Self-luminous glass

A self-luminous, glass technology, used in illuminated signs, instruments, display devices, etc., can solve the problems of difficult maintenance and high cost of luminous glass, and achieve the effects of convenient maintenance, simple structure and improved aesthetics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

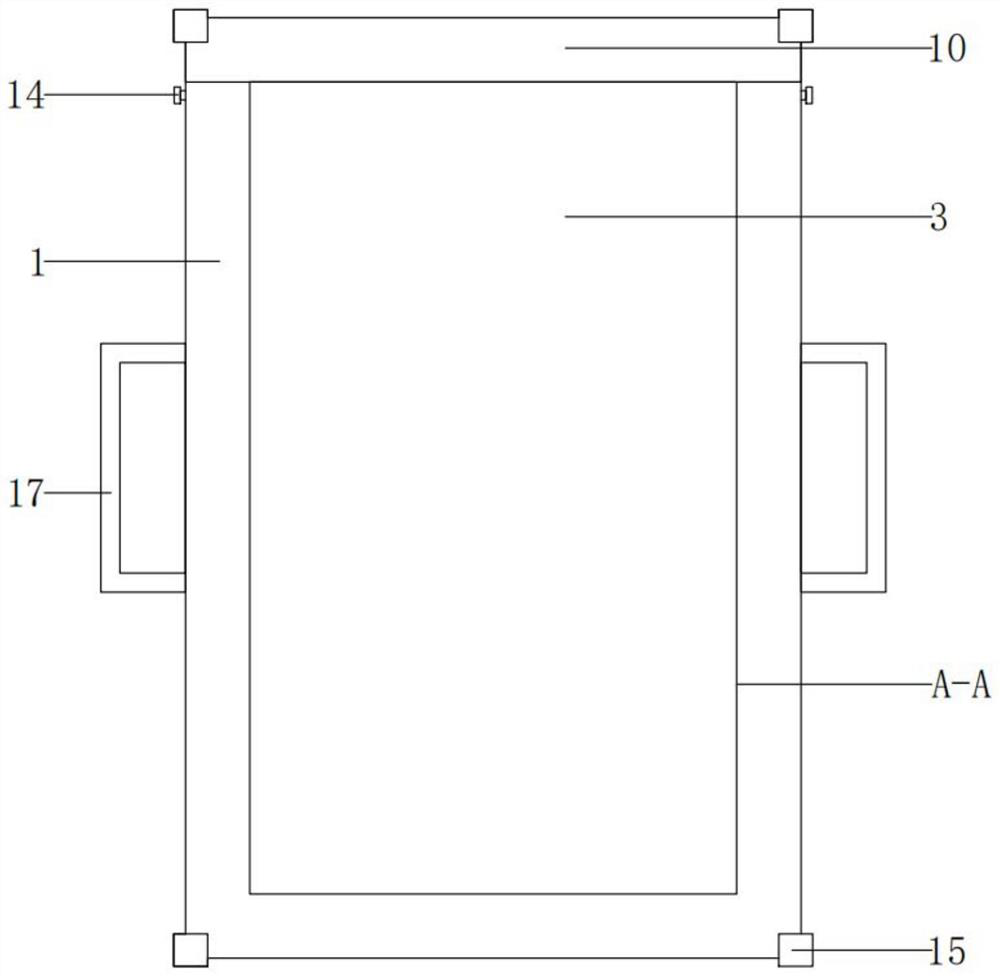

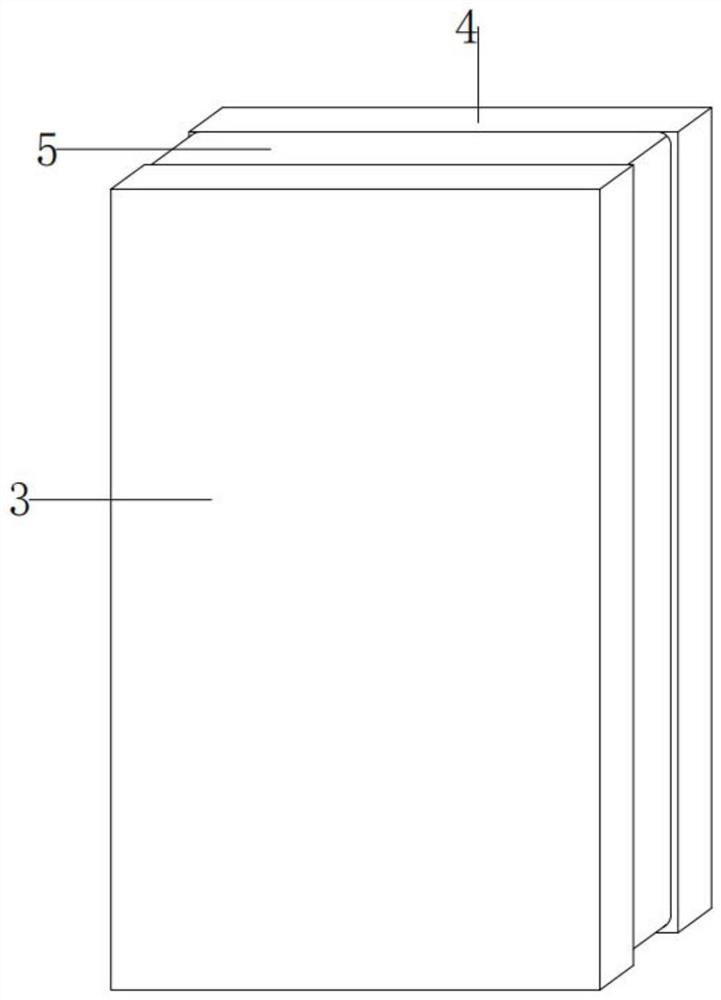

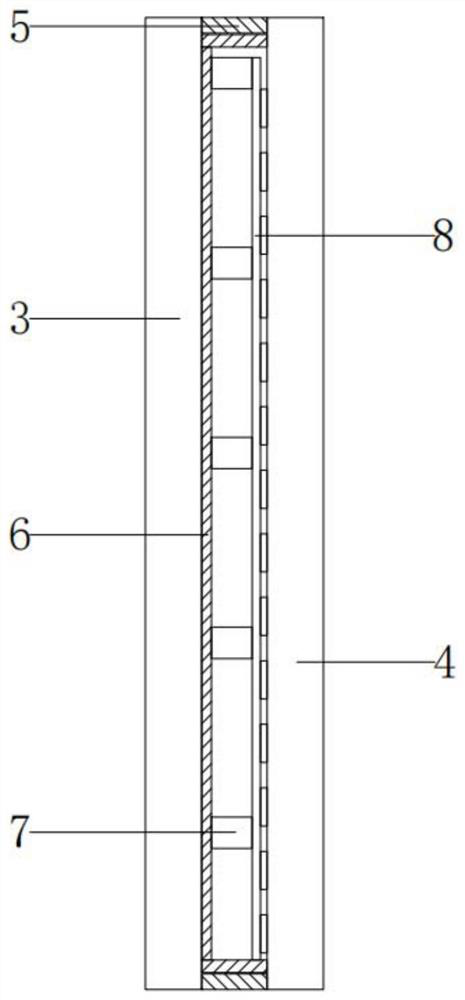

[0025] See Figure 1-5 , The present invention provides the following technical solutions:

[0026] A self-luminous glass comprising a frame 1, a fixing groove 2 is excavated on the inside of the frame 1, and a front substrate glass 3 and a rear cover glass 4 are sequentially arranged in the fixing groove 2 from front to back. One of the front substrate glass 3 and the rear cover glass 4 Between the front substrate glass 3 and the rear cover glass 4, a light strip 5 is provided, the rear end of the front substrate glass 3 is provided with a conductive circuit 6, and the front substrate glass 3 and the rear cover glass 4 are fixedly connected A plurality of LED point light sources 7, the LED point light sources 7 and the conductive circuit 6 are electrically connected, the plurality of LED point light sources 7 and the rear cover glass 4 are fixedly connected with an EVA film 8, and the rear end of the front substrate glass 3 is coated with The frame 9 is provided with passive lum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com