Quick-freezing technology of fresh broad beans

A broad bean, fresh technology, applied in the direction of preservation of fruits and vegetables, preservation of fruits/vegetables by freezing/refrigeration, food preservation, etc., to achieve the effects of maintaining freshness, preventing deformation, and enhancing cohesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

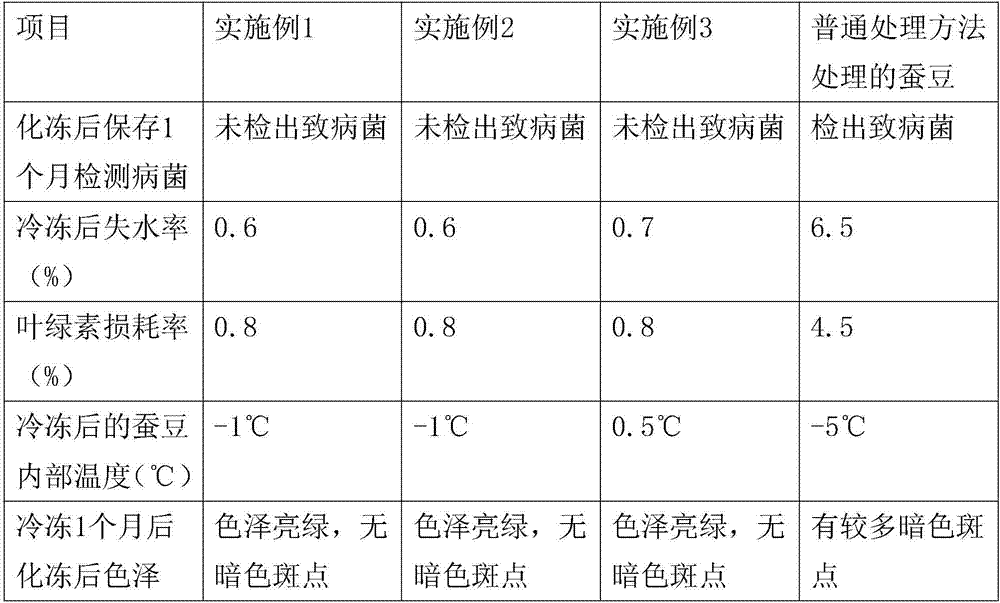

Examples

Embodiment 1

[0022] A quick freezing process for fresh broad beans includes the following steps:

[0023] (1) Remove 3% of the water from the fresh broad beans, then spray with hot white vinegar solution, then let the broad beans stand for 1 hour, and then put the broad beans in an environment of 10-15°C for 2 hours;

[0024] (2) Take out the broad beans and rinse them with water, dry them naturally, and then store the broad beans in an environment with a temperature of 25-30°C and a relative humidity of 50-60% for 2-4 hours;

[0025] (3) Take out the broad beans and soak them with soaking liquid;

[0026] The soaking liquid includes the following parts by weight: 8 parts of Pueraria lobata root powder, 5 parts of mint leaf extract, 1.5 parts of chitosan ester, 2.5 parts of saffron pollen, 0.8 parts of 4-terpineol, 3 parts of natural lotus seed extract , 2.5 parts of sunflower oil, 0.4 parts of α-terpineol, and 180 parts of ethanol; the preparation method is as follows: the raw materials are mixed...

Embodiment 2

[0034] A quick freezing process for fresh broad beans includes the following steps:

[0035] (1) Remove 3% of the water from the fresh broad beans, then spray with hot white vinegar solution, then let the broad beans stand for 1 hour, and then put the broad beans in an environment of 10-15°C for 2 hours;

[0036] (2) Take out the broad beans and rinse them with water, dry them naturally, and then store the broad beans in an environment with a temperature of 25-30°C and a relative humidity of 50-60% for 2-4 hours;

[0037] (3) Take out the broad beans and soak them with soaking liquid;

[0038] The soaking liquid includes the following parts by weight: 5 parts of Pueraria lobata root powder, 4 parts of mint leaf extract, 1 part of chitosan ester, 2 parts of saffron pollen, 0.5 part of 4-terpineol, 2 parts of natural lotus seed extract , 2 parts of sunflower oil, 0.2 parts of α-terpineol, and 150 parts of ethanol; the preparation method is as follows: mix the raw materials uniformly.

[...

Embodiment 3

[0046] A quick freezing process for fresh broad beans includes the following steps:

[0047] (1) Remove 3% of the water from the fresh broad beans, then spray with hot white vinegar solution, then let the broad beans stand for 1 hour, and then put the broad beans in an environment of 10-15°C for 2 hours;

[0048] (2) Take out the broad beans and rinse them with water, dry them naturally, and then store the broad beans in an environment with a temperature of 25-30°C and a relative humidity of 50-60% for 2-4 hours;

[0049] (3) Take out the broad beans and soak them with soaking liquid;

[0050] The soaking liquid includes the following parts by weight: 10 parts of Pueraria lobata root powder, 6 parts of mint leaf extract, 2 parts of chitosan ester, 3 parts of saffron pollen, 1 part of 4-terpineol, 4 parts of lotus seed natural extract , 3 parts of sunflower oil, 0.6 parts of α-terpineol, and 200 parts of ethanol; the preparation method is as follows: mix the raw materials uniformly.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com