Auxiliary equipment for railway open car unloading

A kind of auxiliary equipment, railway technology, applied in the direction of loading/unloading, conveyor objects, transportation and packaging, etc., can solve the problem that the goods cannot be effectively transported out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

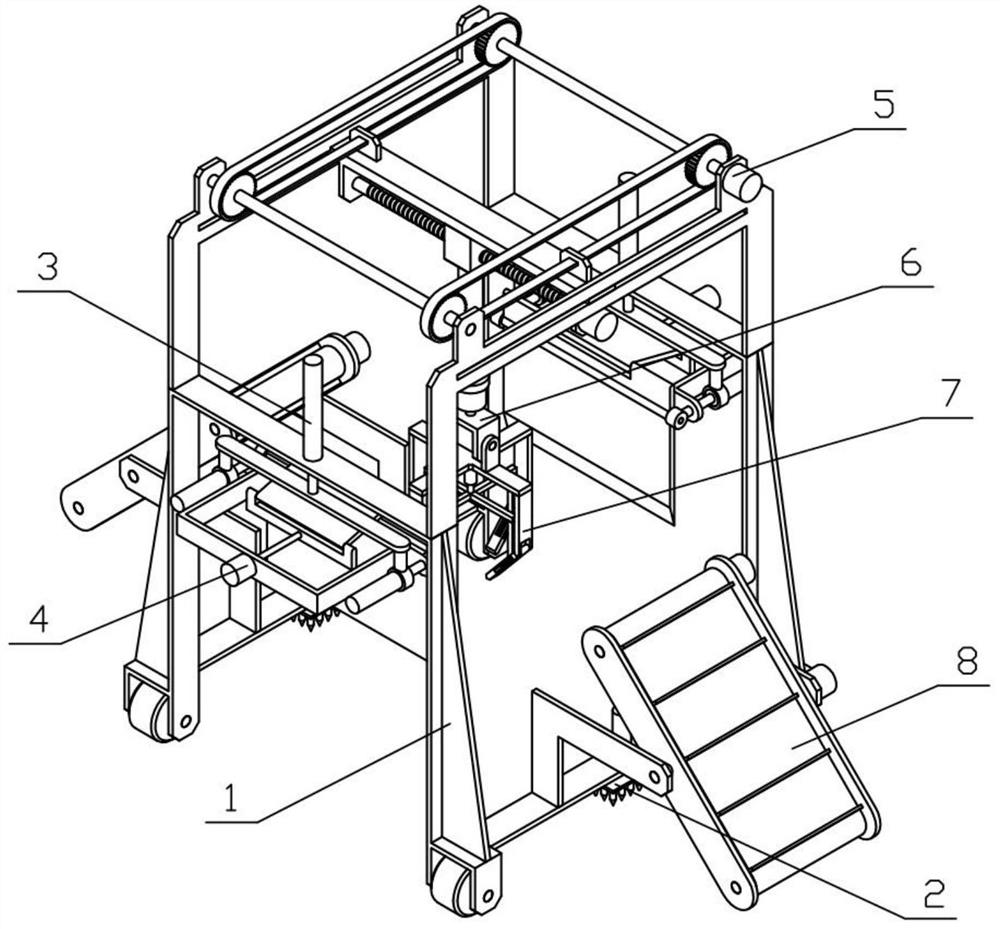

[0033] Combine below Figure 1-10 Description of this embodiment, the auxiliary equipment for unloading a railway gondola car includes a device bracket 1, a positioning mechanism 2, an insertion mechanism 3, a pushing mechanism 4, a moving mechanism 5, a clamping arm 6, a gripping hand 7 and a transport mechanism 8. The device bracket 1 The left and right sides of the lower end are fixedly connected with a positioning mechanism 2, the front and rear sides of the middle part of the device bracket 1 are fixedly connected with an insertion mechanism 3, and the two insertion mechanisms 3 are connected with a pushing mechanism 4, and the upper end of the device bracket 1 is connected with a mobile Mechanism 5, the lower end of the moving mechanism 5 is connected with the clamping arm 6, the lower end of the clamping arm 6 is fixedly connected with the gripping hand 7, two transport mechanisms 8 are provided, and the two transport mechanisms 8 are respectively fixedly connected to th...

