Motor operation detection system and method

A detection system and operating frequency technology, applied in the direction of motor generator testing, measuring electricity, measuring devices, etc., can solve the problems of waste and missed inspection of human resources, and achieve the effect of avoiding missed inspection and avoiding human resource waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

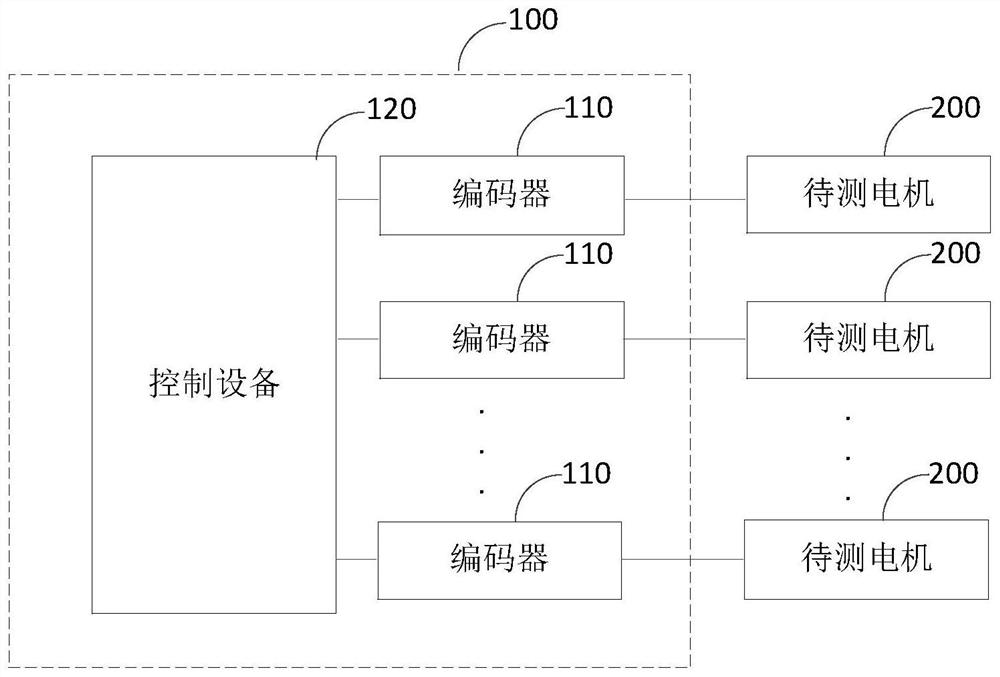

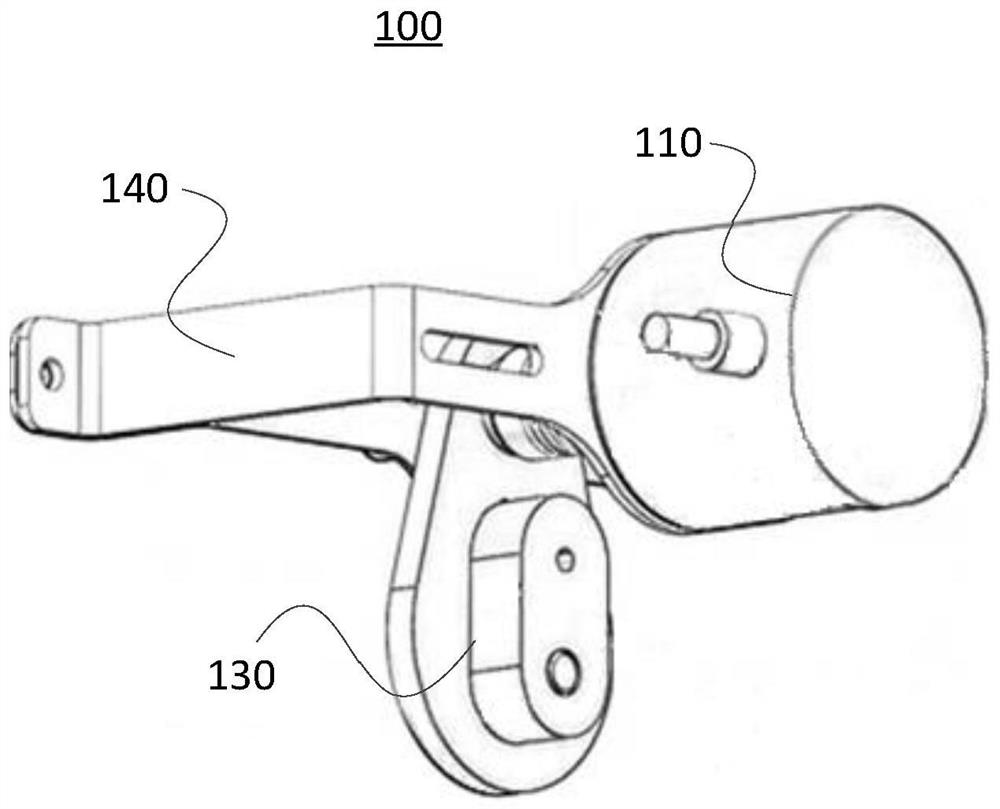

[0033] Please refer to figure 1 and figure 2 , the present application provides a motor operation detection system 100 for detecting whether the motor 200 to be tested is abnormal, and the motor operation detection system 100 can detect one or more motors 200 to be tested.

[0034] The motor running detection system 100 includes an encoder 110 and a control device 120 , and the encoder 110 is electrically connected to the control device 120 . The encoder 110 is arranged on the rotating shaft of the motor to be tested 200, and can rotate with the rotating shaft of the motor to be tested 200 when the motor to be tested 200 is running, and is used to detect the operation of the motor to be tested 200 when it is running. parameters, the control device 120 is used to obtain the operating