Contact chip regenerating device and contact chip regenerating method

A technology of regeneration device and contact tip, applied in electrode accessories, other household appliances, hollow objects, etc., can solve the problems of unstable contact state, unstable welding current, and reduced welding quality, and achieve stable welding quality and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

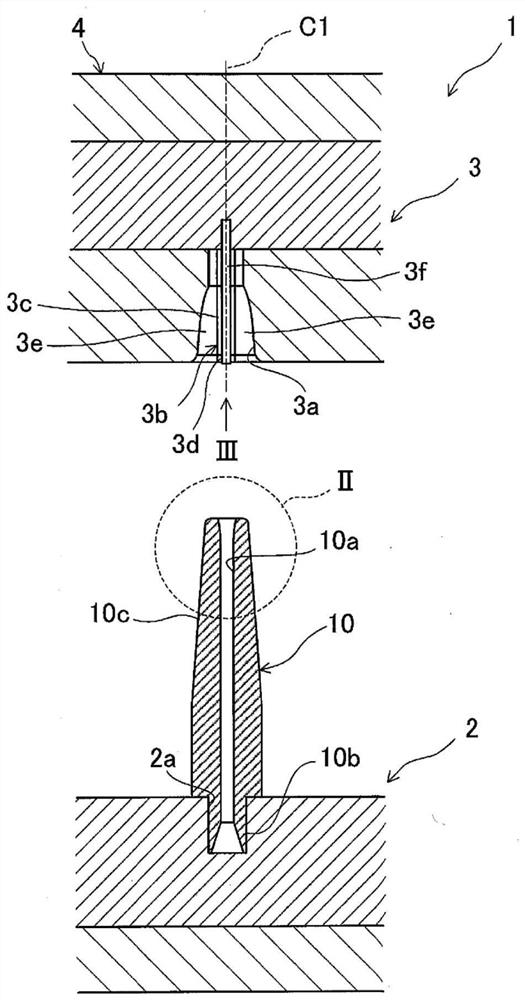

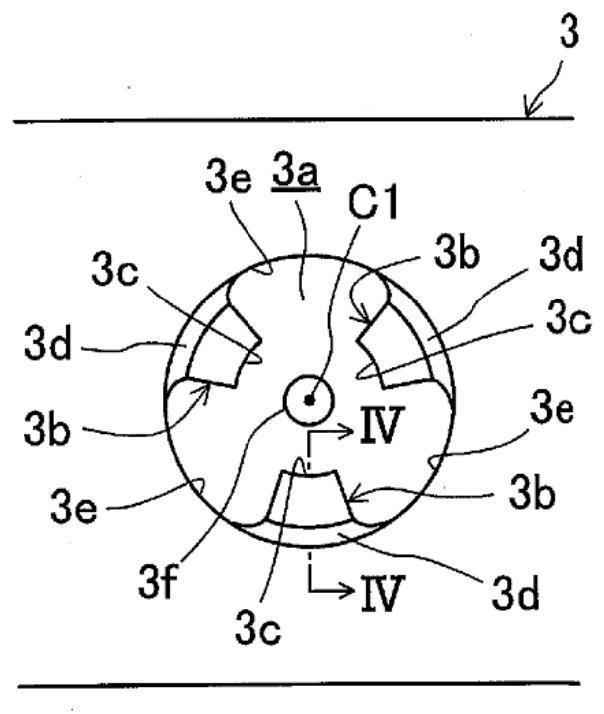

[0083] figure 1 It is a schematic cross-sectional view of the contact tip regeneration device 1 according to Embodiment 1 of the present invention. The contact tip regenerating device 1 is a device for regenerating a copper contact tip 10 mounted on an arc welding torch (not shown) after use, and includes: a first mold 2 capable of fixing the contact tip 10; The first mold 3 is placed opposite to the second mold 3 above it, and the press 4 is used to move the first mold 2 and the second mold 3 closer to or farther away from each other by raising and lowering the second mold 3 relative to the first mold 2 . .

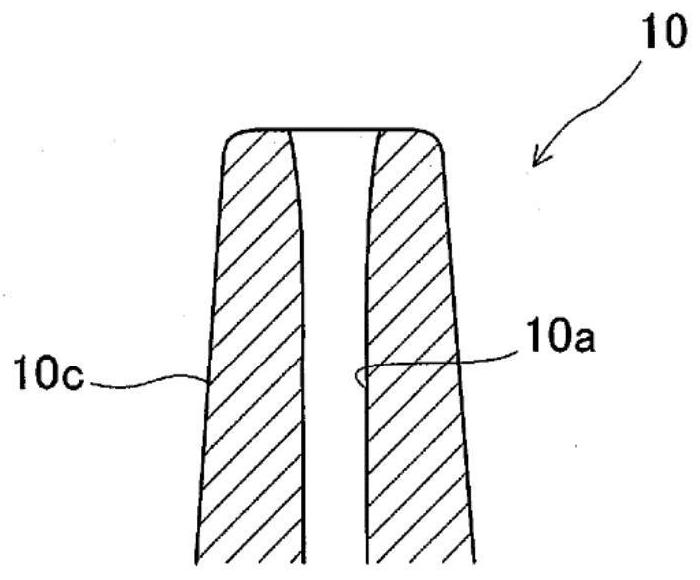

[0084] The contact tip 10 is in the shape of an elongated rod. The outer peripheral surface of the contact tip 10 has a main body portion 10c whose diameter gradually decreases linearly from the middle portion to the tip.

[0085] On the base end side of the contact tip 10, an approximately cylindrical external thread portion 10b protrudes, and a guide hole 10a with a ...

Embodiment approach 2

[0113] Figure 11 A contact tip regeneration device 1 according to Embodiment 2 of the present invention is shown. In this Embodiment 2, the details of devices other than the first mold 2 and the second mold 3 are disclosed. The first mold 2 and the second mold 3 are the same as Embodiment 1, so only the differences from Embodiment 1 are discussed below. to explain.

[0114] Such as Figure 11 and Figure 12 As shown, the contact tip regeneration device 1 according to Embodiment 2 includes a main body frame 5 serving as the skeleton of the contact tip regeneration device 1 , and a protective cover 1 a covering the entire main body frame 5 .

[0115] The protection cover 1a has an approximately semicircular cross-section on the front side of the device, and the protection cover 1a is in the shape of a box extending up and down, and an operation panel 1b for operating the contact tip regeneration device 1 is provided on the upper part.

[0116] The main body frame 5 has an u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com