Manufacturing process of three-dimensional shaped automobile key case

A technology for making craftsmanship and car keys, applied in travel products, applications, clothing, etc., can solve the problems of easy disconnection, affect the appearance of products, cracked skin, etc., and achieve the effect of tight fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

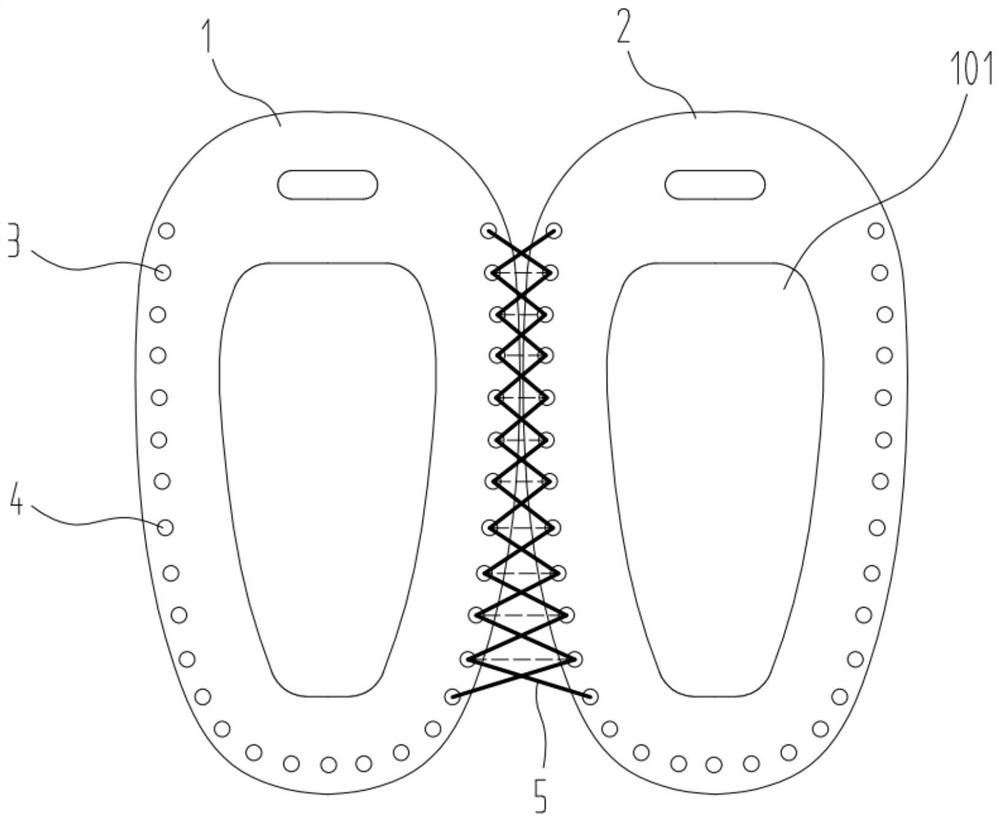

[0037] A three-dimensional stereotyped car key case manufacturing process, including the following steps:

[0038] Step 1: Half panel production;

[0039] Wrap the entire car key with masking paper, and cut the wrapped masking paper at the center line of both sides of the key to make a symmetrical front half panel and back half panel, and place them on the front according to the lines on the front and back of the car key. Drawing copper mould embossing lines on half panel and back half panel;

