Brushless DC motor with mold cover for ground protection

A technology of brush DC motor and casting mold, which is applied in the field of motor with grounding structure, can solve the problems that the bearing cannot be effectively prevented from electrolytic corrosion, and the bearing is easily exposed to the outside, so as to achieve the effect of preventing electrolytic corrosion and preventing separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

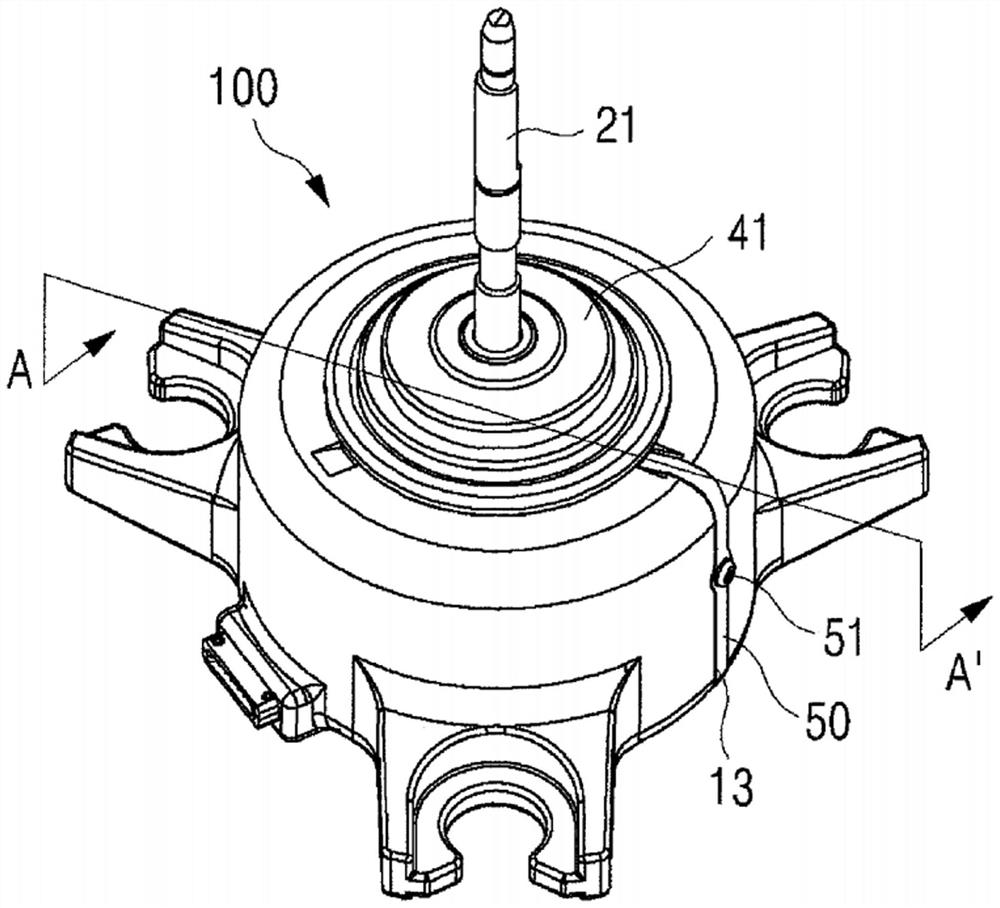

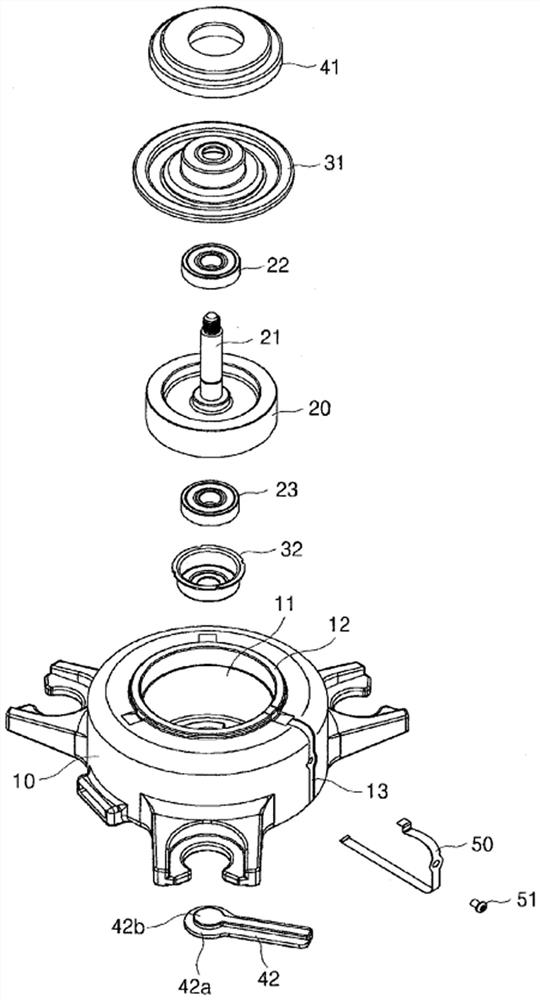

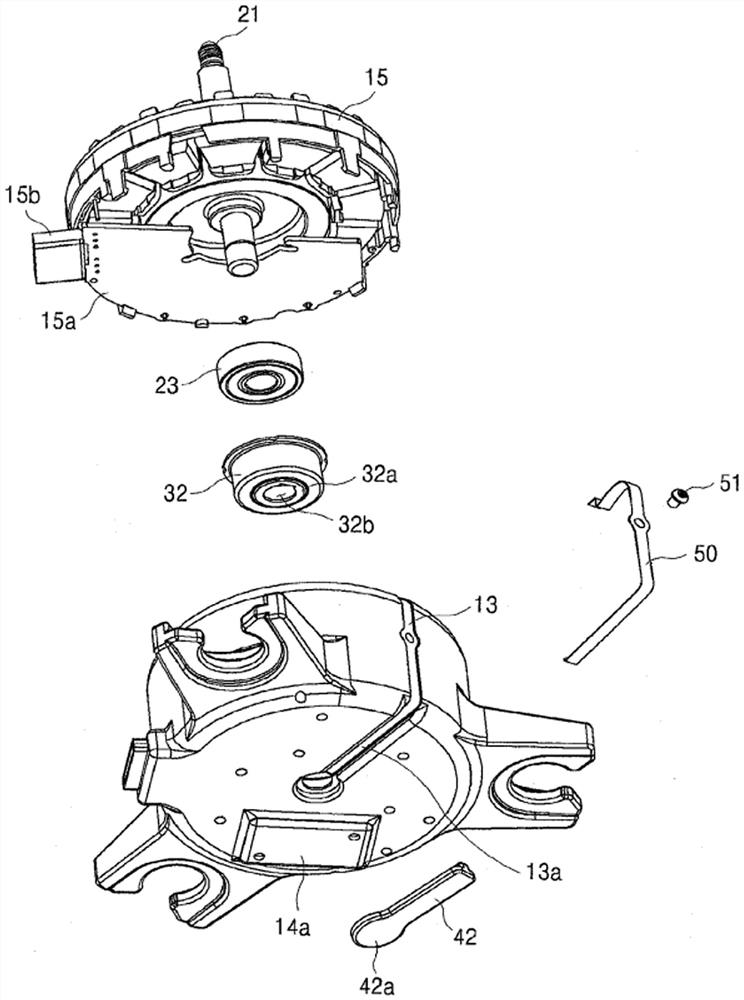

[0035] figure 1 It is an exploded view of the above motor 100 according to the present invention; figure 2 It is an exploded schematic diagram of the above motor 100 according to the present invention; image 3 It is an exploded schematic view of the bottom of the motor 100 according to the present invention.

[0036] from Figure 1 to Figure 3 As can be seen in the figure, the motor 100 according to the present invention may include a housing 10 , a rotor 20 , an upper bearing cover 31 , a lower bearing seat 32 , an upper protective member 41 and a molded end cover 42 .

[0037] The housing 10 has a hollow portion 11 in which a space in the middle is hollow, and an annular flange portion 12 protrudes upward along an upper portion of the hollow portion 11 . A rotor 20 coupled to and rotating with a shaft 21 is located within the hollow portion 11 . The first groove 13 is where the first ground member 50 is placed. The first groove 13 is formed by the flange portion 12 or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com