Clamp structure for cable end and auxiliary device with the clamp structure

A technology of cable ends and auxiliary devices, which is applied in the direction of circuits, electrical components, circuit/collector components, etc., can solve the problems of potential safety hazards, time-consuming and labor-intensive problems, improve efficiency, reduce labor, and facilitate cable work areas Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Such as Figure 1 to Figure 19 As shown, the cable end is equipped with a clamp structure, including an end clamp frame 1;

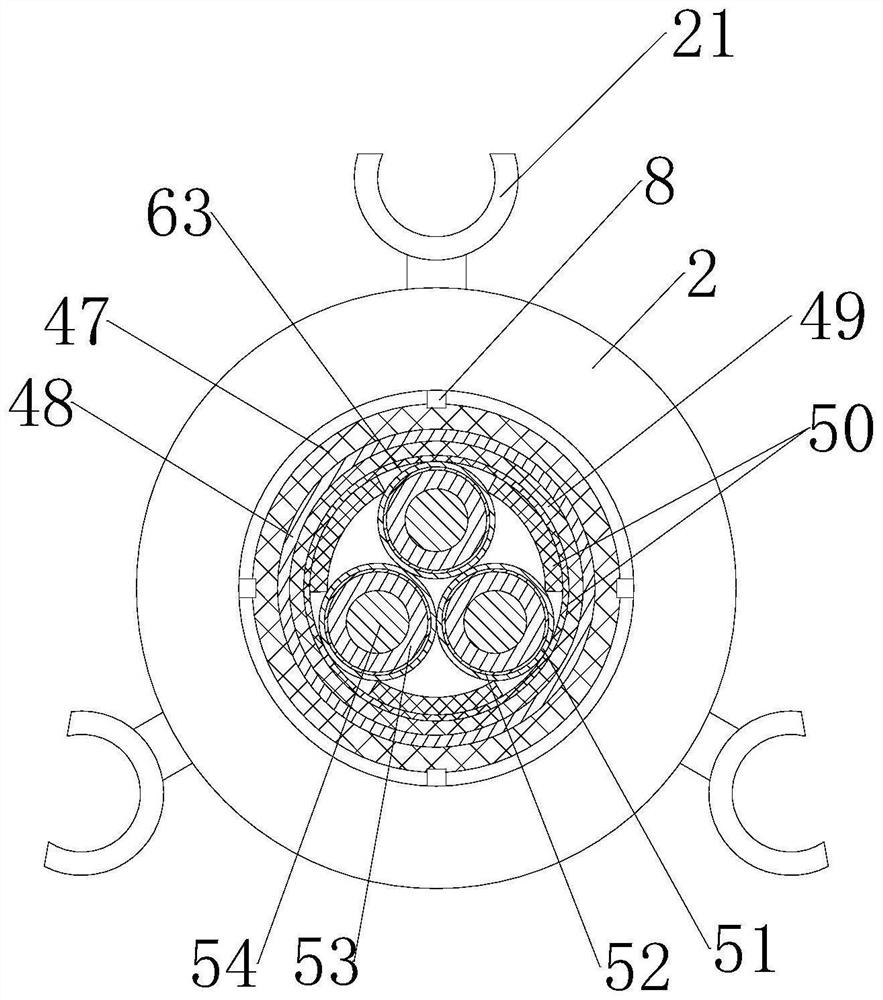

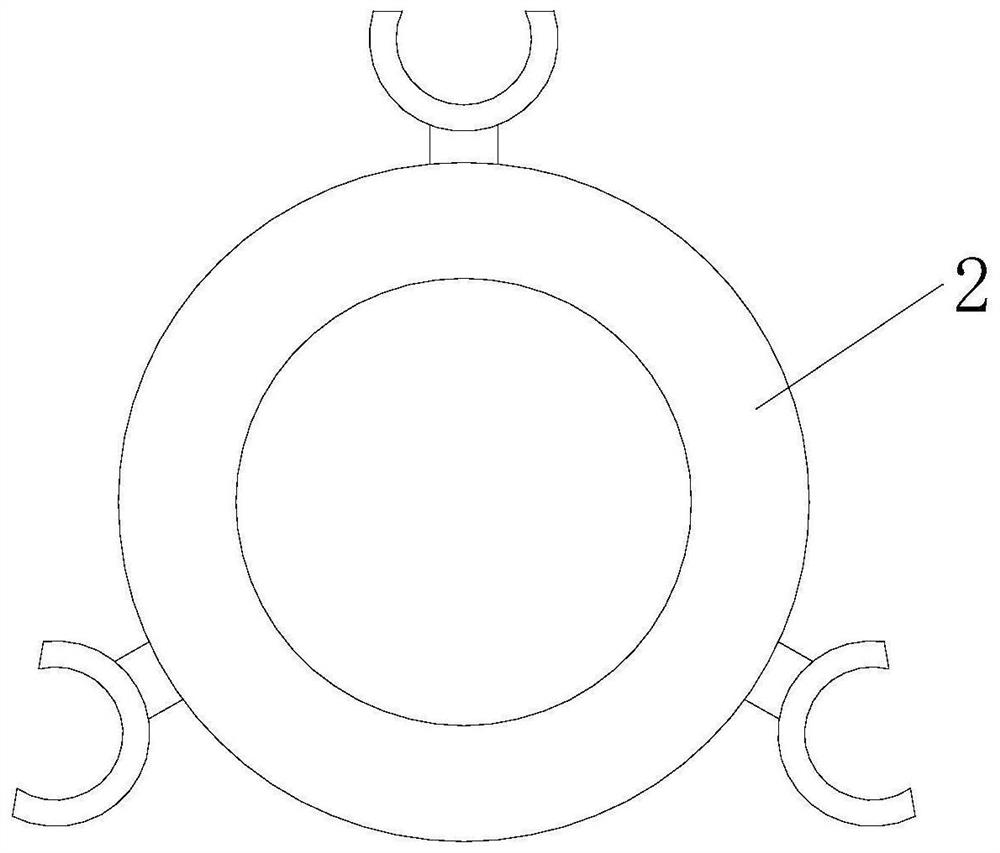

[0064] An end clamping tube 2 is installed on the end clamp frame 1, and the end clamping tube 2 has a hollow end clamping area 3 along its axial direction, and the end clamping area 3 runs through the inner end and the outer end of the end clamping tube 2. There is a hollow interlocking movable cavity 4 inside the tube wall of the holding tube 2, and the interlocking movable cavity 4 divides the tube wall of the terminal clamping tube 2 into the terminal inner tube section 5 and the terminal outer tube section 6;