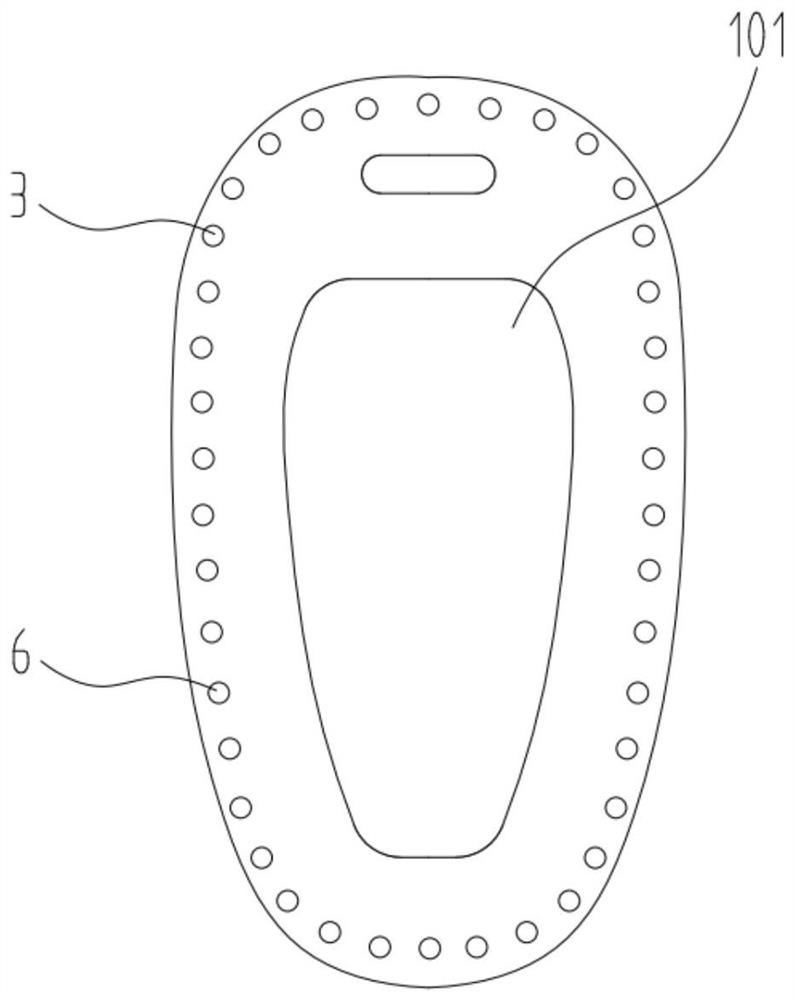

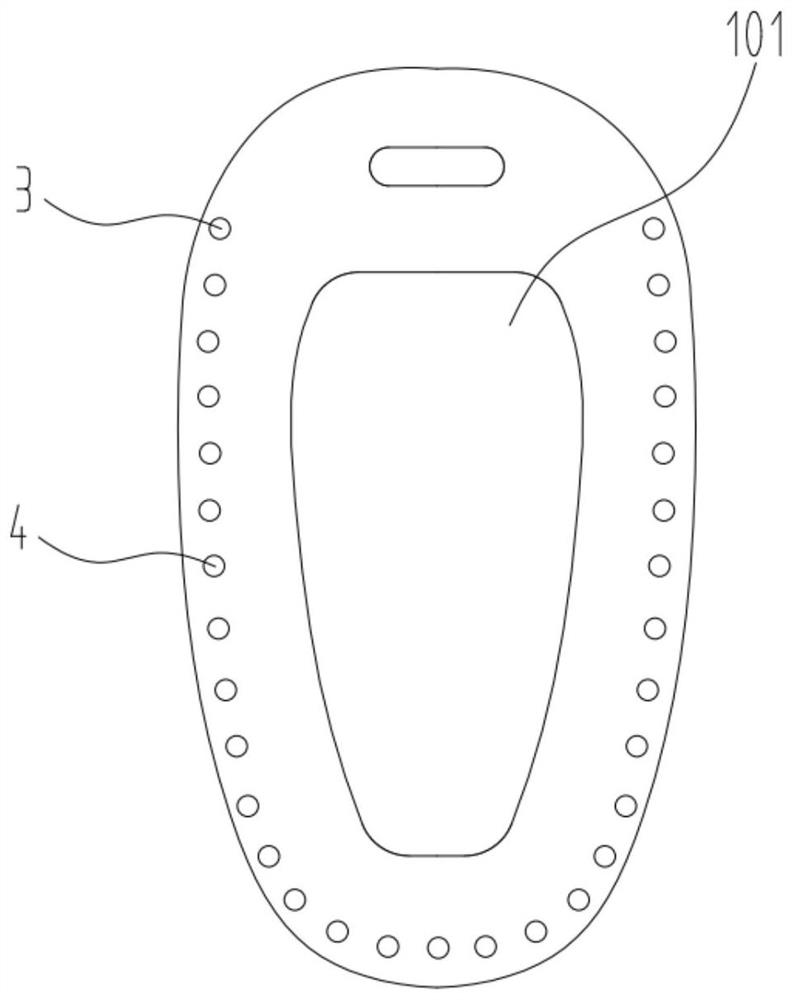

[0040] Step 2: Punching the leather case;

[0041] According to the outline dimensions of the front half panel and the back half panel prepared in step 1, a cold die is produced, and the key cover A side 1 and the key cover B side 2 are prepared by punching the raw materials through the cold die; the key cover A side and the key cover B side An opening point 3 is also provided, and the horizontal linear distance between the opening point and the highest point of the width of the key cover A su...

Embodiment 2

[0054] Step 1: Half panel production;

[0055] Wrap the entire car key with masking paper, and cut the wrapped masking paper at the center line of both sides of the key to make a symmetrical front half panel and back half panel, and place them on the front according to the lines on the front and back of the car key. Drawing copper mould embossing lines on half panel and back half panel;

[0056] Step 2: Punching the leather case;

[0057] According to the outline dimensions of the front half panel and the back half panel prepared in step 1, a cold die is produced, and the key cover A side and the key cover B side are produced by punching the raw materials through the cold die; the key cover A side and the key cover B side are also set There is an opening point, and the horizontal straight line distance between the opening point and the highest point of the width of the key cover A surface and the key cover B surface is greater than 10mm. In this way, when the key is inserted into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com