Steel wire rope looseness and breakage detection mechanism for mechanical stereo garage

A technology of a three-dimensional garage and a detection mechanism, which is applied in the direction of using mechanical devices to transmit sensing components, buildings where cars are parked, and building types, etc., which can solve the problems of untimely detection of wire rope loosening detection methods, high detection costs, and low detection efficiency. problem, achieve the effect of saving time and manpower, high detection efficiency and low detection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

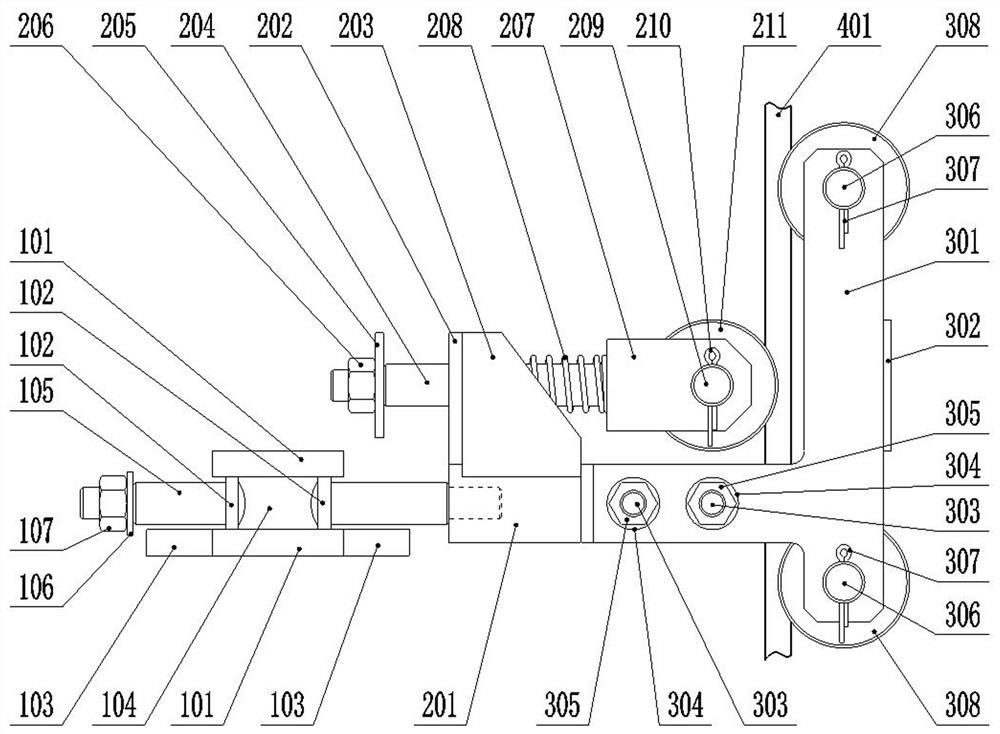

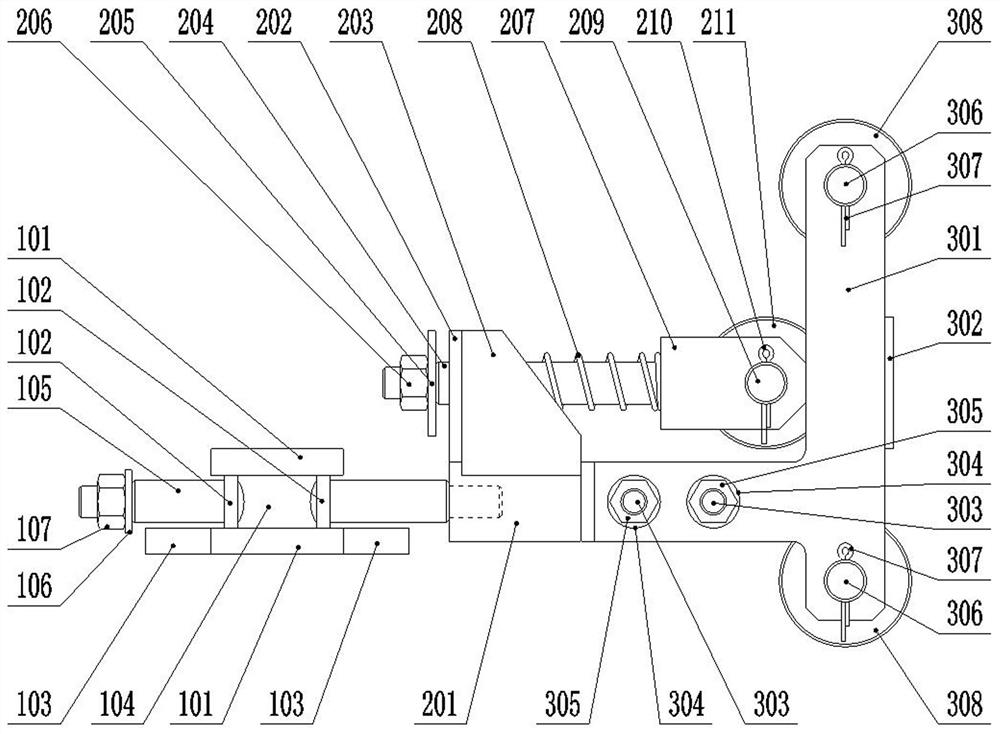

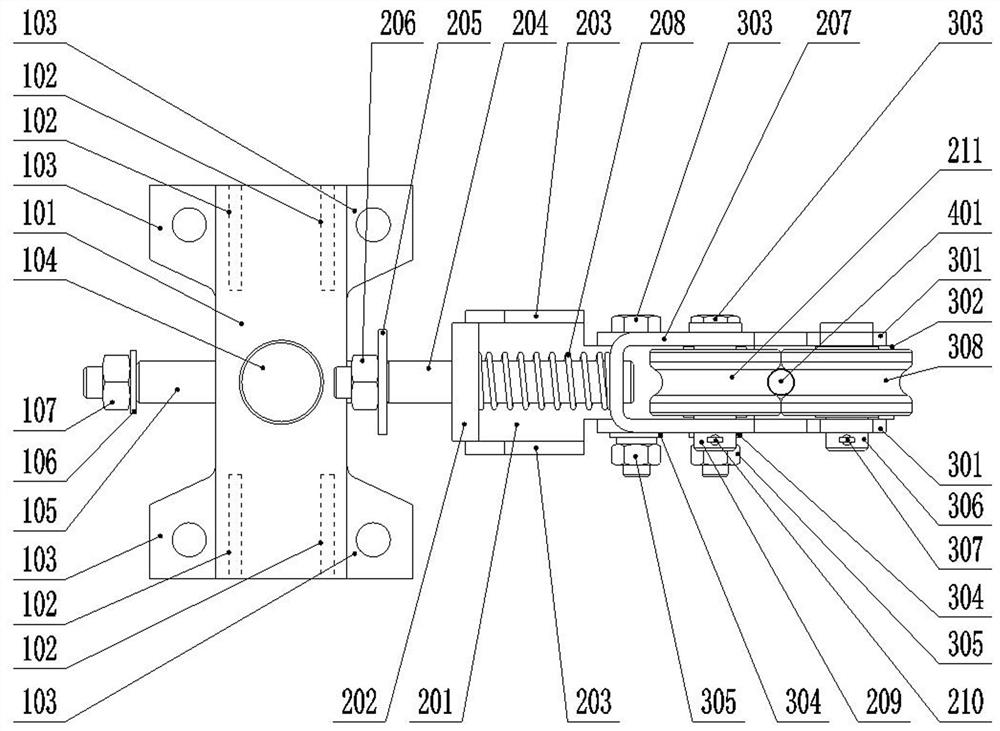

[0035] A wire rope looseness detection mechanism for a mechanical three-dimensional garage, comprising a mounting seat, a rope pressing mechanism, and a supporting rope mechanism;

[0036] The mounting seat includes two vertical strip-shaped flat plates 101, four vertical strip-shaped vertical plates 102, four lug plates 103, a pivot shaft 104, a first support shaft 105, a limit washer 106, and a limit nut 107;

[0037] The two vertical strip-shaped flat plates 101 are facing up and down, and the center of the plate surface of the two vertical strip-shaped flat plates 101 is respectively provided with a first assembly hole; The four corners of the lower plate surface of the strip-shaped plate 101 are fixed; the lower end surfaces of the four vertical strip-shaped vertical plates 102 are respectively fixed to the four corners of the upper plate surface of the second vertical strip-shaped plate 101; The two ends of the left end surface and the two ends of the right end surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com