Road isolation fence with built-in coordinated energy consumption combined structure

A combined structure and barrier technology, which is applied in the direction of roads, roads, road safety devices, etc., can solve the problem of limited deformation capacity and energy absorption capacity of guardrails, limited deformation capacity and energy absorption capacity, and secondary safety problems of vehicles and crew members. Injury and other problems, to achieve the effect of convenient industrial disassembly, good connection performance, and improve the safety performance of the car body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

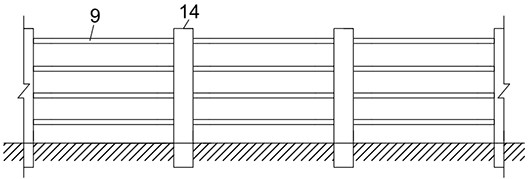

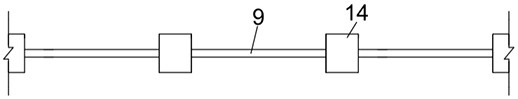

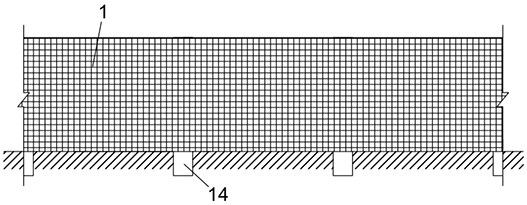

[0024] Example: such as Figure 1~Figure 9 As shown, the present invention has a built-in coordinated energy-dissipating combined structure road barrier, including crash pads 1, energy-dissipating connecting plates 2, energy-dissipating substrates 3, shock-absorbing buffer materials 4, connectors 5, back plates 6, coordination Energy-dissipating combined structure 7, connecting plate 8, connecting beam 9, energy-dissipating soft steel plate A10, energy-dissipating soft steel plate B11, high-strength fixed hinge 12, ordinary fixed hinge 13, vertical connection fixed pile 14, hinge coordinated connection elastic rod 15, A number of connecting crossbeams 9 are arranged on the road separation fence with a built-in coordinated energy consumption combination structure, and the left and right sides of the connecting crossbeam 9 are fixed with vertical connection fixing piles 14. The backplane 6 and the connecting crossbeam 9 are fixed; on the outside of the backplane 6, several coord...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap