Walking-behind seeder

A planter and walk-behind technology, applied in the field of walk-behind seeders, can solve the problems of large volume, four corners, and difficult access to small arable land, and achieve the effect of reducing operation procedures and labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

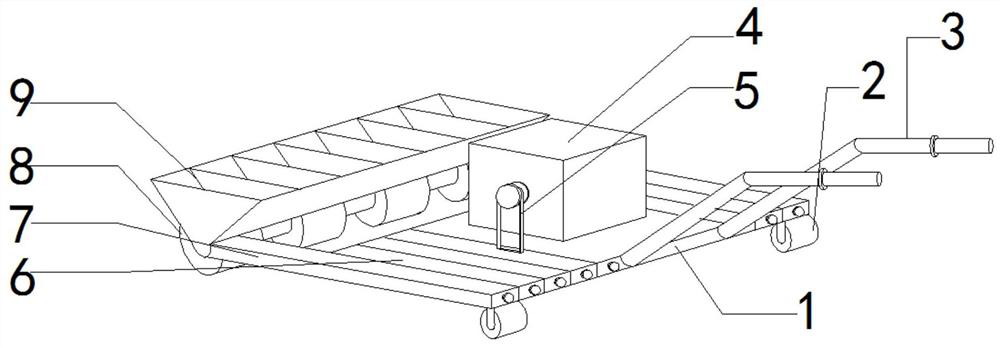

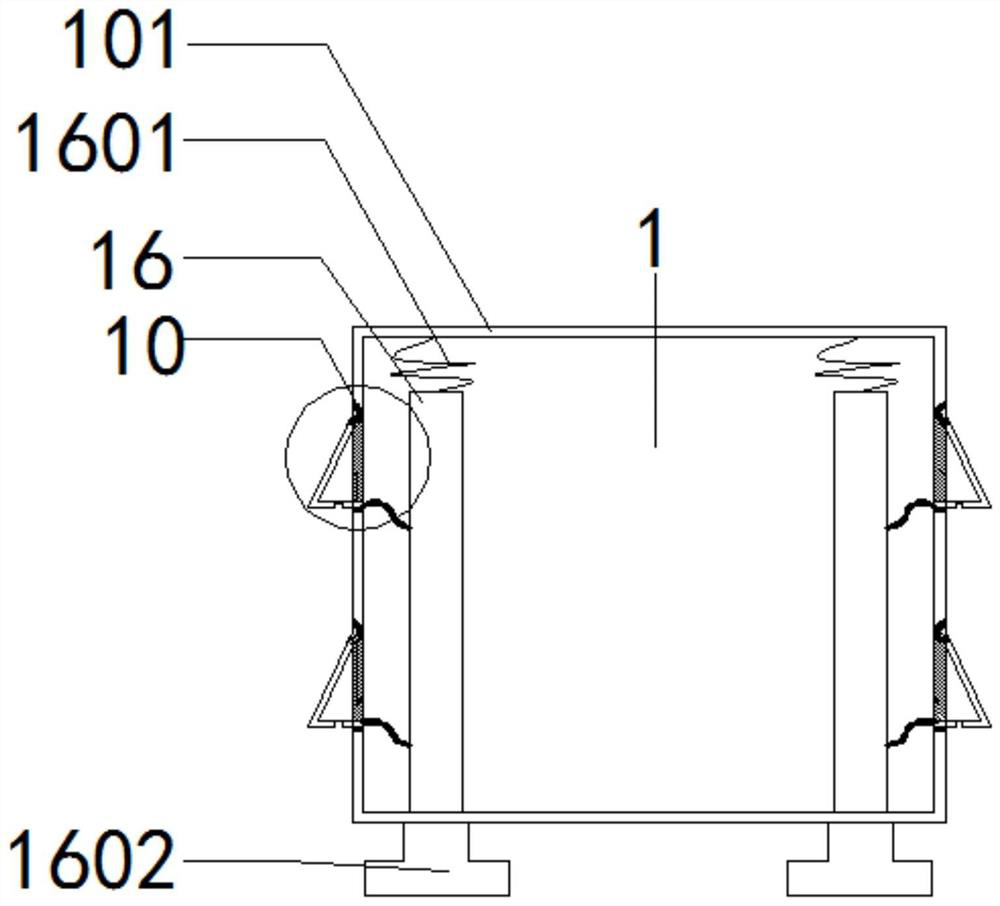

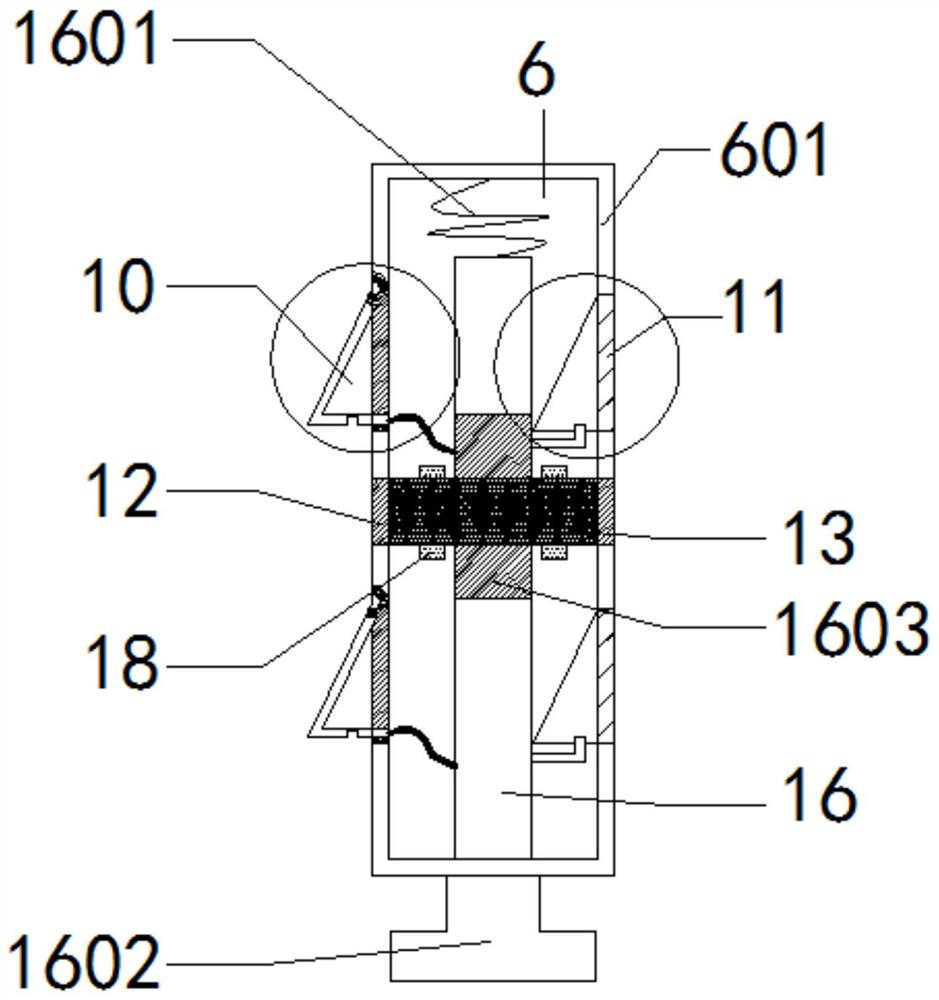

[0032] as attached figure 1 to attach Figure 11 Shown: a walk-behind seeder, including chassis 1, auxiliary wheel 2, handle 3, engine 4, belt 5, movable plate 6, connecting plate 7, seeding wheel 8, trough 9, connecting buckle 10, connecting groove 11. Drive shaft port 12, drive shaft 13, drive belt 14, connecting shaft 15, pull rod 16, seeder 17, fixed shaft 18, the top of the chassis 1 is provided with the engine 4, and the two ends of the chassis 1 are movably connected with the inner side of the movable plate 6 The outer side of the movable plate 6 is movably connected with the inner side of another movable plate 6 or the inner side of the connecting plate 7, the inner side of the connecting plate 7 is threadedly connected with one end of the connecting shaft 15, one end of the connecting shaft is threadedly connected with the connecting plate 7, and the other end is threadedly connected with the sowing wheel 8 , The top of the seeding wheel 8 is provided with a trough 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com