Pre-twisted fitting for aerial optical cable

An overhead optical cable, pre-twisted technology, used in optical fiber/cable installation, optics, light guide, etc., can solve the problems of inability to stretch force, buffer unloading force and energy absorption, twisted wire pulling deformation, poor tensile resistance, etc. Practical and convenient, the effect of eliminating stress concentration and avoiding fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

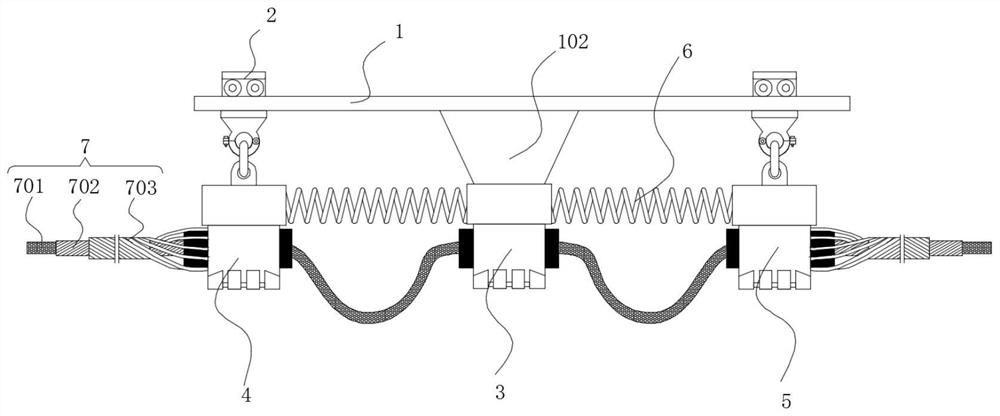

[0029] refer to Figure 1-3 with Figure 8 , including a mounting bracket 1, a movable component 2, a support component 3, a left fixed component 4, a right fixed component 5 and an optical cable component 7, the support component 3 is fixedly arranged in the middle of the mounting bracket 1, and the movable component 2 is provided with two groups and installed movably On the mounting brackets 1 on both sides of the support member 3, the left fixed assembly 4 and the right fixed assembly 5 are respectively connected to the movable assemblies 2 on both sides, and the optical cable assembly 7 is fixed through the left fixed assembly 4, the support member 3 and the right fixed assembly 5 Connection, the support member 3 is fixedly connected with the left fixing component 4 and the right fixing component 5 through rigid springs 6 respectively.

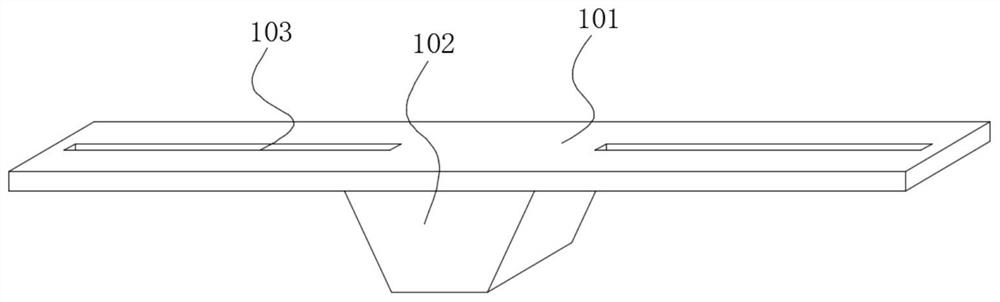

[0030] The mounting bracket 1 includes a mounting plate 101 and a supporting boss 102. The supporting boss 102 is integrally formed in t...

Embodiment 2

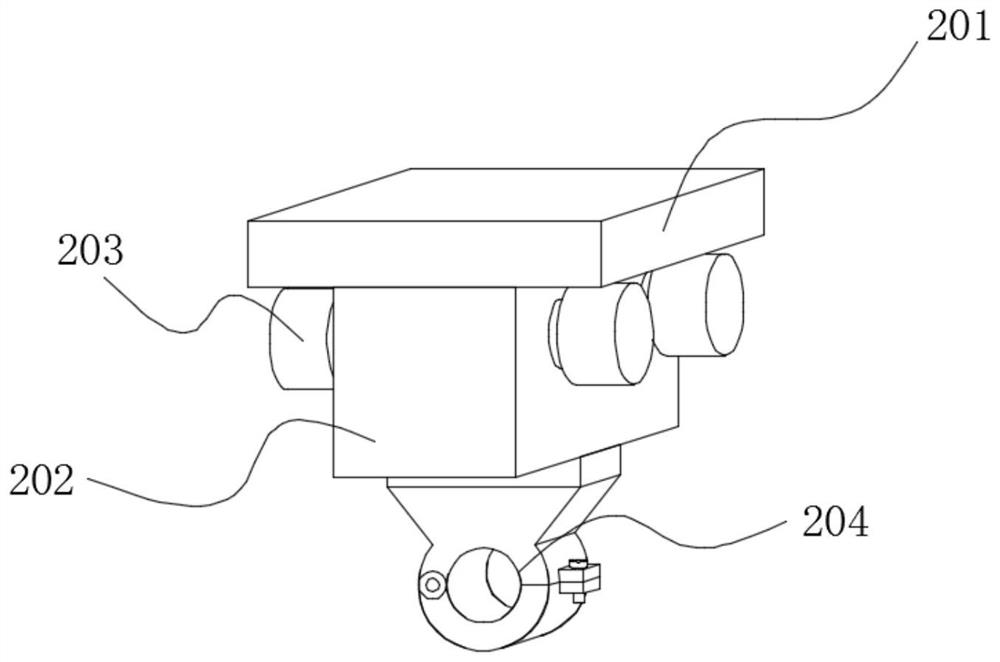

[0036] refer to Figure 4-8 The difference between this embodiment and the embodiment is that the structure of the movable assembly 2 is different. In this embodiment, the mounting bracket 1 includes a mounting plate 101 and a supporting boss 102, and the supporting boss 102 is integrally formed in the middle of the mounting plate 101. The two ends of mounting plate 101 are provided with rotation slotted hole 104, and two groups of movable assemblies 2 are installed in rotation slotted hole 104 places and are movably connected with left fixed assembly 4, right fixed assembly 5 by elastic telescoping rod 8.

[0037]The movable assembly 2 comprises a limiting disc 207, a rotating shaft 205 and a support ring 206, the rotating shaft 205 is integrally formed on the lower side of the limiting disc 207, the lower end of the rotating shaft 205 is integrally formed with a supporting ring 206, and the rotating shaft 205 The support ring 206 passing through the sliding groove 103 and it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com