Tool for machining a workpiece, and machine tool

A technology of cutting processing and machine tools, which is applied in the direction of manufacturing tools, metal processing equipment, sawing machine tools, etc., can solve the problems of chip leakage, insufficient chip removal, and influence of processing time, so as to achieve less heat generation and improve service life , the effect of increasing the effective area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

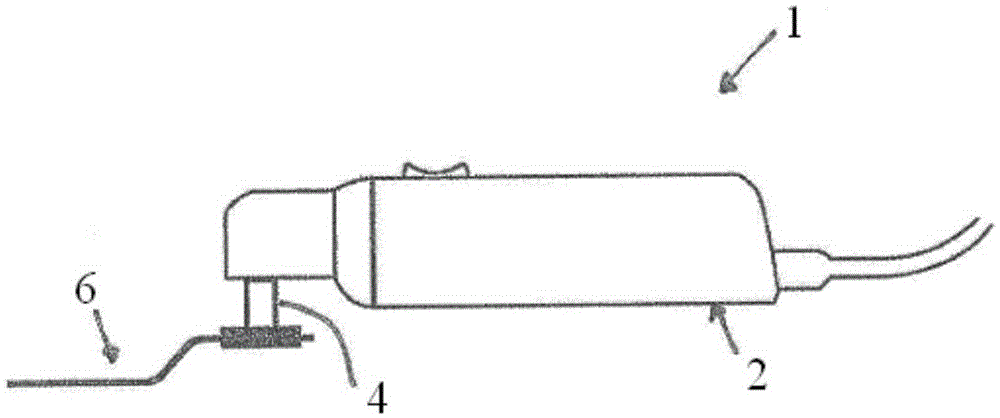

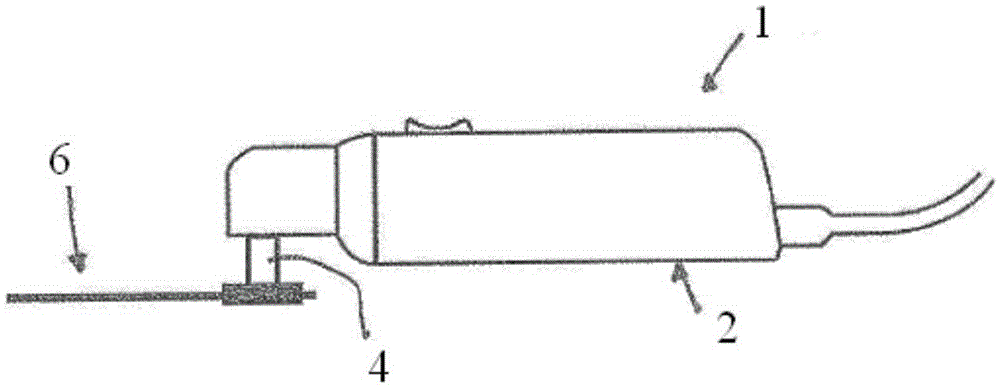

[0046] exist figure 1 and figure 2 The manually guided power tool 1 shown in has in the usual manner a housing 2, an electric drive motor, an electric control device, operating elements such as switches and the like, a transmission and a tool spindle drivable by means of the drive motor 4. The most varied tools 6 for cutting workpieces 6 can be fastened on the tool spindle, so that the tools 6 fastened on the tool spindle 4 can be driven in particular vibratingly for machining the workpieces.

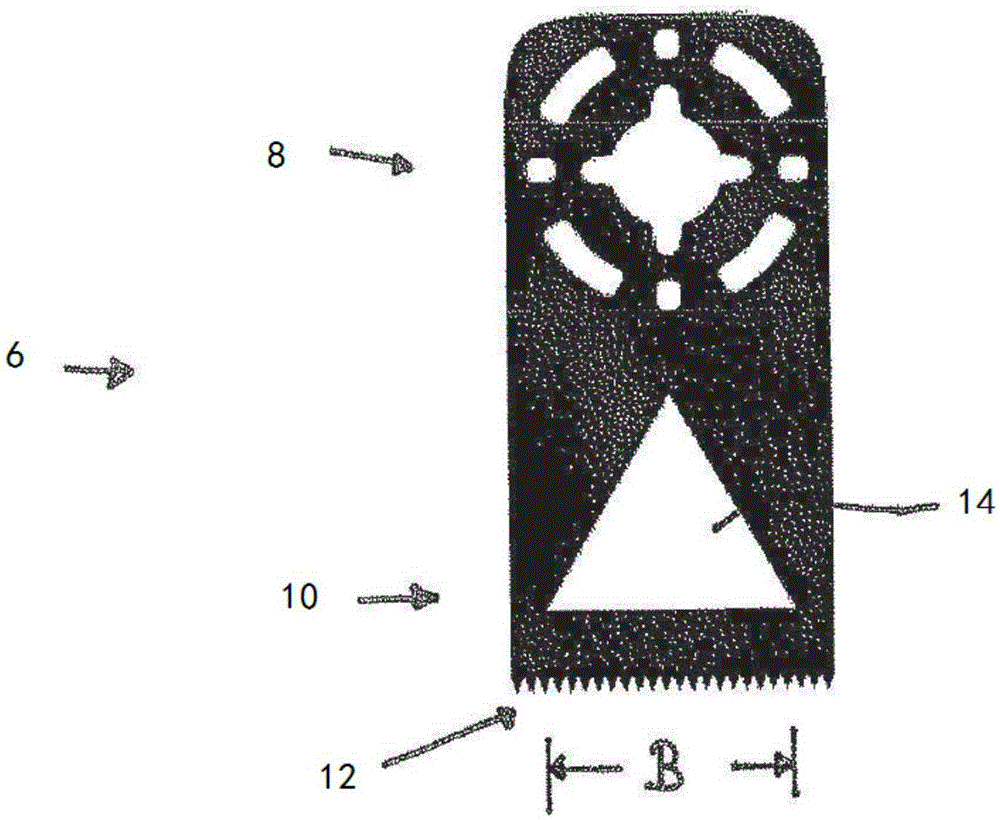

[0047] as in particular Figure 3a to Figure 9b As stated, the tool 6 has a tool body made of steel. The tool 6 is fastened to the tool spindle 4 of the power tool 1 by means of a fastening section 8 having a plurality of through holes in a known manner. The processing section 10 is associated with a toothing 12 which consists of hardened steel. The machining section 10 and / or in particular the toothing 12 can be diamond-coated and / or covered with cemented carbide.

[0048] The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com