parameters detected by the encoder 110, and determine whether the operating parameters meet the preset conditions, and confirm that the motor under test 200 is tested when the operating parameter...

Embodiment 2

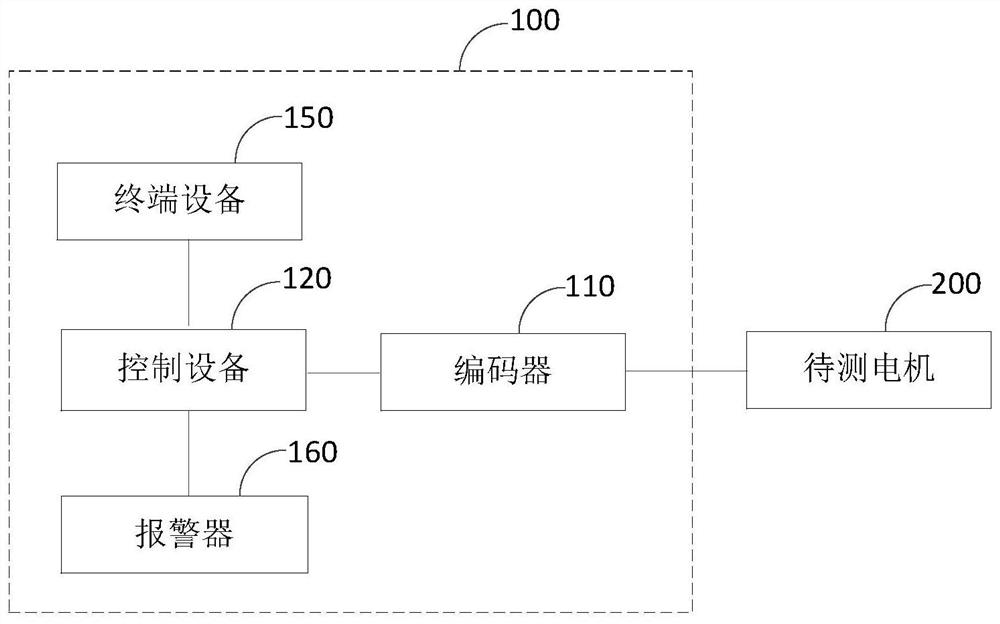

[0065] see Figure 4 , this embodiment also provides a motor operation detection method, the motor operation detection method can be applied to the above-mentioned motor operation detection system 100, and the following steps are performed when the motor operation detection method is applied to the above-mentioned motor operation detection system 100 :

[0066] Step S110 : The encoder 110 detects the operating parameters of the motor under test 200 when the motor under test 200 is running and sends the operating parameters to the control device 120 when the motor under test 200 rotates along with the rotation shaft of the motor under test 200 .

[0067] Step S120: When the control device 120 receives the operation parameter sent by the encoder 110, it judges whether the operation parameter meets the preset condition, and when the operation parameter does not meet the preset condition, confirms that the waiting parameter is The detection motor 200 is abnormal and an alarm sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com