Comprehensive pipe rack structure

A technology of integrated pipe gallery and pipe gallery, which is applied in the direction of underwater structures, infrastructure engineering, water conservancy projects, etc., can solve the problems of increasing natural gas encountering sparks, natural gas diffusion, and large safety hazards, so as to increase fire prevention and reduce Destroy and reduce the effect of surface accident losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

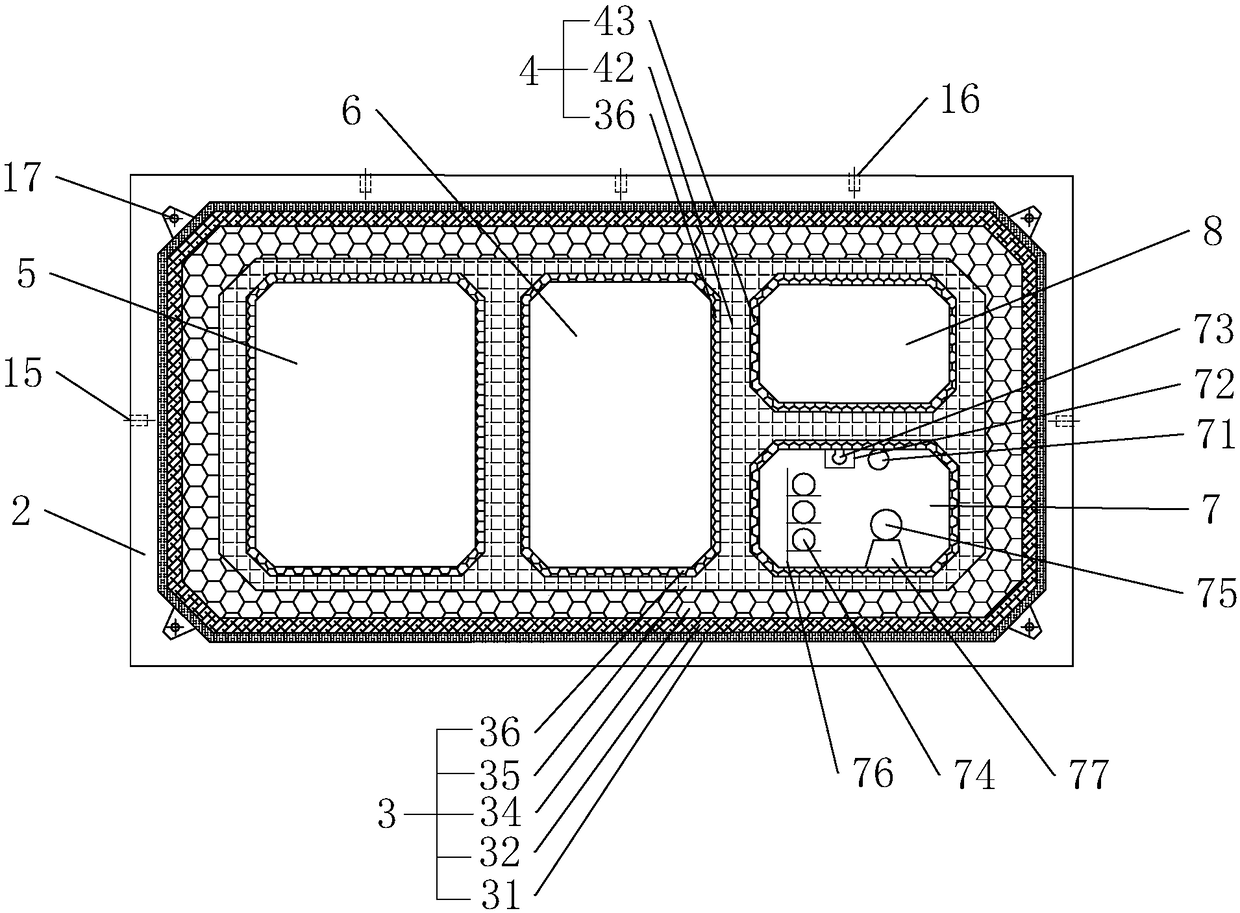

