Flue-cured tobacco management and baking method based on betaine application for relieving gray smoke

A management method and technology of betaine, applied in the fields of tobacco, application, and preparation of tobacco, to achieve the effect of promoting the absorption of tobacco plants, simple operation, and convenient field operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

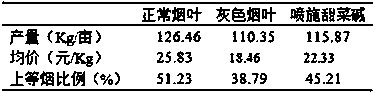

Examples

Embodiment 1

[0078] A flue-cured tobacco management method based on betaine application to alleviate gray smoke, comprising the following steps:

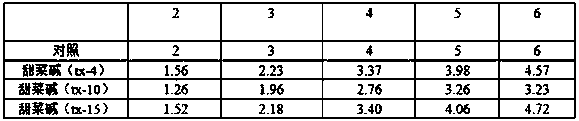

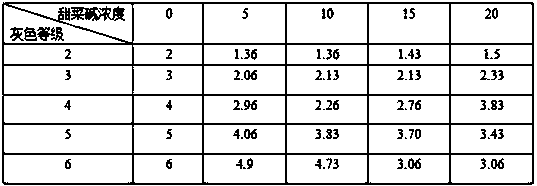

[0079] 1) Tobacco leaf gray grade identification and one-time spraying: Grade identification is carried out on the tobacco plants with gray smoke, and the disease degree of gray flue-cured tobacco is divided into six levels as follows:

[0080] Grade 0: The whole leaf is disease-free;

[0081] Grade 1: sporadically distributed gray-black spots on the main vein or branch veins, not exceeding 5% of the leaf area;

[0082] Grade 2: Gray black spots occupy 5%-15% of the leaf area;

[0083] Grade 3: Gray black spots occupy 15%-30% of the leaf area;

[0084] Grade 4: Gray black spots account for 30%-45% of the leaf area;

[0085] Grade 5: Gray black spots account for more than 45% of the leaf area;

[0086] Grade 6: gray-black spots occupy more than 45% of the leaf area, and gray-black spots appear on the petiole and spread to the stem;

[0087] ...

Embodiment 2

[0099] A flue-cured tobacco management method based on betaine application to alleviate gray smoke, comprising the following steps:

[0100] 1) Tobacco leaf gray grade identification and one-time spraying: Grade identification is carried out on the tobacco plants with gray smoke, and the disease degree of gray flue-cured tobacco is divided into six levels as follows:

[0101] Grade 0: The whole leaf is disease-free;

[0102] Grade 1: sporadically distributed gray-black spots on the main vein or branch veins, not exceeding 5% of the leaf area;

[0103] Grade 2: Gray black spots occupy 5%-15% of the leaf area;

[0104] Grade 3: Gray black spots occupy 15%-30% of the leaf area;

[0105] Grade 4: Gray black spots account for 30%-45% of the leaf area;

[0106] Grade 5: Gray black spots account for more than 45% of the leaf area;

[0107] Grade 6: gray-black spots occupy more than 45% of the leaf area, and gray-black spots appear on the petiole and spread to the stem;

[0108] ...

Embodiment 3

[0120] A flue-cured tobacco management method based on betaine application to alleviate gray smoke, comprising the following steps:

[0121] 1) Tobacco leaf gray grade identification and one-time spraying: Grade identification is carried out on the tobacco plants with gray smoke, and the disease degree of gray flue-cured tobacco is divided into six levels as follows:

[0122] Grade 0: The whole leaf is disease-free;

[0123] Grade 1: sporadically distributed gray-black spots on the main vein or branch veins, not exceeding 5% of the leaf area;

[0124] Grade 2: Gray black spots occupy 5%-15% of the leaf area;

[0125] Grade 3: Gray black spots occupy 15%-30% of the leaf area;

[0126] Grade 4: Gray black spots account for 30%-45% of the leaf area;

[0127] Grade 5: Gray black spots account for more than 45% of the leaf area;

[0128] Grade 6: gray-black spots occupy more than 45% of the leaf area, and gray-black spots appear on the petiole and spread to the stem;

[0129] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com