Scrap collecting device for machining and using method thereof

A collection device and machining technology, applied in the direction of metal processing equipment, metal processing machine parts, manufacturing tools, etc., can solve the problems of inconvenient handling and reprocessing, different sizes, and uneven shapes of iron scraps, to ensure The layout is reasonable, the compression effect is good, and the layout is compact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

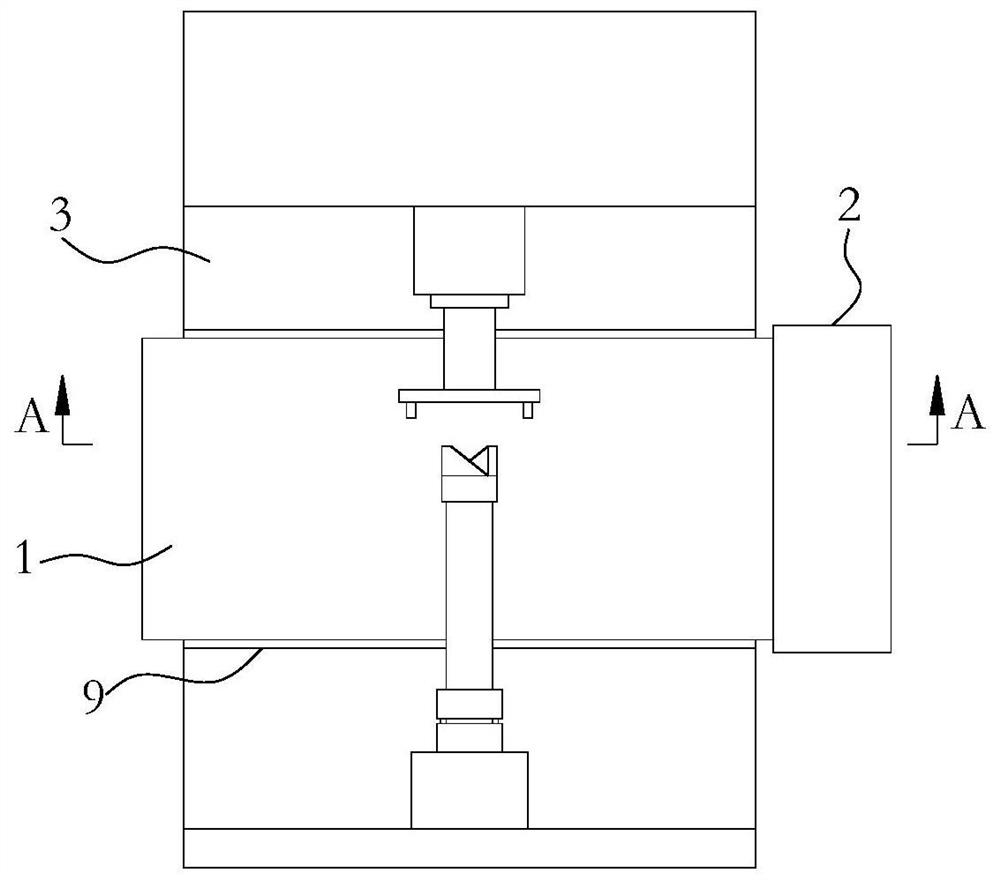

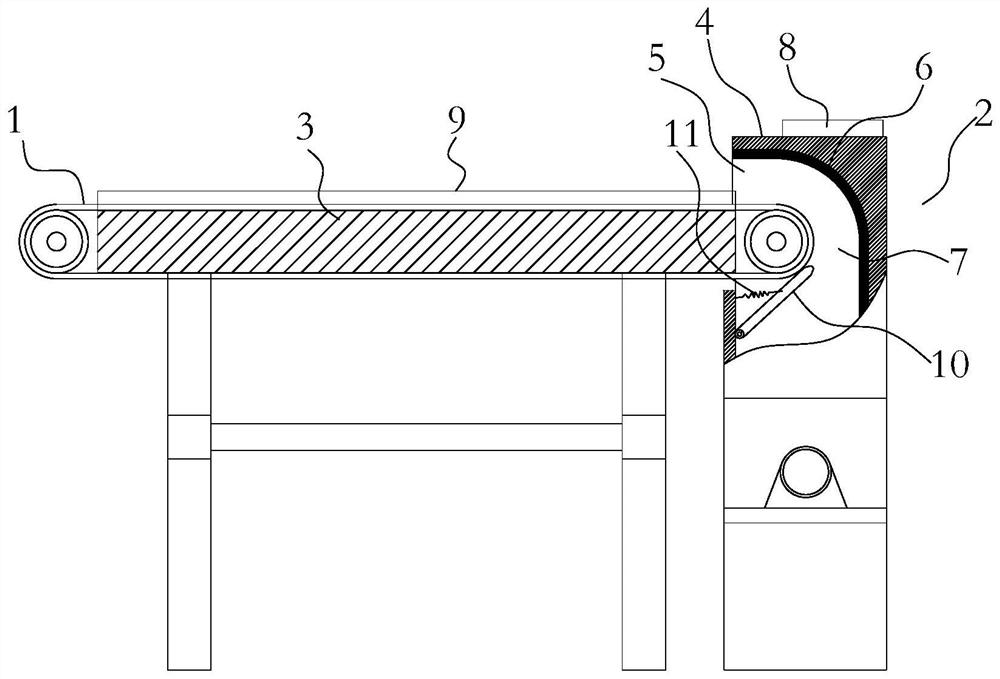

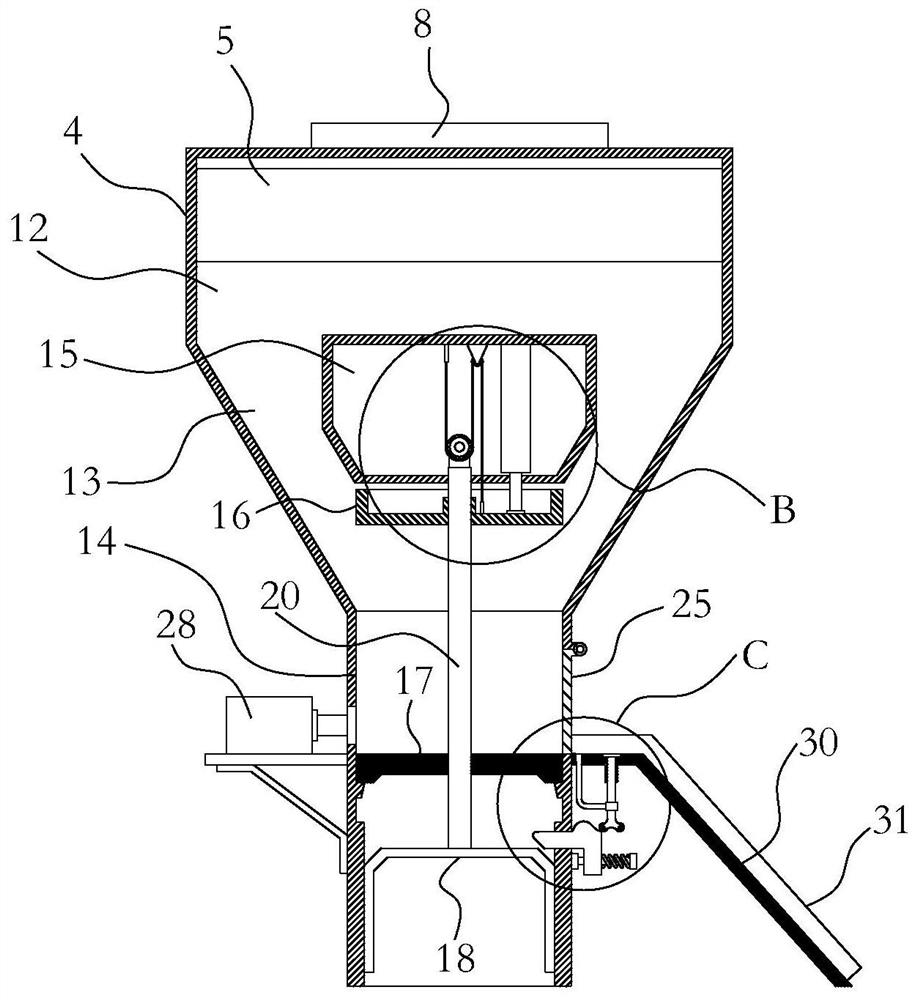

[0035] Such as Figure 1-9 As shown, a chip collection device for machining is installed on the machine tool for collecting and compressing iron filings and iron powder generated by machining. It mainly includes two major components, one part is The conveyor belt 1 for conveying the waste, and the other part is the collection compression box 2 for collecting and compressing the waste. The two cooperate to realize the functions of transportation, collection and compression.

[0036] From the perspective of realizing the transportation and collection of iron filings, such as figure 1 As shown in , the conveyor belt 1 is set at the processing station of the machine tool 3 workbench, for example: as figure 1 As shown in , the machine tool is provided with a fixture and a rotary tool, the workpiece is installed on the fixture, and the rotary tool is used to process the workpiece, and the conveyor belt 1 is located at the station near the fixture and the rotary tool. For ease of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com