Three-phase power supply multi-speed compressor and implementation control method

A three-phase power supply and control method technology, which is applied in the field of air-conditioning compressors, can solve the problems that fixed-speed compressors cannot be satisfied, cannot completely replace fixed-speed compressors, and cannot be reduced and adjusted for fixed-speed compressors, and achieves a reduction in technology and Cost input, effect of changing compressor speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

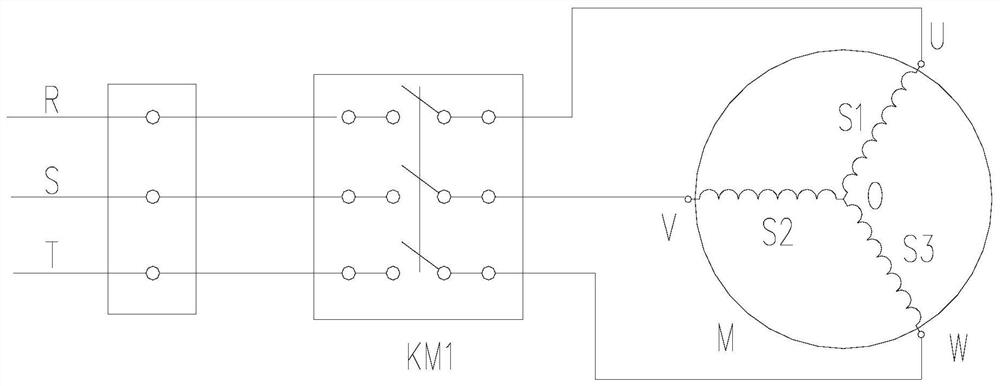

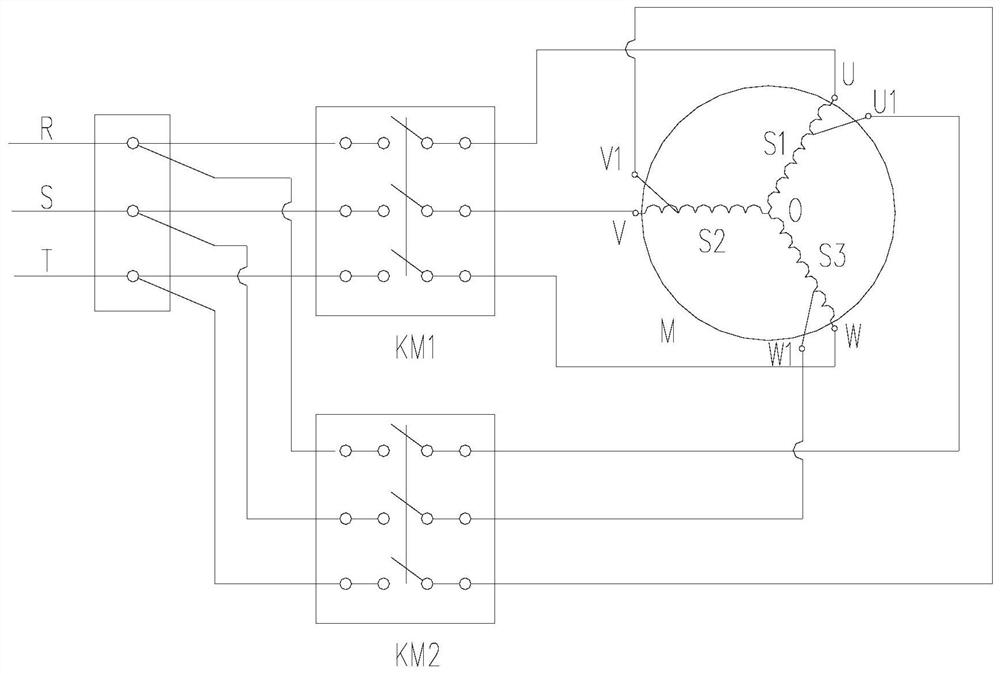

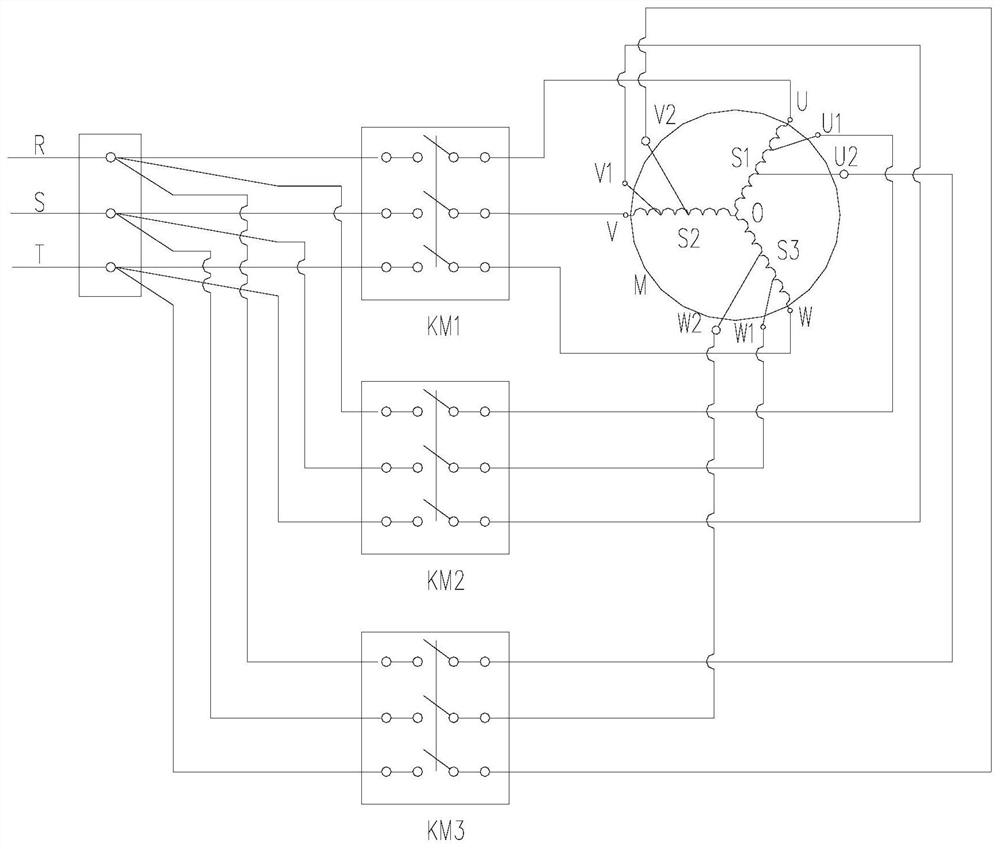

[0026] see figure 2 A kind of three-phase power multi-speed compressor, relates to compressor motor, described compressor motor comprises stator winding S1, stator winding S2, stator winding S3, and described stator winding S1, stator winding S2, stator winding S3 are respectively connected Connecting terminal U, connecting terminal V, connecting terminal W are connected to the connecting terminals of three-phase power supply R, three-phase power supply S, and three-phase power supply T through the first switch; also include connecting terminal U1, connecting terminal V1, connecting terminal W1 The middle sections of the stator winding S1, the stator winding S2, and the stator winding S3 are respectively connected to the terminal U1, the terminal V1, and the terminal W1, and are connected to the three-phase power supply R, the three-phase power supply S, and the three-phase power supply through the second switch. The terminal of the three-phase power supply T.

[0027] When ...

Embodiment 2

[0039] For this purpose, see figure 2 : This embodiment also provides a method for realizing the control of a three-phase power multi-speed compressor, which involves a compressor motor, and the compressor motor includes a stator winding S1, a stator winding S2, and a stator winding S3, and the stator winding S1 , stator winding S2, and stator winding S3 are respectively connected to terminal U, terminal V, and terminal W, and are connected to the terminals of three-phase power supply R, three-phase power supply S, and three-phase power supply T through the first switch; Stator windings S1, stator windings S2, and stator windings S3 of the electromechanical motor are connected to terminals U1 V1 W1 in the middle section to change the effective resistance of the stator windings, and are connected to the three-phase power supply R, The terminals of the three-phase power supply S and the three-phase power supply T; when the first switch is turned on, the second switch is turned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com