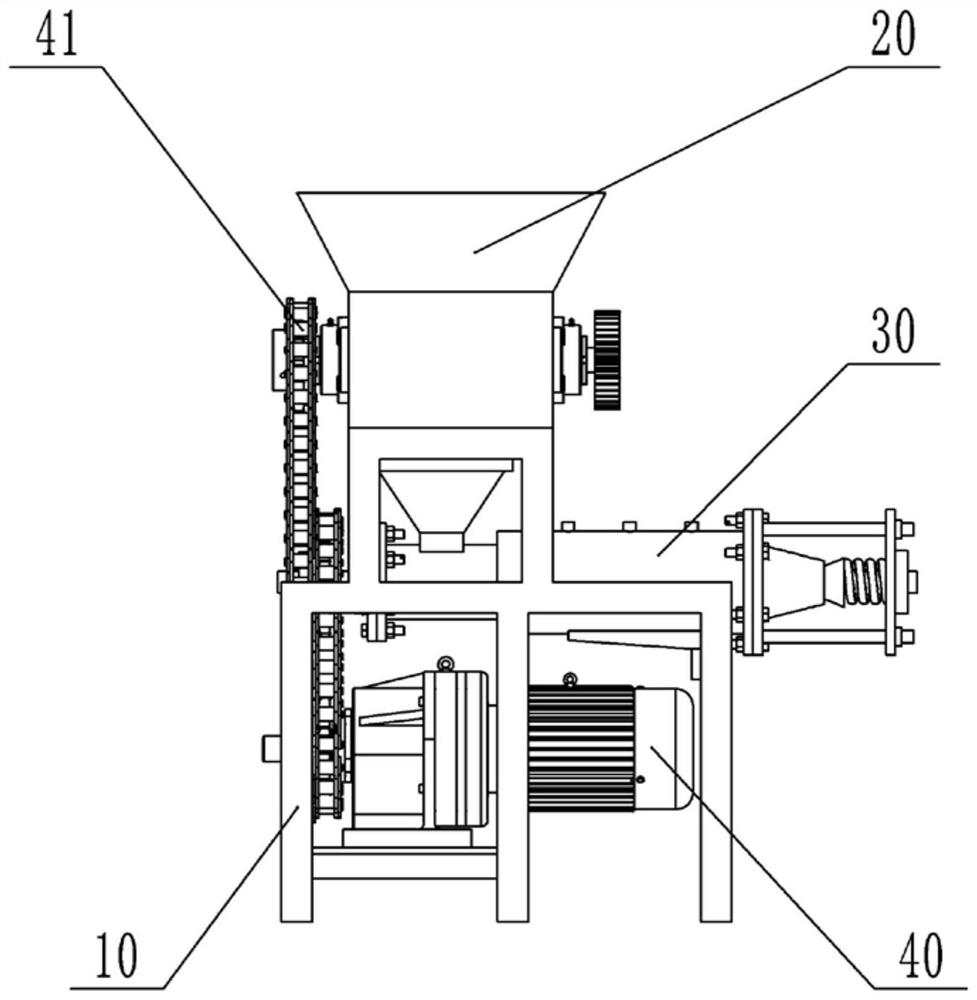

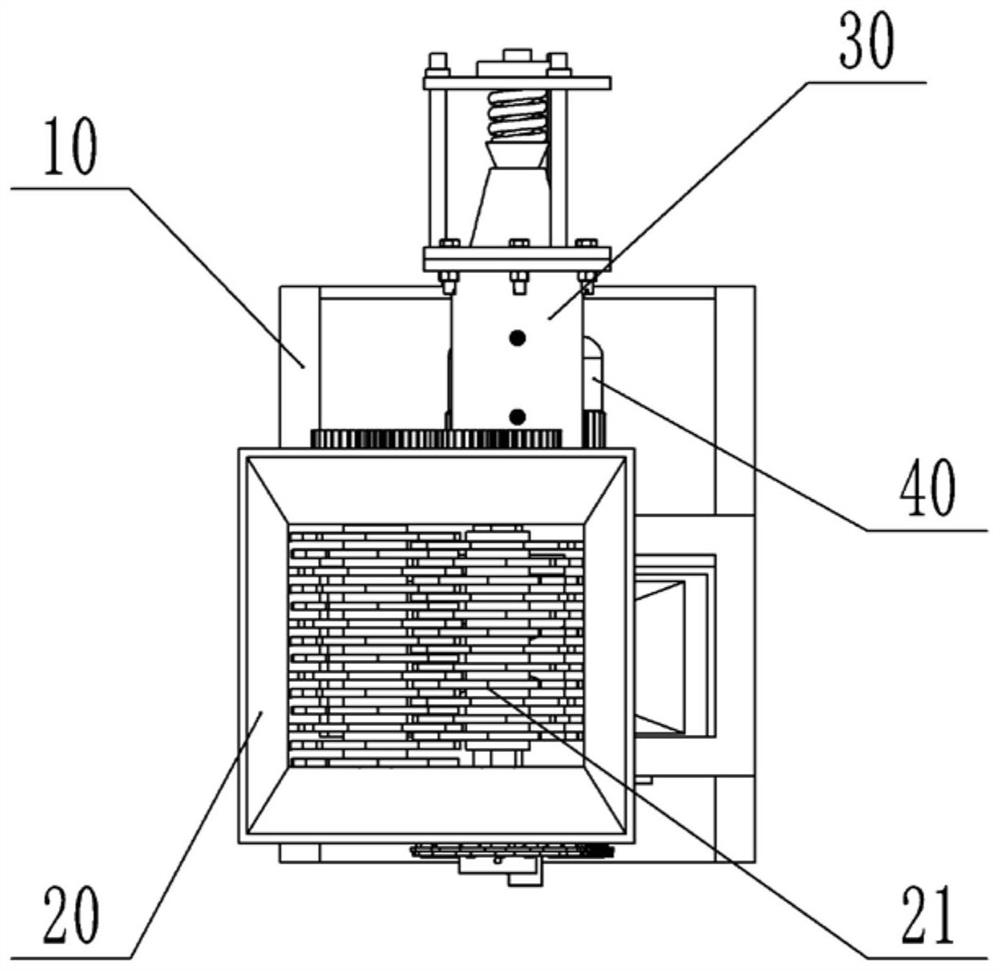

[0027] The reference signs in the accompanying drawings of the description include: frame 10, crushing device 20, crushing knife 21, dry-wet separation device 30, dry-wet separation shell 301, first screw 3021, second screw 3022, third screw 3023, bacteria outlet 3024, stirring rod 3025, sprocket 303, support plate 304, solid outlet 305, block 306, elastic member 307, feed inlet 308, liquid outlet 309, spray outlet 310, filter Net 311, motor 40, transmission chain 41.

[0028] This embodiment provides a kind of food waste pretreatment equipment, such as figure 1 , figure 2 As shown, the whole equipment mainly includes three parts, from bottom to bottom are the pulverizing device 20 , the dry-wet separating device 30 and the motor 40 , and the three devices are installed on the frame 10 .

[0029] Such as figure 1 , figure 2 and image 3 As shown, the crushing device 20 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com