a sedimentation tank

A sedimentation tank and pool body technology, applied in the field of sedimentation tanks, can solve the problems such as the inability to continue working after cleaning the sludge, and the decline in work efficiency, so as to achieve the effect of improving practicability and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

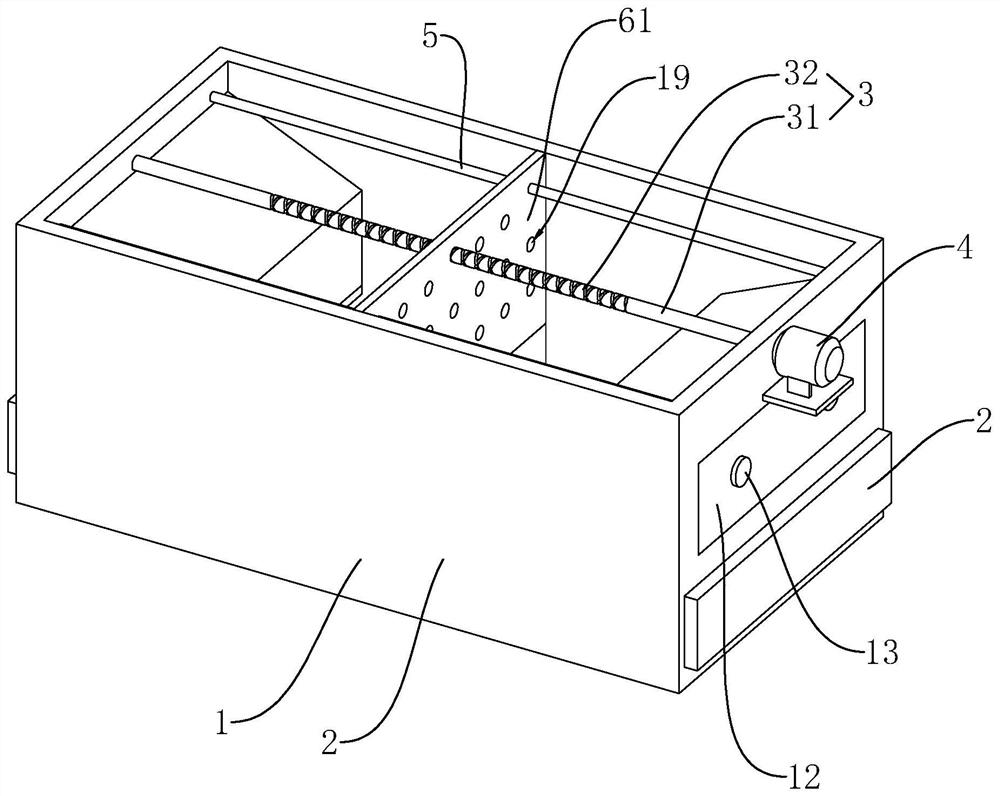

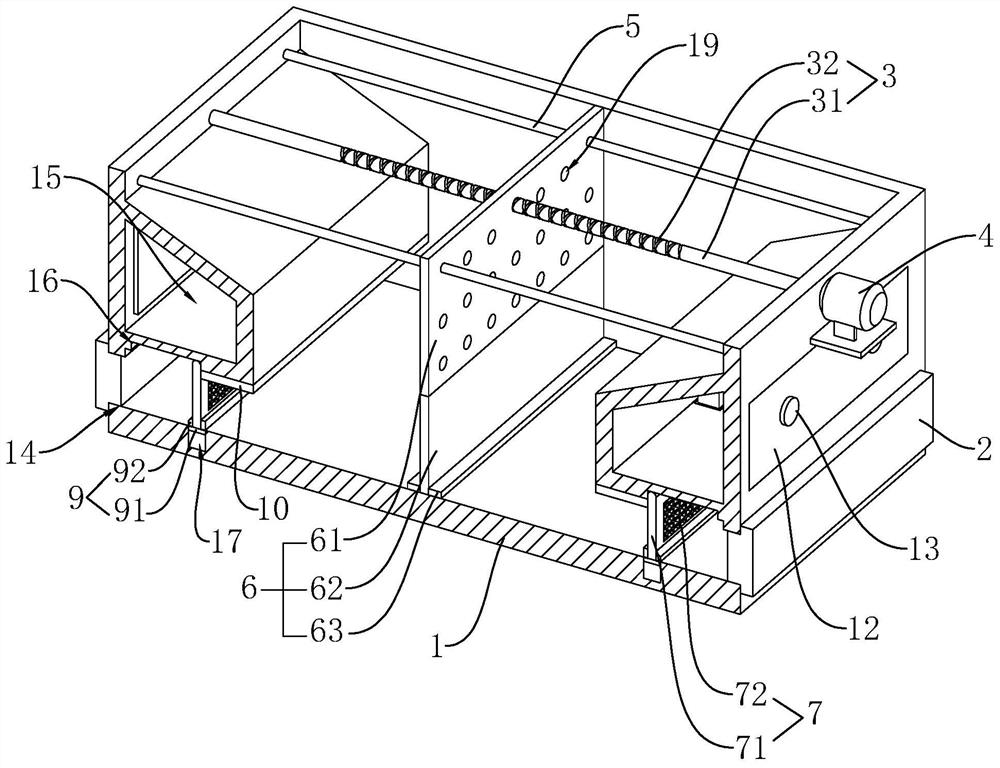

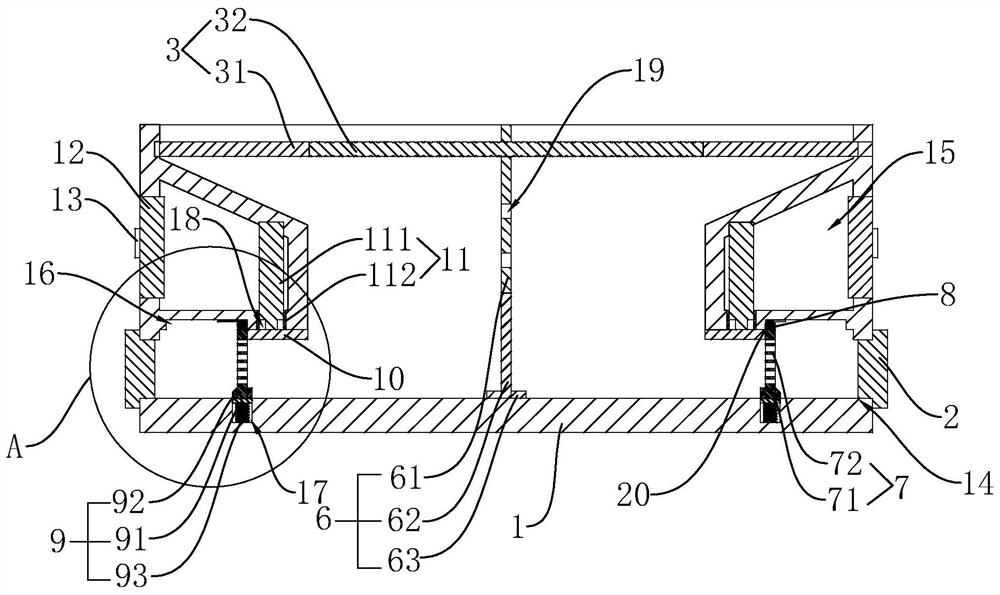

[0037] refer to figure 1 with image 3 , is a kind of sedimentation tank disclosed by the present invention, comprising a tank body 1, two opposite side walls of the tank body 1 are respectively penetrated with mud cleaning holes 14 communicating with the inside of the tank body 1, and the outer side walls of the tank body 1 are detachably connected There is a cover plate 2 for closing or opening the mud cleaning hole 14.

[0038] refer to figure 2 with image 3 A two-way screw rod 3 is rotatably connected between two opposite inner walls of the pool body 1, one end of the two-way screw rod 3 penetrates to the outside of the pool body 1, and a motor connected to the end of the two-way screw rod 3 is fixedly connected to the outer wall of the pool body 1 4. The two opposite inner walls of the pool body 1 are respectively fixedly connected with guide rods...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com