A Thermal Lodging Type Low Aging Speed Cable

An aging speed, thermal lodging technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of reduced service life, hidden dangers, accelerated aging speed, etc., to improve heat dissipation, prolong service life, and reduce aging speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

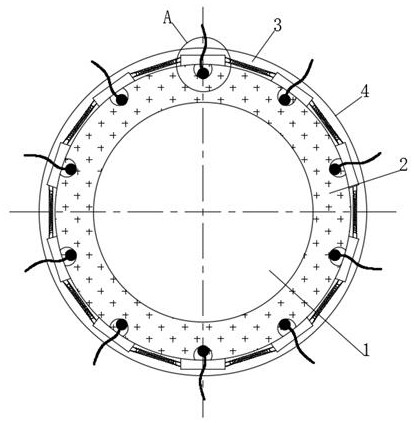

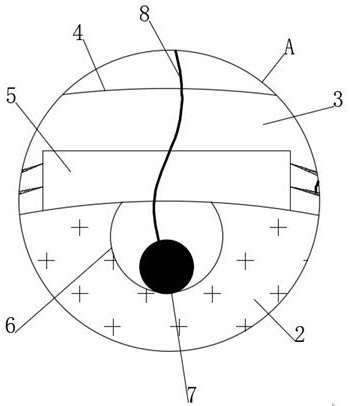

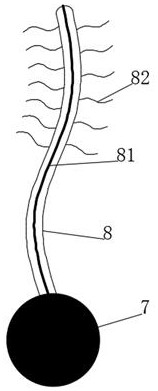

[0039] see Figure 1-2 , a thermal lodging type cable with low aging speed, comprising a core layer 1, the outer end of the core layer 1 is wrapped with a sheath layer 2, the outer end of the sheath layer 2 is wrapped with an outer protective layer 3, and the outer surface of the outer protective layer 3 is Wrapped with a wall-attached heat insulation layer 4, the outer protective layer 3 is inlaid with a plurality of evenly distributed outer connection blocks 5, one end of the outer connection block 5 is fixedly connected to the outer surface of the sheath layer 2, and the outer surface of the sheath layer 2 is dug with A plurality of ball grooves 6 corresponding to the outer connection block 5, heat conduction balls 7 are placed inside the ball grooves 6, the outer ends of the heat conduction balls 7 are fixedly connected with self-lodging rods 8, and the self-lodging rods 8 sequentially penetrate the outer connection block 5, the outer protection Layer 3 and the wall-adheri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com