Sectional material cuboid structure and modular exhibition sectional material building system

A cuboid structure and profile technology, applied in the field of exhibition stands, can solve the problems of long assembly cycle and cumbersome assembly process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

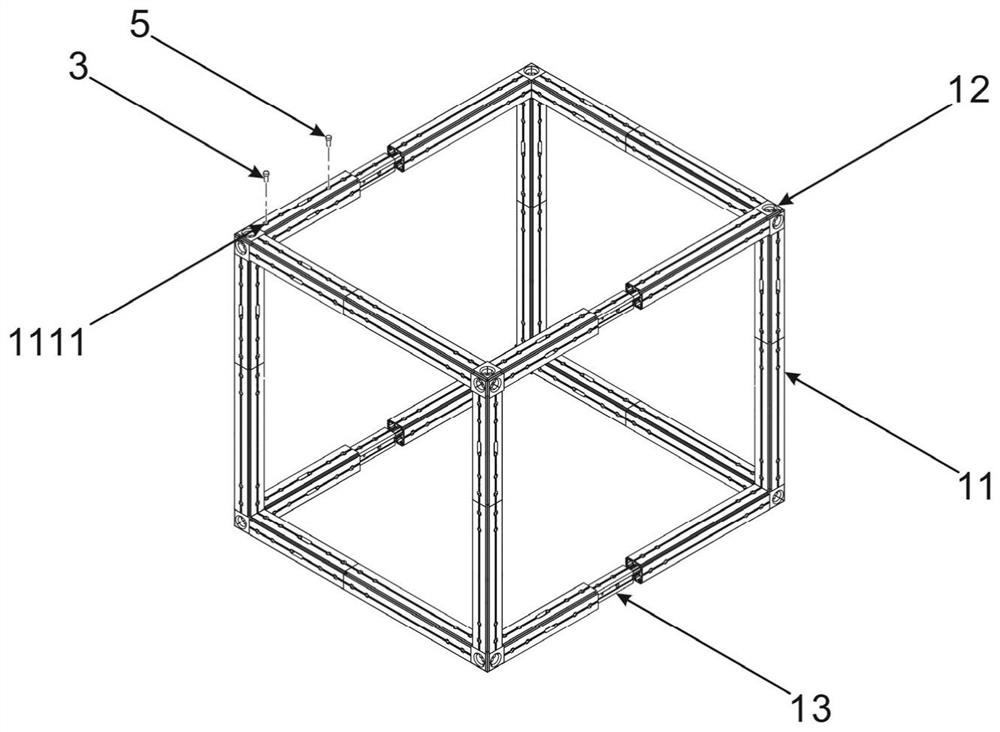

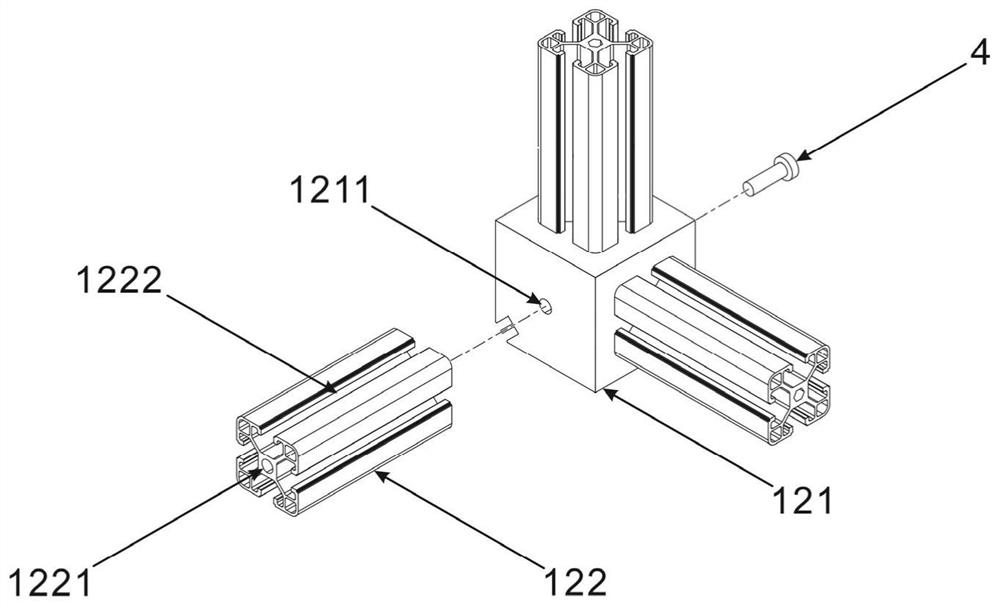

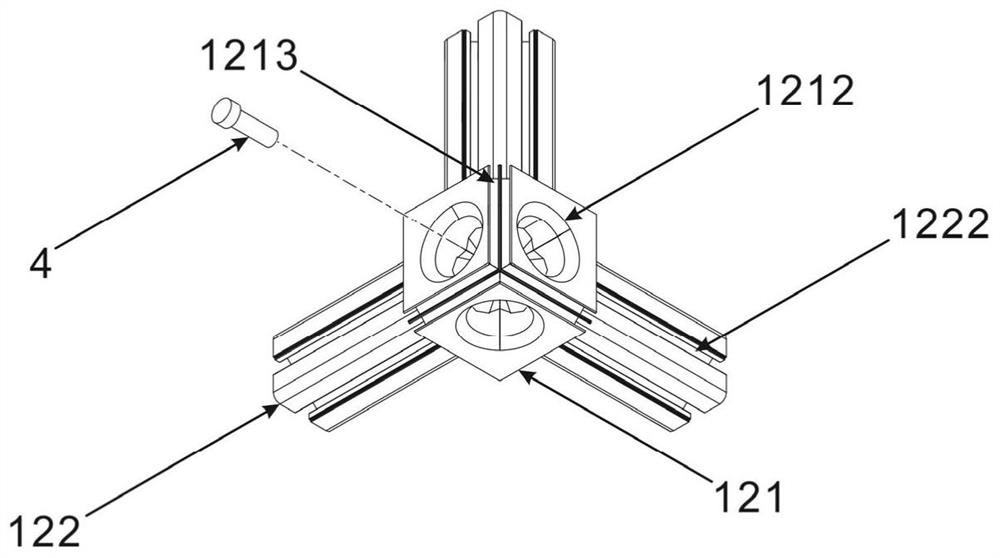

[0044] The invention provides a profile cuboid structure, such as Figure 1-Figure 4 As shown, the profile cuboid structure 1 includes a three-dimensional profile 11 and a tee connector 12, wherein: the tee connector 12 includes a connector body 121 and a plug-in inner core 122, and the connector body 121 is provided with three two-by-two vertically connected negative surfaces. , each of the negative faces is provided with a plug-in inner core 122; the cross-sectional shape of the three-dimensional profile 11 is set as a hollow square, and the plug-in inner core 122 is inserted in the three-dimensional profile 11 along the end surface of the three-dimensional profile 11, and the three-dimensional profile 11 A first fixing hole 1111 is provided on the side, and the end of the first fastener 3 passes through the first fixing hole 1111 to connect with the plug-in inner core 122; at least one side of the three-dimensional profile 11 is provided with a first installation hole 1112 ...

Embodiment 2

[0065] Embodiment 2 is based on Embodiment 1: the present invention provides a modular exhibition profile building system, such as Figure 10-Figure 16 As shown, the modularized exhibition profile building system includes a profile rectangular plane structure 2 and a profile rectangular parallelepiped structure 1, wherein: the profile rectangular parallelepiped structure 1 is set as a rectangular parallelepiped frame structure; the profile rectangular plane structure 2 includes a two-dimensional profile 21 and a rectangular connector 22 , the cross-sectional shape of the two-dimensional profile 21 is set as a hollow square, and the right-angle connector 22 is provided with two insertion parts 222 perpendicular to each other. The three-dimensional profile 21 and the right-angle connector 22 surround a rectangular frame structure; the side of the two-dimensional profile 21 is provided with a second installation hole 2111, and the three-dimensional profile 11 on one side of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com