specific Embodiment approach 2

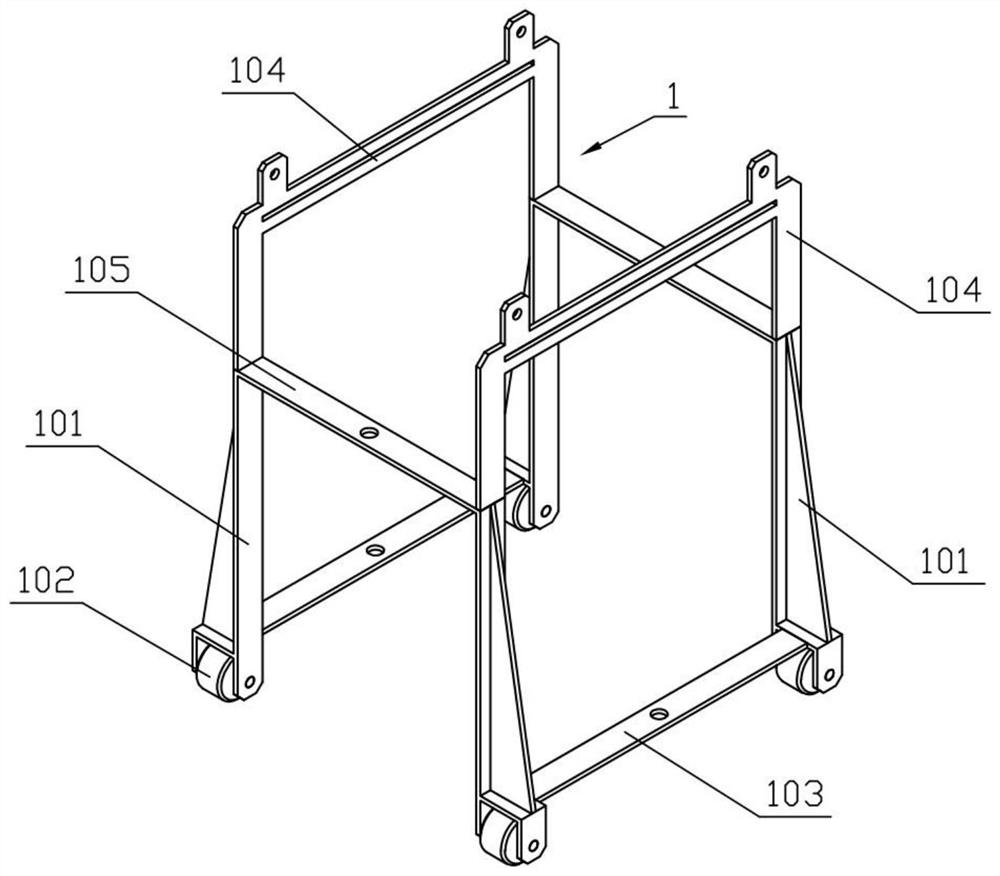

[0035] Combine below Figure 1-10 Describe this embodiment, this embodiment will further explain the first embodiment, the device bracket 1 includes a support frame I101, a moving wheel 102, a connecting bottom plate 103, a sliding bracket 104 and a connecting plate 105, and the support frame I101 is provided with two, two The lower ends of the two support frames I101 are rotatably connected with the movement wheels 102, the lower ends of the two support frames I101 are fixedly connected with the connecting bottom plate 103, and the upper ends of the two support frames I101 are fixedly connected with a connecting plate 105, and the two support frames I101 The upper ends of each are fixedly connected with sliding brackets 104.

specific Embodiment approach 3

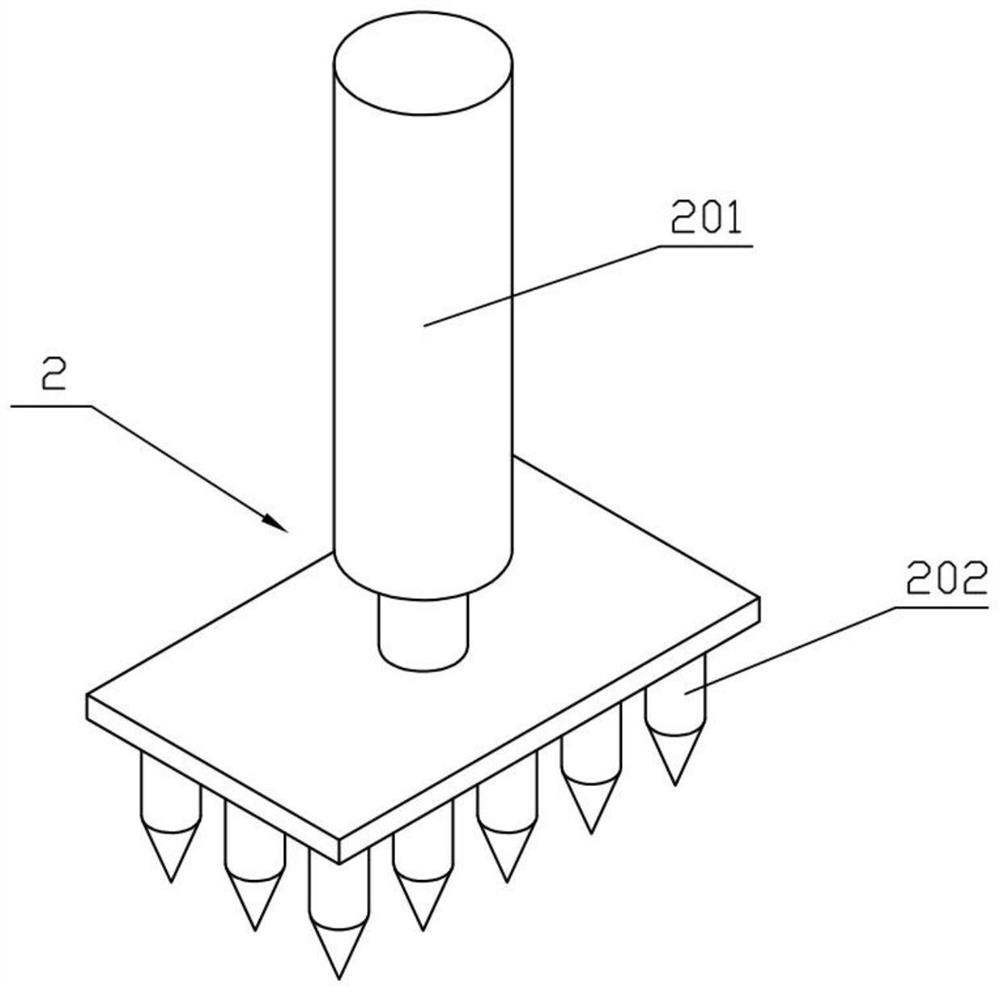

[0037] Combine below Figure 1-10 Describe this embodiment, and this embodiment will further explain the second embodiment. The positioning mechanism 2 includes a telescopic mechanism I201 and a positioning nail 202. Both are fixedly connected with telescoping mechanism I201.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com