A glass tube sealing device used in a medicinal glass tube sealing assembly machine

A technology of medicinal glass and sealing device, which is applied in the directions of sealing, application and packaging with plugs, and can solve the problems of easy adhesion of dust and sticking to sealing parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

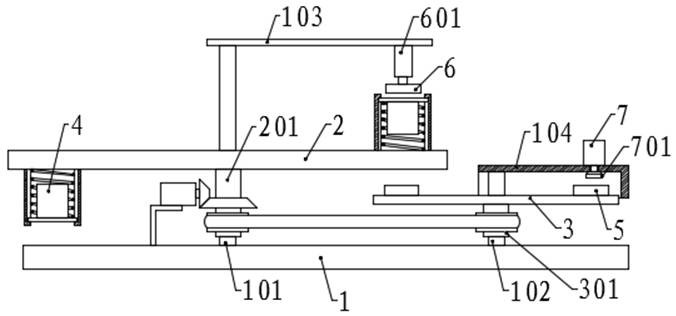

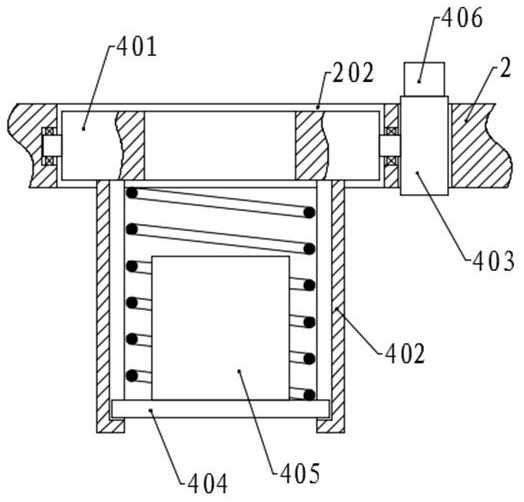

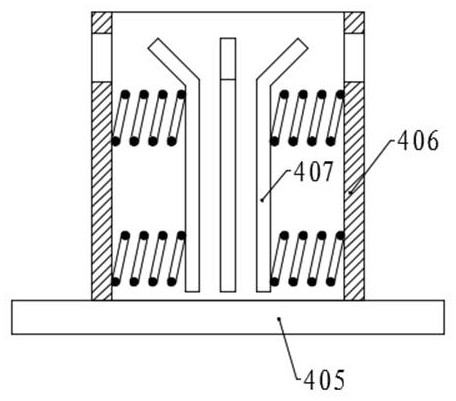

[0034]Please refer to the accompanying drawings, the present invention provides a technical solution: a glass tube sealing device for a pharmaceutical glass tube sealing assembly machine, including a base 1, a first fixed shaft 101 is fixed on the left side of the top surface of the base 1, and The right side of the face is fixed with a second fixed shaft 102, the first fixed shaft 101 is rotatably connected with a first rotating cylinder 201, the rotating cylinder on the second fixed shaft 102 is connected with a second rotating cylinder 301, and the first rotating cylinder 201 and the second rotating cylinder A driving assembly is arranged between the two rotating cylinders 301, the second rotating plate 3 is fixed on the top of the second rotating cylinder 301, the first rotating plate 2 is fixed on the top of the first rotating cylinder 201, and the right side of the first rotating plate 2 The end is located above the left end of the second rotating plate 3, and a plurality...

Embodiment 2

[0045] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the top end of the second fixed shaft 102 protrudes from the second rotating plate 3 and is fixed with a second fixed plate 104, the top surface of the second fixed plate 104 is right The jet pump 7 is fixed on the side, and the nozzle 701 is fixed on the right side of the bottom surface, and the nozzle 701 is connected with the jet pump 7 .

[0046] When the first rotating plate 2 drives the sealing to fix the sealing position, the second roller 503 first contacts the first arc surface on the second cam 302, and the sealing piece is positioned through the clamping block 501 and the slot, and then rotates to the nozzle 701 At the top surface of the sealing part, the blowing pump 7 and the nozzle 701 are used to blow off the dust and debris that may exist on the sealing part, so as to improve the subsequent sealing quality; Sterilization lamps and other structures are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com