Excessive-growing tobacco leaf curing method

A curing method and tobacco leaf technology are applied in the directions of tobacco, tobacco preparation, application, etc., and can solve the problems of easy curing black, yellowing and drying relationship are difficult to be carried out simultaneously, and leggy tobacco leaves are difficult to be cured, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

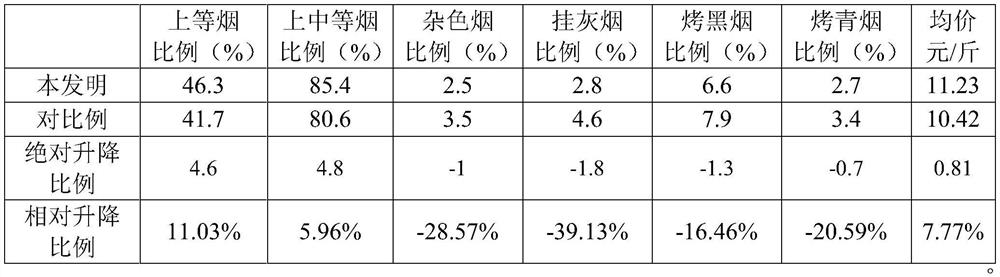

Examples

Embodiment 1

[0033] The roasting method of long tobacco leaves is used for the roasting of long tobacco leaves. The long tobacco leaves refer to the tobacco leaves with hypertrophic leaves, thick stalks, and low dry matter accumulation caused by factors such as excessive application of nitrogen fertilizer, tobacco plant nutrition disorders, and poor field management.

[0034] 1. The collection standard of long tobacco leaves

[0035] When harvesting long tobacco leaves, wait patiently for them to mature and yellow to prevent yellowing and dehydration during baking. But it should not be over-cooked to prevent it from being ash or blackened. It should be harvested when the tip of the leaf is obviously yellowish, and the leaf surface has yellow spots.

[0036] 2. Requirements for weaving long tobacco leaves

[0037] The poles must be sorted to ensure that the poles are of the same quality. According to the 1.5-meter long standard rod, 45-55 pinches of tobacco per rod, that is, 90-110 pieces, each p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com