Use method of curved-surface paint brush

A paint brush and curved surface technology, which is applied to the device, brush type, application and other directions of coating liquid on the surface, can solve the problems of difficulty in controlling the amount of paint dipping, inconvenient paint dipping, and paint dipping, and easy to achieve the amount of paint dipping. Control, improve the effect of painting, reduce the effect of paint waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

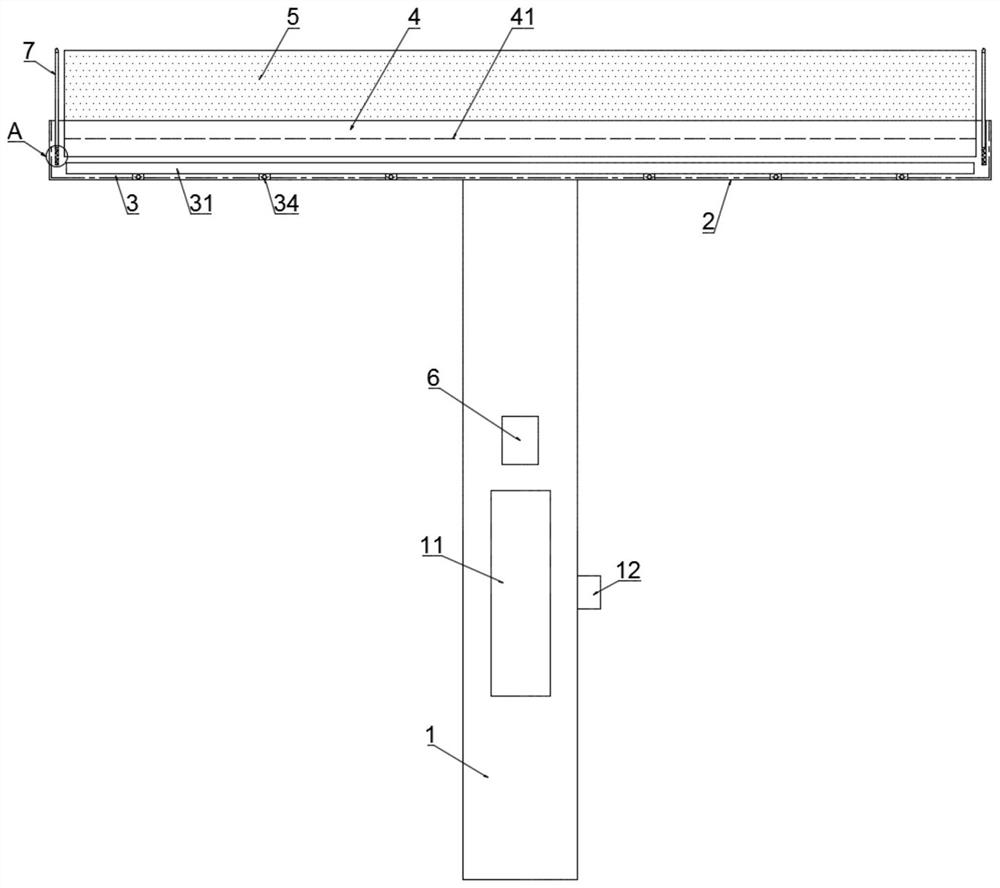

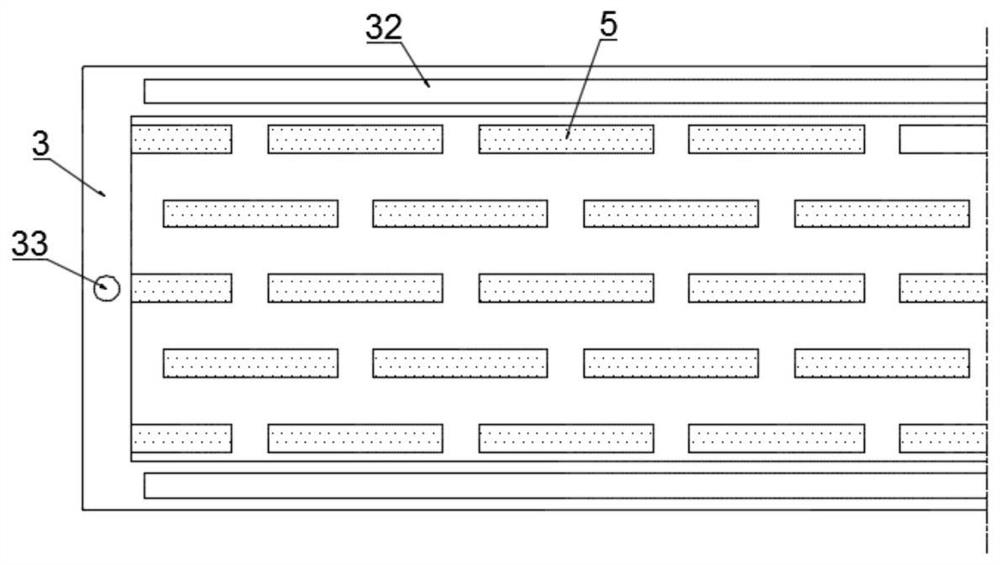

[0031] refer to Figure 1-5 , a method of using a curved surface paint brush, the specific method of use is as follows:

