An intelligent monitoring method and system for the operation status of process production equipment

A technology for operating status and intelligent monitoring, which is applied in complex mathematical operations, instruments, and other database retrieval directions. Generalization ability, eliminating the effects of changes in external conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The following is a detailed description of the embodiments of the present invention. This embodiment is carried out based on the technical solution of the present invention, and provides detailed implementation methods and specific operation processes to further explain the technical solution of the present invention.

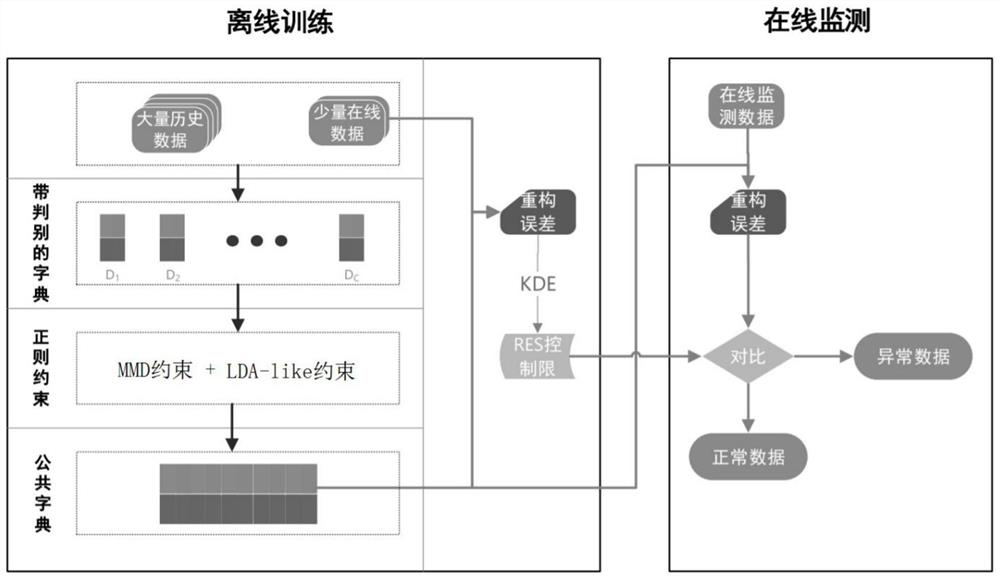

[0076] this reference figure 1 As shown, the embodiment applies the intelligent monitoring method of the present invention to the intelligent monitoring of the operating state of the continuous stirring tank heater, including the following steps:

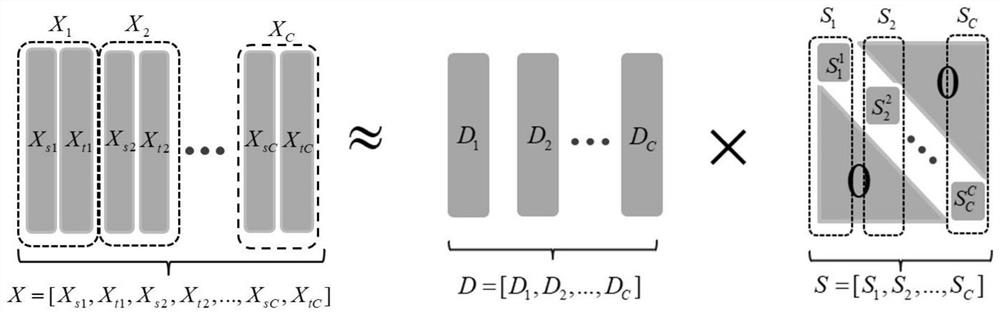

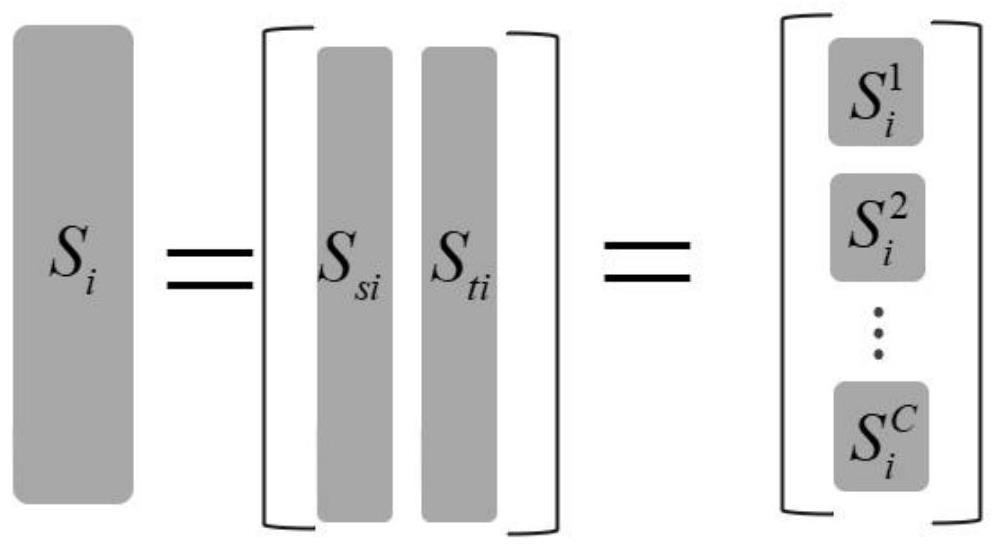

[0077] Step 1: Obtain the historical data obtained from the operation of the continuous stirred tank heater CSTH1 in two modes as the source domain data X s =[X s1,X s2 ,...,X si ,...,X sC ], since there are only two modes in this embodiment, C=2, and X s1 is the source domain historical data corresponding to one mode, X s2 is the source domain historical data corresponding to mode 2;

[0078] Obtain th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com