[0065] There are several groups of interlocking port groups on the end inner pipe section 5, each group of interlocking port groups has at least two interlocking ports 7 communicating with the interlocking movable chamber 4, and the interlocking ports 7 are slidably provided with The interlocking slider 8, the middle part of the inter...

Embodiment 2

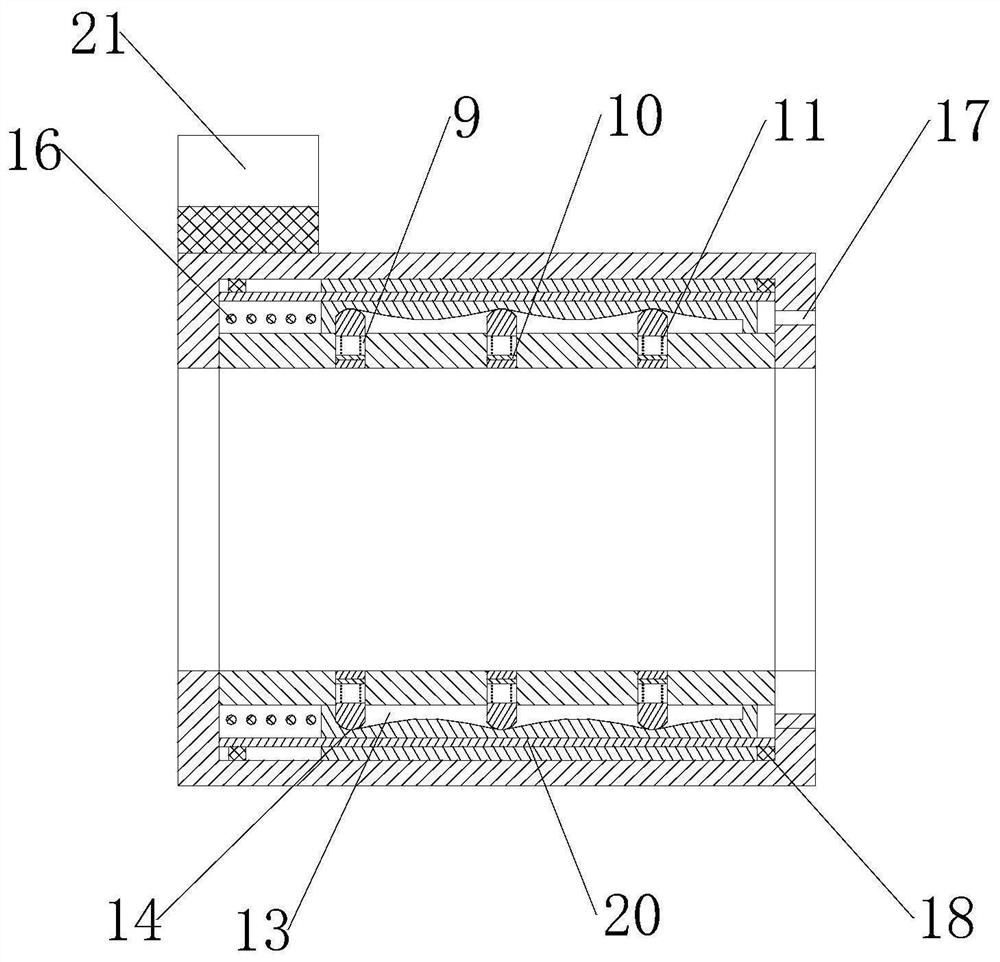

[0072] This embodiment makes the following further limitations on the basis of Embodiment 1: the end clamping tube 2 is provided with a lower clamping limit ring 18 and a high clamping limit ring 18 located in the interlocking movable chamber 4 . The positioning ring 19 , the lower clamping limiting ring 18 and the upper clamping limiting ring 19 are respectively located on both sides of the interlocking movable tube 12 .

[0073] In this embodiment, the terminal clamping vent hole 17 can be arranged in the area surrounded by the lower clamping limiting ring 18 .

Embodiment 3

[0075] This embodiment makes the following further limitations on the basis of Embodiment 1: the end clamping tube 2 is provided with an end clamping guide rod that is located in the interlocking activity chamber 4 and runs through both ends of the interlocking activity tube 12 20. The interlocking movable tube 12 can move axially relative to the clamping guide rod 20 at the end.

[0076] In this embodiment, there may be two terminal clamping guide rods 20 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com