[0032] S1. Complete the installation and electrical connection of the handle 1, the brush head 2 and their internal devices;

[0033] S2. Use the paint brush on the brush head 2 to dip in the paint liquid, and lightly touch the middle part of the brush head 2 to the object to be painted;

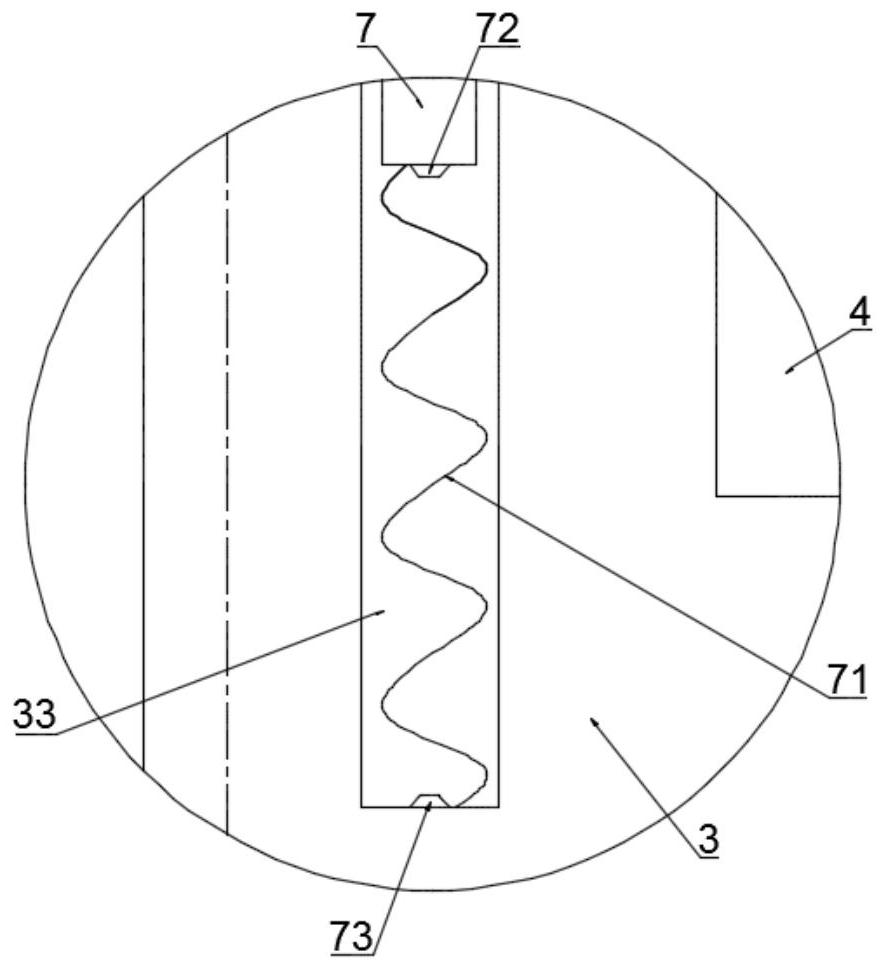

[0034] S3, the start button 12, the heating wire 41 works and generates heat, and the memory metal sheet 4 absorbs heat and changes from a straight state to a curled state;

[0035] S4, the memory metal sheet 4 drives the heat preservation shell 3 to curl up u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com