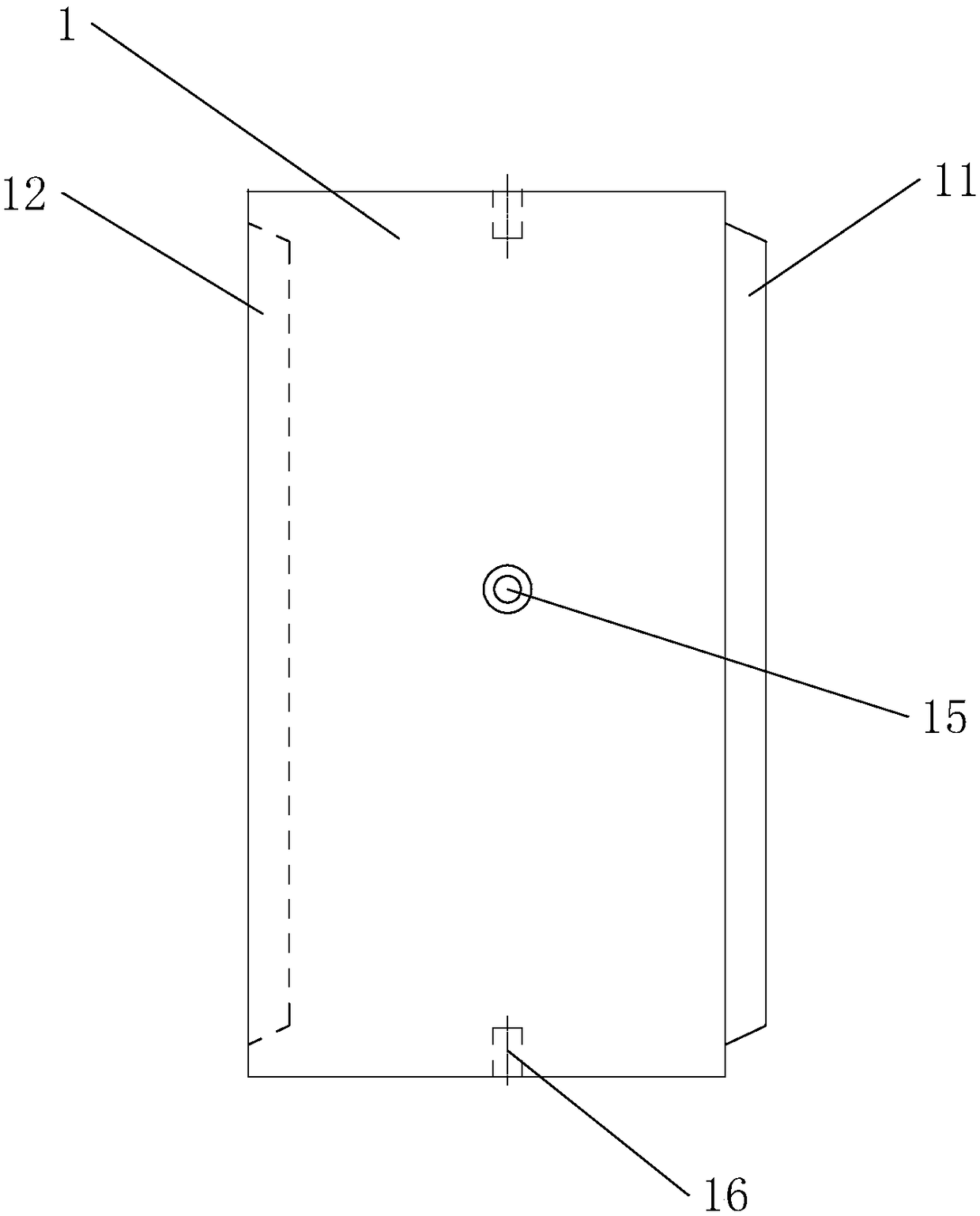

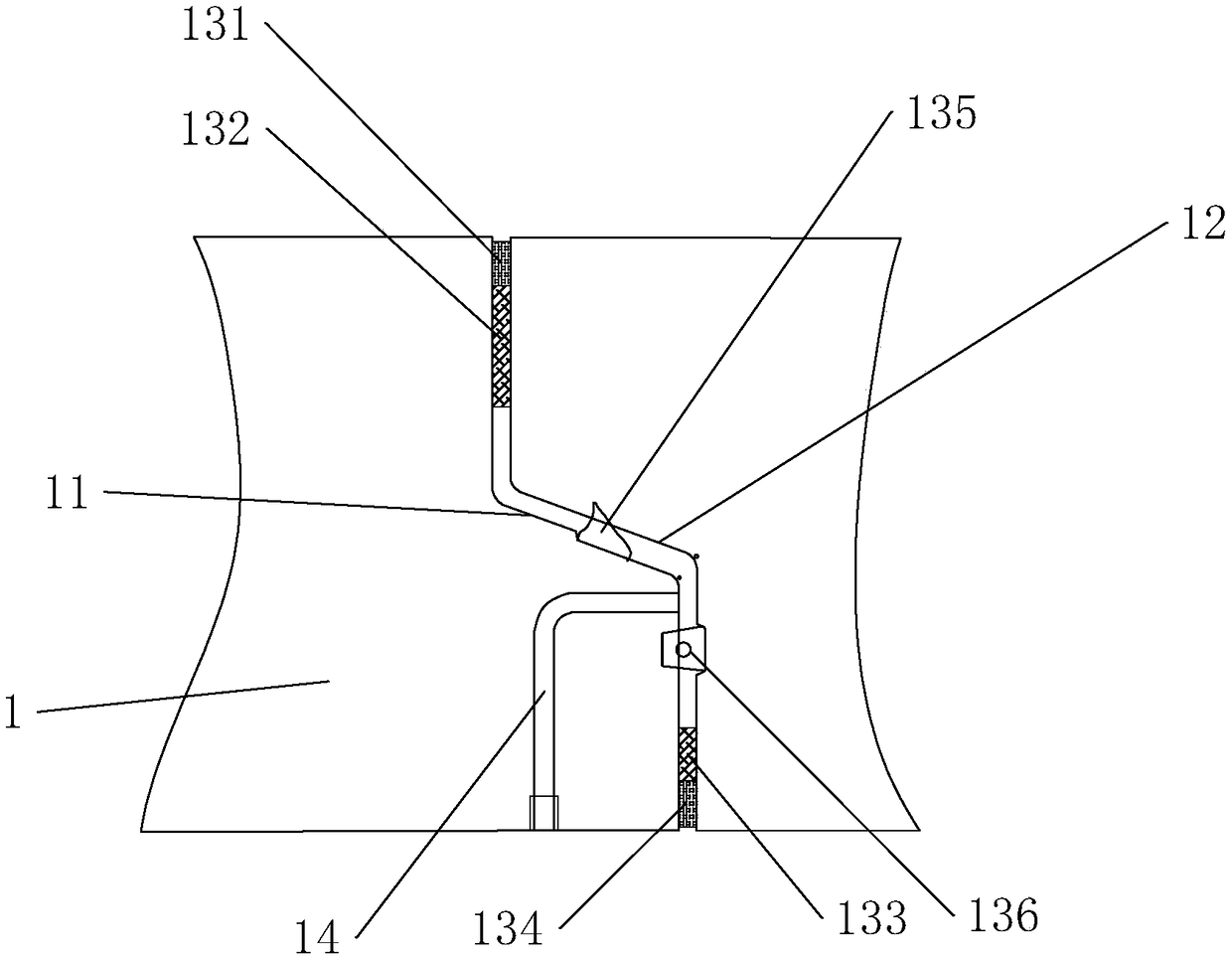

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0036] A comprehensive pipe corridor structure, such as figure 1 and figure 2 As shown, it is spliced by a plurality of end-to-end prefabricated sections 1, each prefabricated section 1 includes the main body of the pipe gallery 2, and the main body of the pipe gallery 2 is arranged side by side in turn with a comprehensive cabin 5, a rainwater cabin 6, a natural gas cabin 7, and a natural gas cabin 7 just above is provided with sewage tank 8. The first fireproof sealing wall 3 is set between the rainwater tank 6 and the natural gas tank 7 and the pipe gallery main body 2, and the second fireproof sealing wall 4 is set between the rainwater tank 6 and the natural gas tank 7, and the natural gas tank 7 and the sewage tank 8 .

[0037] The first fireproof sealing wall 3 is arranged successively from the pipe gallery main body 2 to the rainwater tank 6 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com