Screwdriver head and clamping piece

A technology of clamping parts and bits, which is applied in the direction of wrench, wrench, screwdriver, etc., can solve problems such as loosening, affecting the use effect, and unstable fixation, and achieves the effects of convenient processing, strong clamping effect, and high fixing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

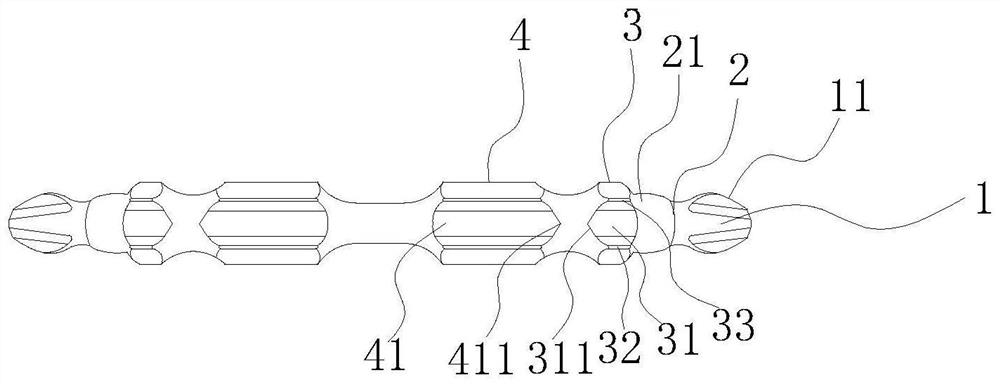

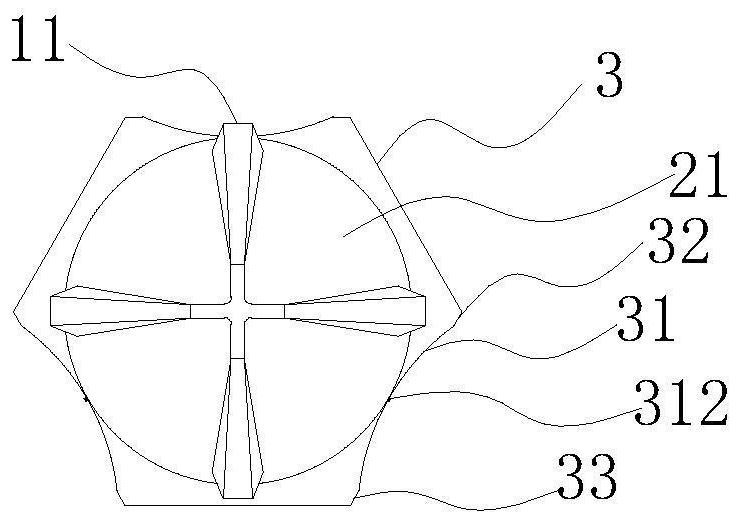

[0038] Refer to attached Figure 1-2 As shown, a bit includes a first head 1, a first connecting part 2, a first fixing part 3 and a second fixing part 4, and the first head 1 is connected to the first fixing part 3 through the first connecting part 2. Connection, the first fixing part 3 is connected with the second fixing part 4 .

[0039] The first head 1 can be in the shape of a straight line, a cross or a quincunx, and this embodiment only takes the cross shape as an example. Four wing teeth 11 are arranged on the first head 1, and the four wing teeth 11 are connected to form a cross shape. The side of the wing tooth 11 is arched, specifically a parabolic shape, where the parabolic equation satisfies Y=0.75X^2+0.17, and it should be noted here that the range of X is (-1,1), ensuring that the wing tooth 11, thereby controlling the overall center of gravity and stability of the bit, and the height of the arch is limited, so that the side walls of the wing teeth 11 fit bett...

Embodiment 2

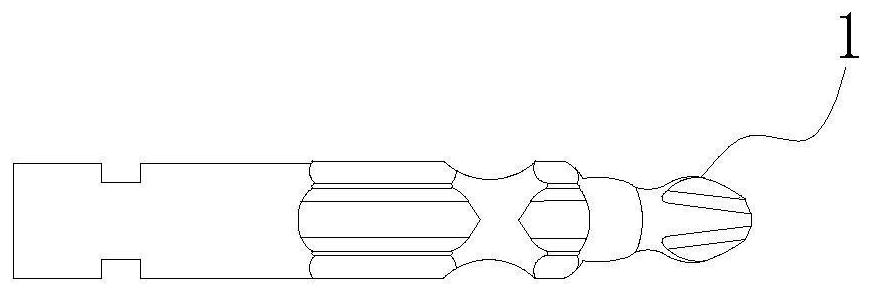

[0052] Refer to attached image 3 As shown, the difference between Embodiment 2 and Embodiment 1 is that the bit in this embodiment is set with a single head, that is, only one first head 1 is set.

Embodiment 3

[0054] Refer to attached Figure 4-7 As shown, a clamping piece includes a bit and a main body 5. The structure of a bit has been described in detail in Embodiment 1, so no further description is given here.

[0055] The main body 5 is provided with a first part 6 and a second part 7 , the second part 7 is sheathed on the first part 6 and the two are in a rotational connection, specifically a screw connection here. The size of the second part 7 is larger than the size of the first part 6 . The first component 6 is provided with a through hole 61 , and the through hole 61 is integrally set through the first component 6 . The second component 7 is provided with three clamping parts 71, and the three clamping parts 71 are distributed in a circular array and have the same shape. The three clamping parts 71 penetrate into the through hole 61 and move axially along the inner wall of the through hole 61. The tops of the three clamping parts 71 form a clamping opening 711 for the ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com